Static Dissipater Installation Affects Performance

- Published: August 22, 2022

How do we install static dissipaters so that they work? How do we know if they work?

By Dr. Kelly Robinson, Founder, Electrostatic Answers

Static can shock operators, cause materials to jam, damage our products and ignite a fire. Prevent these problems by installing static dissipaters. How do we know that a static dissipater works properly? How can we decide if one location is better than another for installing a dissipater?

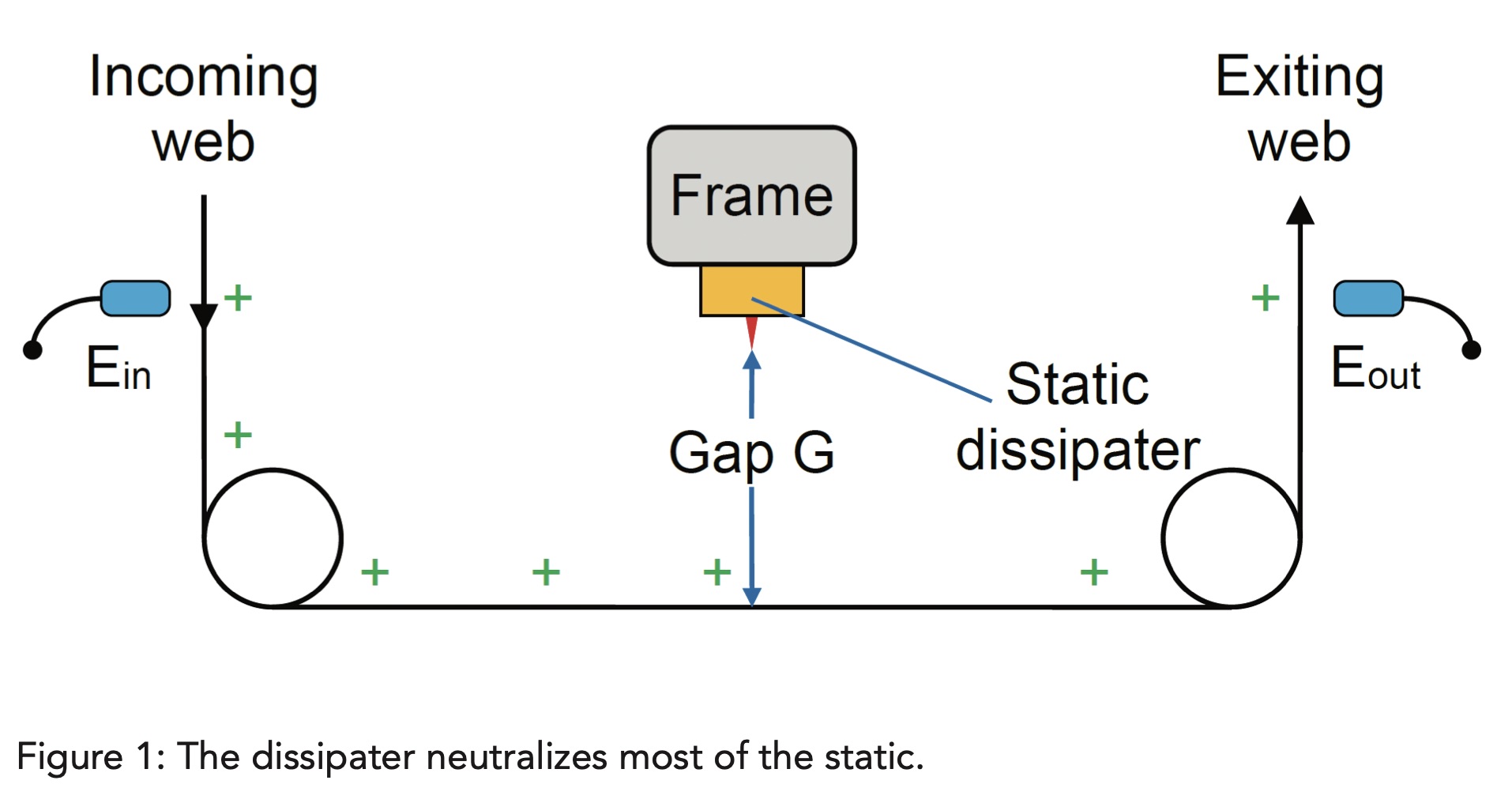

Neutralization efficiency measures the performance of the dissipater in Figure 1. We can define the neutralization efficiency h as the percentage of static dissipated.

For example, if we measure Ein in Figure 1 to be 5kV/cm and Eout to be 1 kV/cm, the neutralization efficiency h is 80 percent.

We want the neutralization efficiency to be 100 percent so that all of the static is dissipated. However, dissipaters are not perfect. The neutralization efficiency of tinsel, static brushes and other passive dissipaters should exceed 80 percent. Powered static bars should dissipate at least 95 percent of the static.

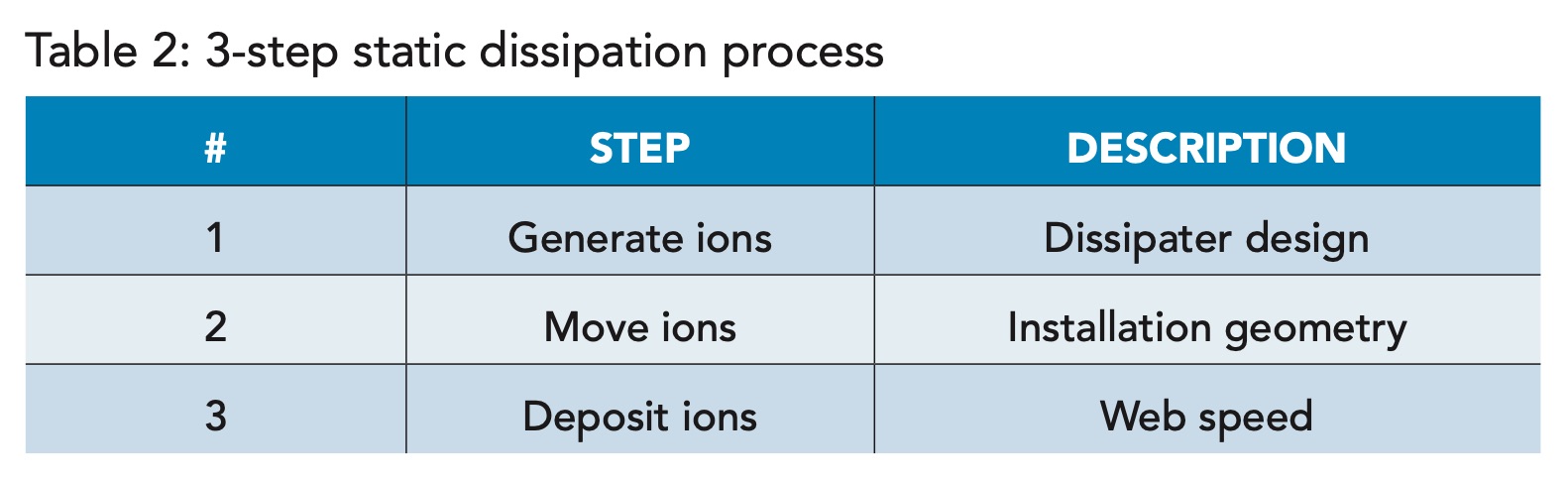

To get the best performance, think about dissipating static as the 3-step process in Table 2.

Most static dissipaters generate plenty of ions. Tinsel, static brushes and other passive dissipaters with sharper points or smaller bristles generate more ions. Powered static bars with more pins and that operate at higher voltages generate more ions.

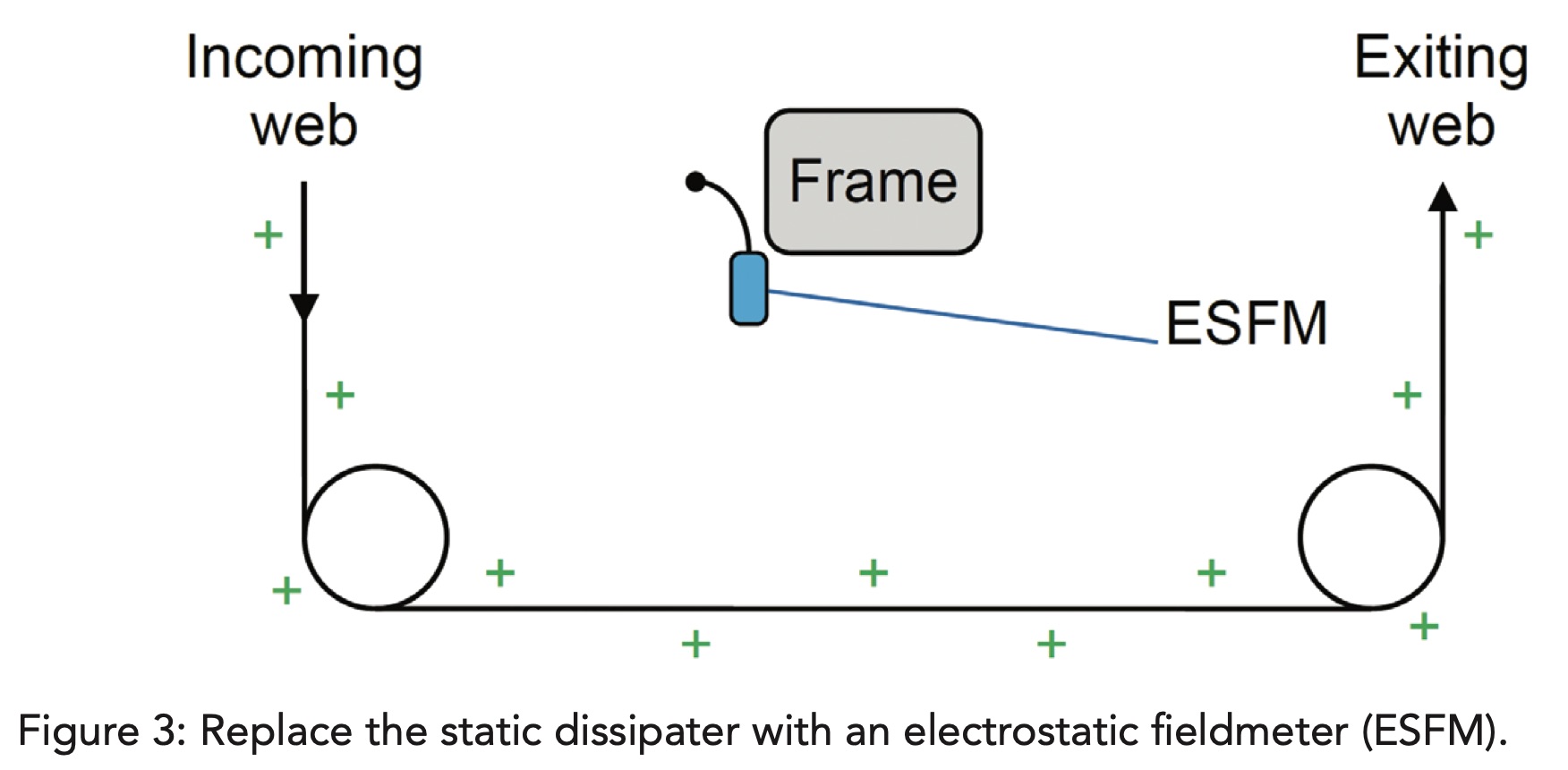

Moving the ions generated by the dissipater to the charged web is determined by the installation geometry. Install the dissipater so that it “sees” the static. By this, I mean that the electric fields from the static on the web must reach the dissipater. Imagine that we replace the static dissipater in Figure 1 with the electrostatic fieldmeter (ESFM) in Figure 3. If the ESFM responds to the static on the web, then the static dissipater will also respond to the static. And, if the ESFM reads zero when there is charge on the web, then the static dissipater will be ineffective.

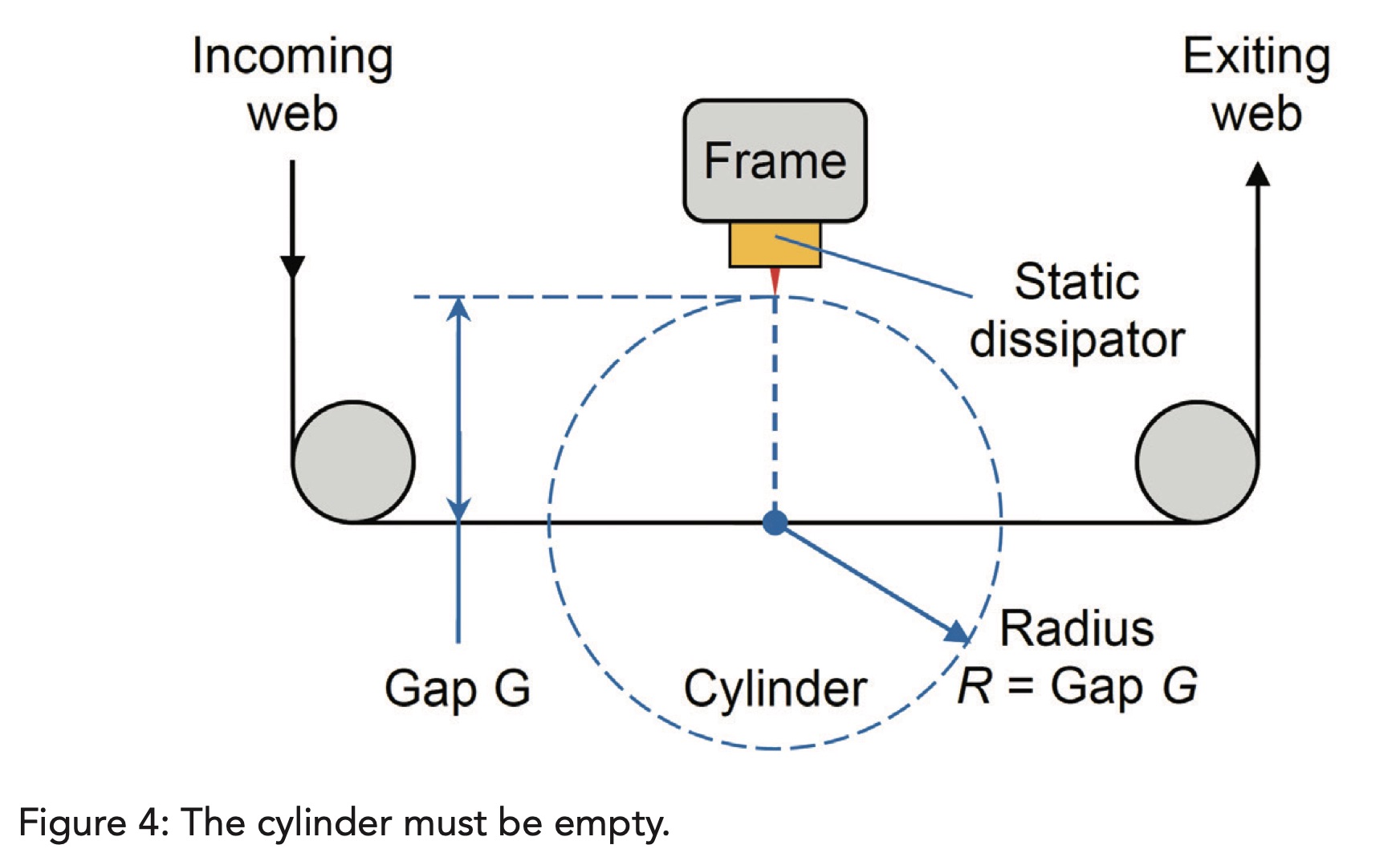

We can visually inspect the installation geometry to see if the static dissipater will work. In your mind’s eye, draw a pencil line across the web in Figure 4 below the static dissipater. The line becomes the center of a cylinder that expands out until it touches the dissipater. So, the radius of the cylinder will be gap G. This cylinder must be empty for the static dissipater to function properly.

The ions generated by the static dissipater move pretty fast through the air. For example, for a small electric field of 2 kV/cm (5 kV/in), ion move at about 40 m/s. Still, it takes some time for the ions to move from the dissipater to the web. If the gap G is 3 inches, ion reach the web in about 2 ms (0.002 s).

For good neutralization efficiency, the web speed Uweb should be slow enough for the web to be inside the cylinder 10 times longer than it takes for an ion to reach the web.

With a good installation, static dissipaters should work well at web speeds up to an estimated web speed of about 1,500 fpm.

Neutralization efficiency is a good metric for static dissipater performance. We can measure the neutralization efficiency of a dissipater using an ESFM to measure the static on the entering web and on the exiting web. When properly installed, the static dissipater is the closer to the web than everything else. And, when installed properly, static dissipaters should work well up to web speeds of about 1,500 fpm (~500 mpm).

For more information, contact This email address is being protected from spambots. You need JavaScript enabled to view it..