Leveraging New Technology for Advancements in Battery Electrode Manufacturing

- Published: February 27, 2025

Machine designers and process engineers in the battery industry are witnessing a pivotal shift towards more space-efficient, precise, and adaptable manufacturing processes. In parallel processing applications, manufacturers are increasingly focused on achieving more electrode lanes per machine, while integrating advanced sensor technologies to meet the growing demand for high-quality batteries used in EVs and grid storage applications.

Space Optimization in Multi-Lane Setups

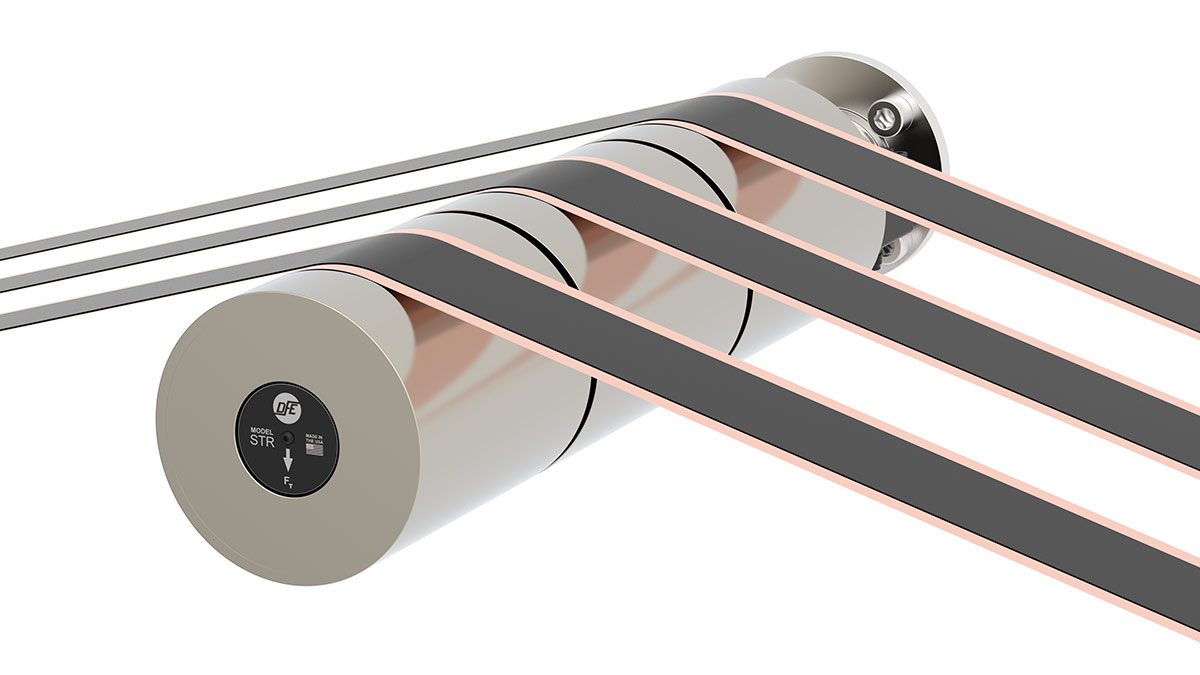

The challenge of managing multiple lanes within the limited space of manufacturing lines is being addressed through innovative solutions like DFE’s Segmented Tension Roll® Transducer. This device allows for the precise measurement and control of tension across multiple web strands with a single, compact unit. By eliminating the need to deploy a large array of individual tension sensors, it significantly reduces the machinery footprint, enabling battery manufacturers to increase production capacity and enhance operational efficiency without expanding physical space. Segmented roller systems can be configured from two to ten rollers in various arrangements, including mirrored up-down installations perfect for inline slitting applications.

Precision and Flexibility with Semiconductor Strain Gauge Technology

Precision and Flexibility with Semiconductor Strain Gauge Technology

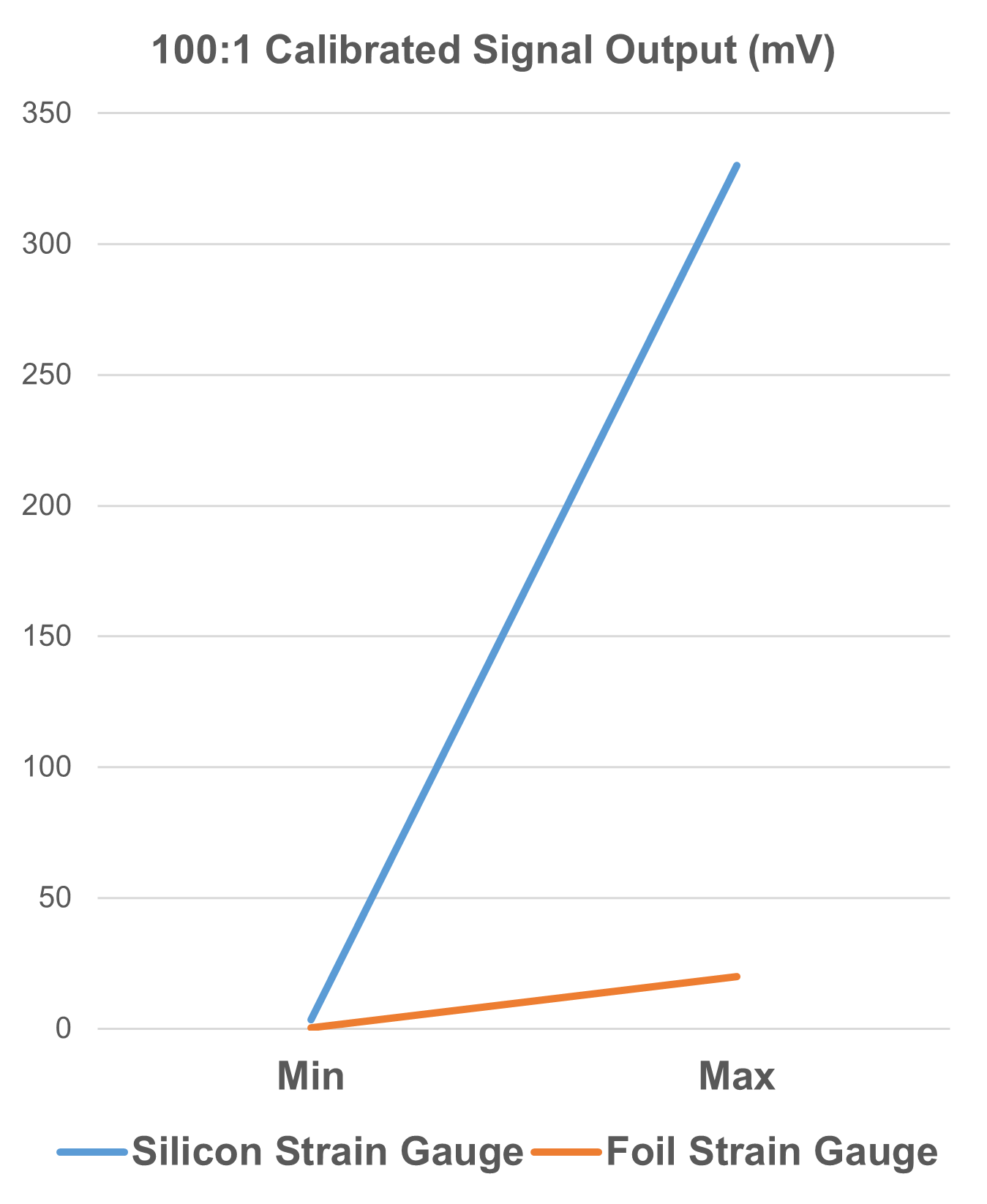

Precision in tension control is crucial for producing electrodes with consistent thickness and quality. The integration of semiconductor strain gauge technology within these tools provides engineers with a load cell system that delivers up to 50 times more sensitivity than foil gauge sensors. Semiconductor gauges are uniquely suited to detect and adjust to the slightest shifts in tension, even in the presence of high EMI. This sensing technology not only ensures optimum coating, calendaring or slitting across all lanes, but also the flexibility to adapt to different chemistries, substrates or process conditions as manufacturing needs evolve over time.

Enhanced Control Signals for PLCs

Low-latency signals are crucial for closed-loop systems where immediate feedback and control is necessary to maintain the integrity of delicate electrode coatings and substrates, particularly at high processing speeds. Many load cell amplifiers use ADCs that rely on components such as gain blocks to boost the signal performance of lower output foil gauge load cells. As a result, these high-gain signals contain significant noise that must be conditioned with techniques such as low-pass filters. Typically, this filtering approach results in increased signal delay which can deliver “choppy” or sluggish output, adding significant latency to data streams.

In contrast, the synergy between DFE’s Segmented Tension Roll® and latest TA500 amplifier has transformed what’s possible for tension measurement. TA500 amplifiers with advanced 24-bit ADCs down-convert signals to 16-bit in real-time, sending noise-free raw data from each roll segment directly to the ethernet bus. This advantage is possible due to the direct hand-off from semiconductor load cells to the amplifier’s ADC without the need for additional pre or post-processing.

Integration and Implementation

For engineers and machine-builders, integrating these technologies into existing setups has become easier than ever. Segmented roller systems are designed for easy retrofitting or integration on new machines, with each segment capable of independent calibration and load ratings to cover a wide range of applications. Low-latency amplifiers serve as the backbone for processing sensor data, ensuring that PLCs can react with maximum speed and precision by tapping directly into ADC registers. The simplicity of the overall system also reduces space requirements and fabrication complexity, while enabling an increased number of sensor touchpoints throughout the production line.

Practical Benefits for Battery Manufacturing Applications

- Consistent Quality: By ensuring uniform tension across multiple lanes, the risk of defects like uneven coating or material stretching is minimized, leading to higher quality electrodes and increased yields.

- Operational Efficiency: The ability to quickly recalibrate or adjust tension for different materials or process requirements enhances the line's adaptability to production changes, reducing downtime and increasing throughput.

- Space and Cost Savings: The compact nature of solutions like the Segmented Tension Roll® means less space is required for tension management, enabling smaller machine footprints and greater manufacturing density.

Future Directions

The adoption of these technologies signals a broader industry trend towards smarter, more integrated manufacturing solutions. As battery demand continues to grow, especially with the trend toward EVs and renewable energy storage, the focus on space efficiency, responsiveness, and process adaptability will only intensify. For engineers tasked with optimizing battery machinery, systems such as the Segmented Tension Roll® are not just tools but enablers of future progress, providing the means to push production standards and efficiency to a higher level.

About The Author

Dover Flexo Electronics is a leading manufacturer of high-performance tension control systems used in a wide variety of applications and industries. For more information, visit www.dfe.com or email This email address is being protected from spambots. You need JavaScript enabled to view it..