How Flexo Printers Can Help Brands With Green Initiatives

- Published: April 23, 2020

By: Rodney Pennings, Director of Sales, Paper Converting Machine Company

With increased concerns about the environment, consumers are now pushing brands to use sustainable practices more than ever. In fact, 66 percent of consumers and 73 percent of millennials are willing to pay more for sustainable goods, according to research by Nielsen.

With increased concerns about the environment, consumers are now pushing brands to use sustainable practices more than ever. In fact, 66 percent of consumers and 73 percent of millennials are willing to pay more for sustainable goods, according to research by Nielsen.

As a result of changing consumer demands, many brands are reevaluating their practices and looking for ways to become more sustainable, focusing on product packaging and plastic reduction in particular.

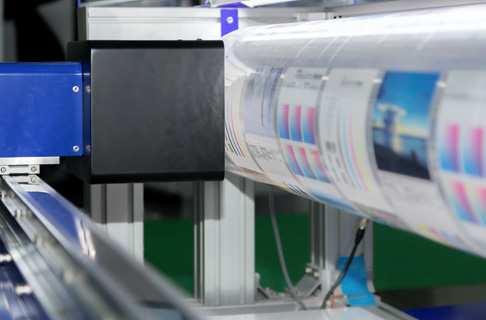

Flexographic printing has helped change the packaging industry as it allows for printing on a wider range of materials than traditional printing presses. With flexographic printing, brands can utilize flexible packaging or recyclable materials without losing print quality or efficiencies when choosing new packaging.

Flexo printers have valuable opportunities to help brands meet those sustainability initiatives. Below are a few ways to reach brands looking to go green.

Choose a Press Optimized for Flexible and Recyclable Packaging

Printing press technology and design play a crucial role in achieving quality and providing efficiencies. Some printing presses are optimized for printing on unique substrates such as polyethylene, which is recyclable and requires less plastic to produce. Previously, polyethylene and low gauge films could be barriers to quality printing, as they are thin and difficult to print on.

Now, some flexo printing presses offer high-quality printing capabilities on these materials. New presses can achieve near CI-quality on polyethylene and low gauge films, which means printers can offer brands the opportunity to reduce their use of plastic and increase packaging recyclability without sacrificing quality.

Automated presses contribute to a more eco-friendly process, as well, featuring low power consumption and ink savings. Some presses can even save 50-75% of waste throughout the printing process, reducing heat and air and ink loss. By utilizing technologies like these, printers offer brands a way to decrease the overall waste produced during the packaging of their products.

Use Less Water and Fewer Chemicals

Flexo printers can also support sustainability initiatives by using water- and solvent-saving printing and cleaning processes, which reduces water waste and contamination. Laser cleaning is one way to reduce the use of water and chemicals, as laser cleaners don't require liquids, chemicals or air supplies, yet achieve deep cleaning and provide better print quality. Flexo printers implementing methods like these help brands reach their goal of contributing to a cleaner environment.

Use Less Energy

Traditionally, flexo printers have used heat, which can end up using a high amount of energy. But, air compression offers a way to dry ink without the need for gas or burners, which naturally lowers energy consumption.

This method can produce up to 180 degrees of heat for drying without burning fuel. Air compression can be supplemented with conventional heating for faster drying but still cuts the amount of energy needed for the process, as over half of the heat required is produced without fuel. Printers that opt for a press that uses air compression for drying can provide customers with a way to contribute to overall energy savings in their processes.

Utilize Sustainable Inks

Water-based inks are an eco-friendly alternative to solvent-based inks, as they include fewer volatile organic compounds, which can be hazardous or have implications for the environment when evaporated into the air. Water-based inks are made from renewable resources. No fossil fuels or petroleum are required to produce them and no chemicals are required for cleanup, which helps prevent hazardous materials from entering the water supply. Printing with water-based inks helps printers and brands alike get closer to their sustainability goals.

Innovative Equipment Makes it Happen

The right printing press can reduce waste and save on energy and water consumption while providing superior printing quality. Flexographic printers can gain a leading edge in the industry by taking advantage of these advancements to technology.