Automating Static Control with Online Monitors

- Published: June 12, 2023

By Dr. Kelly Robinson, Founder, Electrostatic Answers

Can we “automate” static control so that we do not have to devote time and resources to fighting static problems? Almost! An “automatic” system, once installed, runs reliably, needing only periodic maintenance. A well-designed static control system is “automatic” because it runs reliably, needs only periodic maintenance, and, with online sensors, ensures that finished products have acceptably low static.

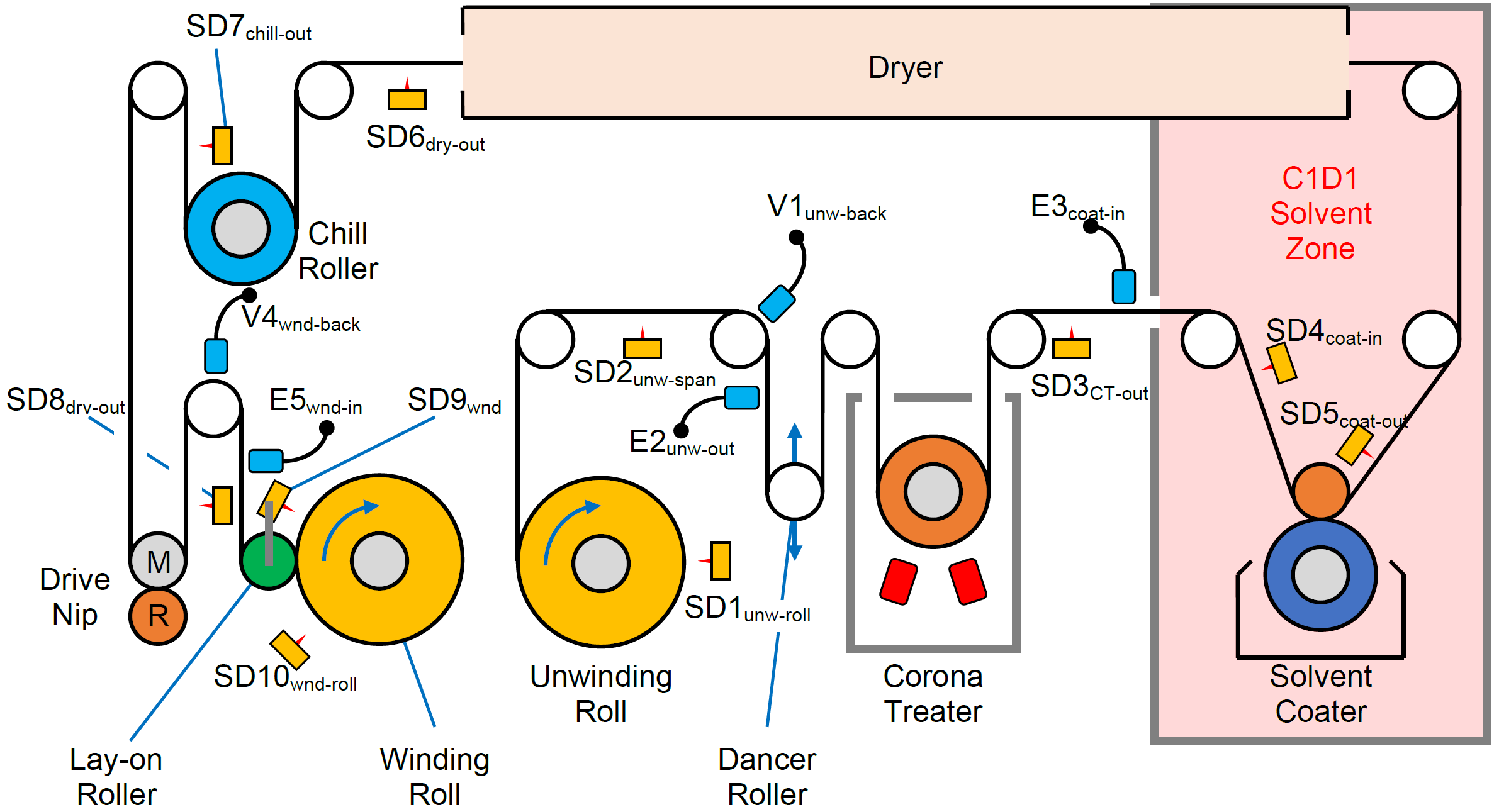

The static control system for the coater in Figure 1 including the online sensors accomplishes our three goals:

- Static is low entering the C1D1 Solvent Zone (safety - static sensitive area);

- Static is acceptably low entering the winding roll (quality - finished product);

- The static control system functions properly (production reliability).

Each of the static control elements serves a specific purpose. Static Dissipater SD1unw-roll neutralizes static charges on the outside surface of the unwinding roll. Unwinding rolls can store large amounts of static charge from the operation where the roll was wound. This static dissipater needs to be a high-performance, long-range static bar because, as the unwinding roll expires, the distance from the static bar to the surface of the roll increases.

SD2unw-span neutralizes static charges on the inside surface of the web exiting the unwinding roll. This static bar can be a short-range static bar because the distance from the static bar to the web is fixed.

An electrostatic voltmeter (ESVM) and an electrostatic fieldmeter are two different, complementary instruments. An ESVM respond to the charge density on the exposed surface of the web wrapped on a grounded idler roller. An ESFM respond to the sum of the charge densities on both sides of the web.1

Online electrostatic voltmeter (ESVM) V1unw-back verifies that SB1unw-roll is functioning properly by measuring the static charges on the outside surface of the web exiting the unwinding roll. The average reading should not exceed ±0.5 V/um of web thickness. For example, for a 2 mil (50 um) thick web, the average reading should not exceed ±25 V.

Online electrostatic fieldmeter (ESFM) E2unw-out verifies that SB2unw-span is functioning properly by measuring the net charge on the web exiting the unwinding roll. The average reading should not exceed ±0.5 kV/cm (±1.3 kV/in).

Powered static dissipater SD3CT-out neutralizes static charges on the treated surface of the web exiting the corona treater. A corona treater can deposit a very large amount of static charge on the treated surface of a web.

Online ESFM E3coat-in serves two purposes. First, it ensures that static is low entering the static sensitivity C1D1 Solvent Zone. Second, E3coat-in verifies that SD3CT-out functions properly. The average reading should not exceed ±0.5 kV/cm (±1.3 kV/in).

Powered static dissipater SD4coat-in protects the C1D1 Solvent Zone if SC3CT-out fails. Normally, the web entering the C1D1 Solvent Zone is charge-free. However, if SB3CT-out should fail, the risk of a static spark is high from static charges on the web deposited by the corona treater.

Powered static dissipater SD5coat-out neutralizes static charges on the web from touching the backing roller especially at the end of a run when coating stops. Powered static dissipater SB6dry-out neutralizes static charges on the back side of the web exiting the dryer. The back-side idler rollers in the dryer can deposit significant amounts of static charges on the web. (“Static Control for Dryers,”2.)

Powered static dissipater SD7chill-out neutralizes static charges on the web exiting the chill roller. Chill rollers can deposit significant amounts of static on web surface that touches the roller. Powered static dissipater SD8drv-out neutralizes static charges on the web surface that touched the rubber nip roller. Nip rollers can deposit large amounts of static charges on the web surface that touches the rubber nip roller.

Online ESVM V4wnd-back serves three purposes: First, it verifies that SD6dry-out functions properly by measuring the static charges on the back side of the web; Second, comparing V4wnd-back with V1unw-back verifies that the static dissipaters between these two measurements are all functioning properly; Third, if verifies that static charges on the back side of the web entering the winding roll are acceptably low. The average reading should not exceed ±0.5 V/um of web thickness. For example, for a 2 mil (50 um) thick web, the average reading should not exceed ±25 V. And, the average difference ΔV = (V4wnd-back‒V1unw-back) should not exceed ±0.5 V/um of web thickness.

Online ESFM E5wnd-in serves two purposes. First, it verifies that SD8drv-out is functioning properly. Second, it verifies that the net static charge on the web entering the winding roll is acceptably low. The average reading should not exceed ±0.5 kV/cm (±1.3 kV/in).

Powered static dissipater SD9wnd neutralizes static charges on the outside surface of the winding roll from touching the lay-on roller. The winder lay-on roller deposits static charges on the web surface that touches the roller. This static dissipater may be mounted to the bracket holding the lay-on roller so that the distance from the static bar to the winding roll remains constant.

Powered static dissipater SD10wnd-roll neutralizes static charges on the outside surface of the winding roll if SD9wnd should fail. SD9wnd is prone to failure caused by mechanical vibrations. Together, static dissipaters SD9wnd and SD10wnd-roll effectively neutralize static charges on the finished product.

Install online monitors for three reasons: 1) Safety - Ensure that static charges are low entering sensitive areas; 2) Product Quality - Verify that static levels are acceptably low on finished product; and 3) Production Reliability - Make sure that the static control system is functioning properly.

1 https://ieeexplore.ieee.org/stamp/stamp.jsp?tp=&arnumber=9915453

2 https://cloud.3dissue.net/33877/33789/34113/91696/index.html

ABOUT THE AUTHOR

Kelly Robinson, PE, Ph.D., is the owner of Electrostatic Answers, an engineering consulting company dedicated to eliminating injury and waste from static electricity. You can reach Kelly directly at This email address is being protected from spambots. You need JavaScript enabled to view it..