Bimec and Flex CA Strengthen U.S. Market Presence with a new installation at Cello-Wrap Packaging Inc.

- Published: April 17, 2025

Bimec and Flex CA proudly announce a new milestone in their U.S. market expansion with the recent commissioning of a state-of-the-art slitter rewinder at Cello-Wrap Packaging Inc, located in Farmersville - TX.

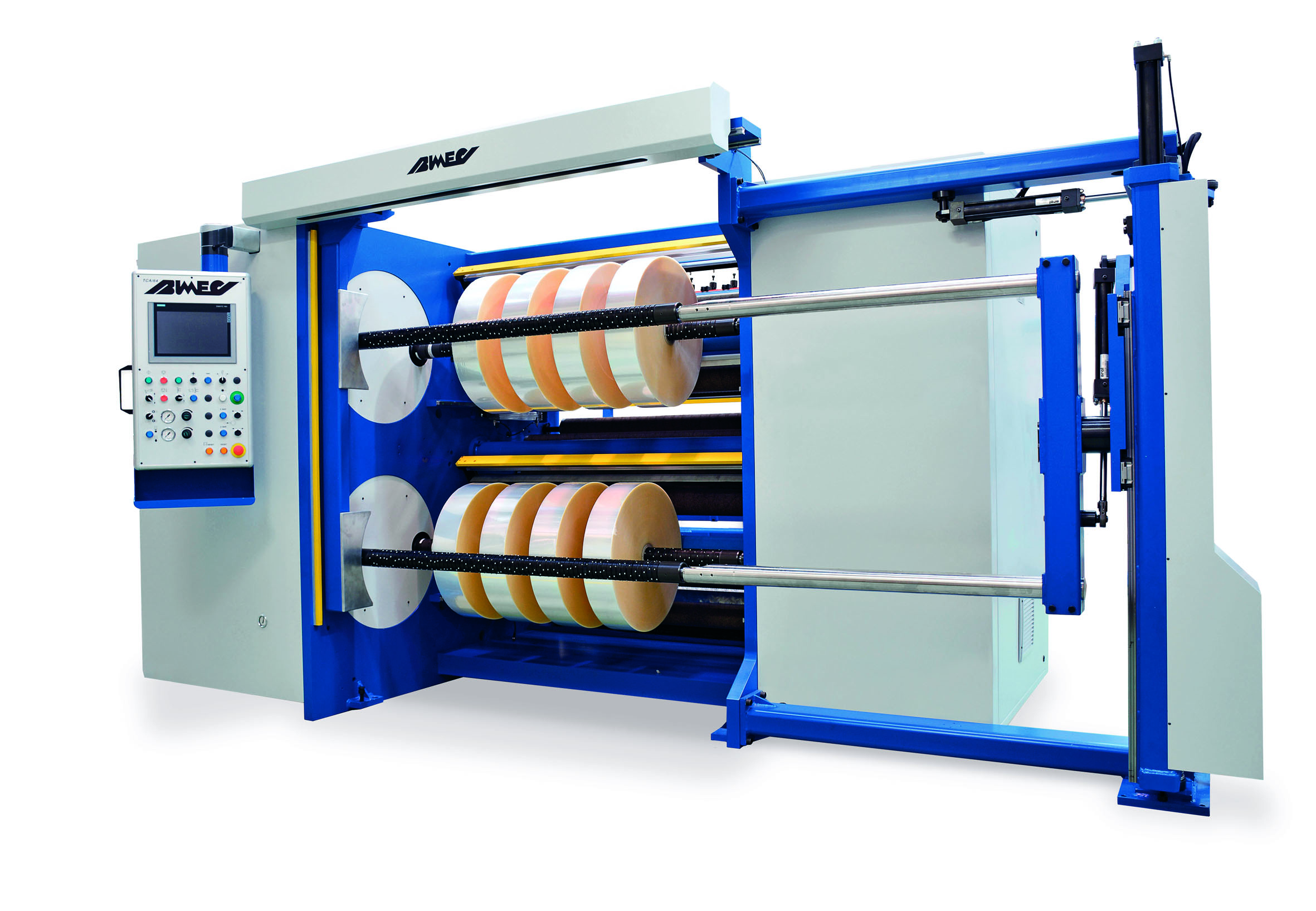

At the center of this achievement is the TCA — Bimec’s fully Automatic Duplex Turret Slitter Rewinder.

Designed with a main focus on high productivity, advanced automatisms and operational versatility, the TCA represents the next generation of slitting technology for the converting industry.

Its seamless integration into Cello-Wrap’s production line reflects both companies’ commitment to efficiency, quality and innovation.

The customer, already operating two old slitter rewinders from other brands, was looking to install a new slitter rewinder to boost productivity and minimize downtimes. Following an initial phase of technical consultancy to assess the customer's specific requirements, Bimec invited Cello Wrap to its headquarters to visit the production facilities and see the TCA 64C+ in operation.

During the trials at Bimec, the customer had the opportunity to personally check the machine’s high performance and advanced automation features, the superior quality of the raw materials used, resulting in a robust, durable system built for long-term operation.

The Duplex Turret Slitter Rewinder TCA 64C+ distinguishes itself with a compact design, the semi-integrated unwinding carriage, which provides easy access to the slitting area while minimizing the risk of material contamination from dust particles.

It is engineered for both razor blade and pneumatic circular knife slitting, and incorporates multiple automation systems, including the automatic knife holder positioning system and multi-groove female knifes, which are combined with the automatic single laser beam for core positioning and a reel unloading station that automates the opening, closing and rotation of the side stand arms.

Successfully delivered and commissioned at the end of February 2025, the TCA 64C+ has 1650 mm of web width, handles mother rolls with a diameter of up to 1000 mm, rewinds finished rolls up to 610 mm and operates at 800 m/min speed — ensuring rapid roll loading and unloading and significantly enhancing overall production efficiency.

This collaboration marks more than the delivery of advanced equipment, it stands for the beginning of a valued partnership built on shared goals and mutual trust. The decision by Cello-Wrap to invest in this high-performance solution affirms confidence in the reliability and performance of Bimec slitting equipments and Flex CA’s converting solutions.

About Bimec and Flex CA

Bimec, a globally recognized name in slitting and rewinding solutions 100% Made in Italy and with almost 50 years of activity in this field.

FLEX CA is an alliance of companies through binding equity agreements to offer best-in-class products to the converting industry, covering extrusion, printing, quality control and slitting equipment.

Per maggiori informazioni: www.bimec.it - www.flexca.com