Optimize PEM Fuel Cell Loadings with Continuous Monitoring & Control

- Published: October 09, 2024

Fuel cell manufacturers face significant challenges, particularly high production costs. One reason for these high costs is the need for frequent offline analysis of fuel cell loadings. When manufacturers use offline analysis, production stops. They may also experience costly waste because quality issues are not promptly identified and resolved. NEX LS solves this problem by enabling continuous monitoring and control of platinum, iridium, or other loadings used in PEM fuel cell production.

NEX LS provides on-line profiling of the substrate or loading, allowing you to identify quality issues immediately. This real-time analysis reduces downtime and helps you avoid costly scrap or waste. Whether monitoring Pt, Ir, or exploring other fuel cell loadings, NEX LS provides:

- Continuous monitoring of loadings to identify critical defects immediately — NEX LS is an in-line system that streamlines production processes. It reduces the need for offline analysis or at-line checks, reducing downtime.

- Tighter control tolerances, reducing costs — Platinum, iridium, or other loadings used in PEM fuel cell production are expensive. Improper loadings can impact the overall cost of a fuel cell. With NEX LS, you can easily set control parameters to alarm for variations in the uniformity of the catalyst material.

- A clear visual representation of your entire process — It is crucial to carefully control the loadings and ensure that they are applied evenly and consistently. Changes in coating thickness or uniformity can affect the fuel cell’s performance and durability. In addition to real-time process control, NEX LS offers advanced roll reporting capabilities for quality records or audit trails.

How does NEX LS work?

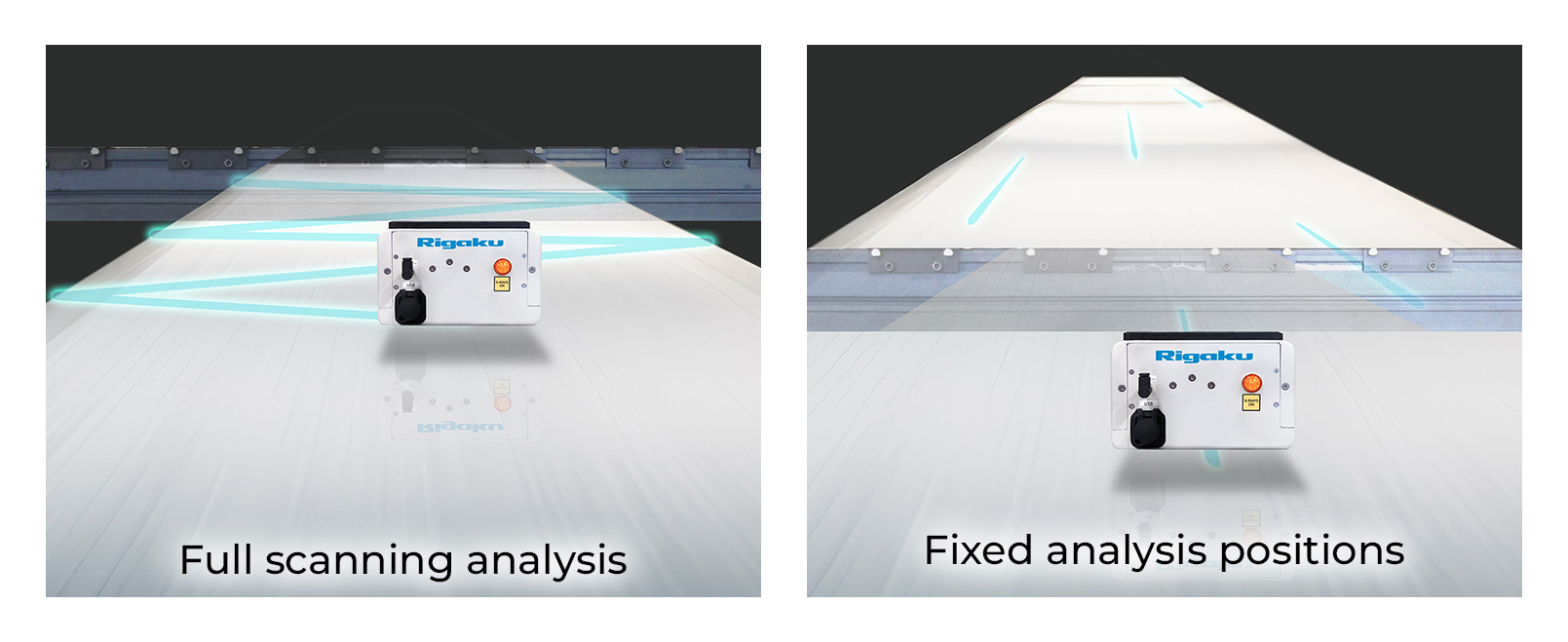

NEX LS is a compact, in-line EDXRF system easily installed and customized to meet process control needs for roll-to-roll (R2R) applications. Its analytical head sweeps back and forth across a moving web, and real-time data is displayed as a graphical cross-direction and machine-direction profile. You can choose full scanning mode or user-defined fixed analysis positions. Features include:

- Cross machine and machine direction profiling

- Easy self-installation configured to meet your process control needs

- Easy automatic calibration and operation

- Roll reporting capabilities for quality records or audit trails

- Minimal routine maintenance and 2-year warranty

Learn More About NEX LS

NEX LS offers a compelling solution to address the high costs associated with PEM fuel cell loadings. By providing real-time data and enabling proactive process control, it can streamline production processes, reduce costs, and ensure consistent product quality. Contact This email address is being protected from spambots. You need JavaScript enabled to view it. to learn more about NEX LS.