Consider Wool an Eco-Friendly Industrial Material

- Published: July 29, 2024

By David F. Erb Jr., President, Edward H. Best Co.

Wool is an incredible material which can do things that are very hard to replicate with synthetic materials. When specifying an engineering grade material, we often seek properties like fire retardance, high temperature, non-melting, anti-bacterial/anti-fungal, wicking properties or water repellant properties — all things that natural wool brings to the table inherently.

Wool has been around since the beginning of recorded history. Its use dates back thousands of years, with evidence of its cultivation found in archaeological sites across the globe. Early civilizations relied on wool to craft protective garments that shielded them from harsh climates and prized its warmth and comfort.

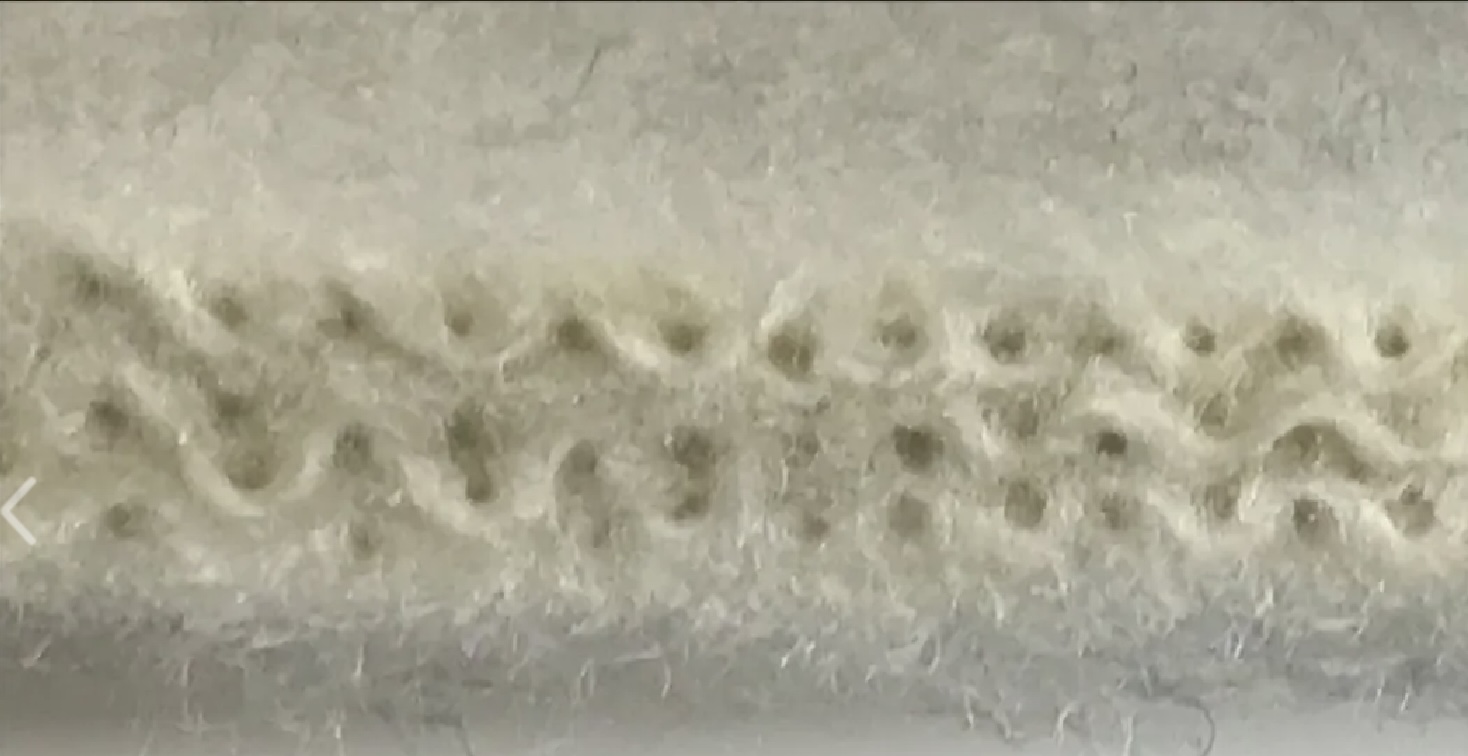

What sets wool apart from other fibers is its remarkable combination of properties. Its natural crimp and unique surface provide a "self-densifying" effect that can be manipulated for adjusting the pore size and thus the tunability in the effectiveness for wicking, insulating and acoustic properties.

Moreover, wool possesses a unique resilience that allows it to retain its shape and elasticity over time. Unlike synthetic fibers that may lose their form with repeated wear, UV degradation, fatigue or hydrolysis, wool maintains its integrity, ensuring longevity and durability in industrial applications.

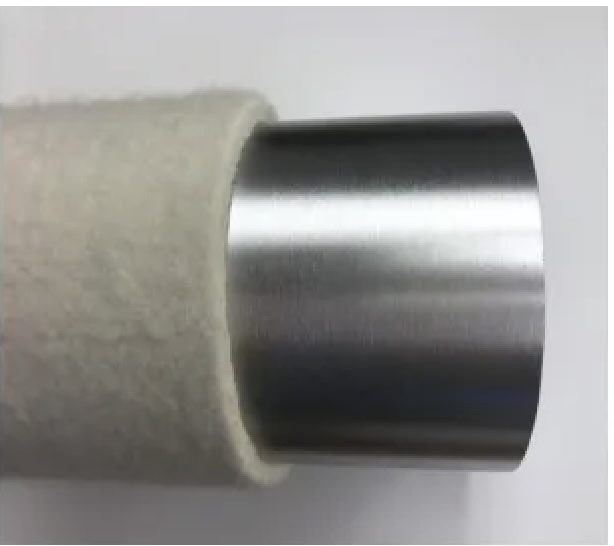

Roll Covers

Wool's versatility extends to its use in rollers and roller covers where its unique properties make it an excellent choice for a wide range of applications. Wool rollers are recognized for their durability, resilience and the ability to provide uniform pressure and coverage.

To achieve this property, wool roller covers are typically manufactured from endless woven and seamless cloth that is "felted" (essentially extremely entangled fibers) which creates a nearly homogeneous material. The product is typically stretched wet and dried, which creates a stable and subsequently shrinkable product when water is applied. This shrinkage can be significant and typically grips the substrate roller with tremendous force, again another unique property of wool.

In printing and textiles industries, wool rollers are commonly employed for their exceptional ink absorption and transfer capabilities. The natural absorbency of wool fibers ensures consistent ink distribution, resulting in high-quality prints and dyed fabrics. Again, wool's resilience allows rollers to maintain their shape and surface integrity, minimizing wear and tear over prolonged use.

In manufacturing and processing, wool rollers play a crucial role in materials handling and surface finishing applications. Their soft yet robust nature makes them ideal for conveying delicate materials without causing damage, scratches or mark-off.

In paper production and converting, wool rollers are employed for their superior traction and grip properties. The natural friction of wool fibers ensures efficient feeding and tension control, enhancing productivity and minimizing downtime.

Conveyor Belts

In conveying applications, wool belts offer a unique solution for materials handling. The fiber's natural resilience and frictional properties make it ideal for conveying delicate or irregularly shaped items without causing damage. The soft fibers provide gentle support while maintaining excellent grip and traction, ensuring smooth and efficient movement along the conveyor system.

Additionally, wool's moisture-wicking abilities help prevent slippage and maintain product integrity in humid or wet conditions. With durability, sustainability and versatility, wool conveyor belts offer a reliable and eco-friendly solution for industries ranging from food processing to textiles, where precision handling and product protection are paramount.

Polishing and Buffing

Wool's natural properties make it ideal for polishing and buffing applications. Its soft yet resilient fibers effectively remove imperfections and create a smooth, glossy finish on a variety of surfaces, including metals, plastics and wood. Wool polishing pads provide consistent surface pressure and application of compounds, ensuring uniform results without scratching or marring the surface. Additionally, wool's high absorbency enables it to retain polishing compounds and lubricants in a predictable manner for automated processes.

Acoustics

For the factory, wool has notable acoustic qualities in its ability to absorb high-frequency sounds. Acoustic treatments utilizing wool have extremely good acoustic absorption properties which can be tailored to specific frequencies depending on the density achieved in fulling. The natural crimp and density of wool fibers create multiple air pockets within the material, which act as sound traps. As sound waves travel through the air and encounter these fibers, they are absorbed and converted into heat energy, thereby attenuating noise levels typically produced by industrial machinery.

Sustainability

In a society increasingly concerned with sustainability, wool emerges as a champion. Wool is a renewable resource which is biodegradable and recyclable. Sheep contribute to land conservation and carbon sequestration, further enhancing wool's eco-credentials. Wool has the unique ability to absorb and retain carbon dioxide from the atmosphere. The wool fibers contain a high percentage of keratin, which naturally captures carbon during the growth of the sheep. This carbon remains stored within the wool even after it's harvested, making wool products a potential carbon sink.

In conclusion, when designing a process, you might consider wool as an important choice in industrial applications using a material that has been around for thousands of years providing many of the engineering properties we seek in industrial applications. And when you do choose wool, consider the downstream effects and benefits of using an eco-friendly and sustainable solution to your process.

About the Author

David F. Erb Jr. is President of the Edward H. Best Co. in Thomaston, Maine. The company produces endlessly woven wool and synthetic textiles for applications around the globe ranging from products used in the production of automotive tires to wallpaper and laundry pods. Erb holds more than 20 patents in high performance materials including ballistic vests, aircraft insulations, aircraft seating and other technologies.