Faustel – Battery Energy and Fuel Cell Market Q&A

- Published: June 25, 2024

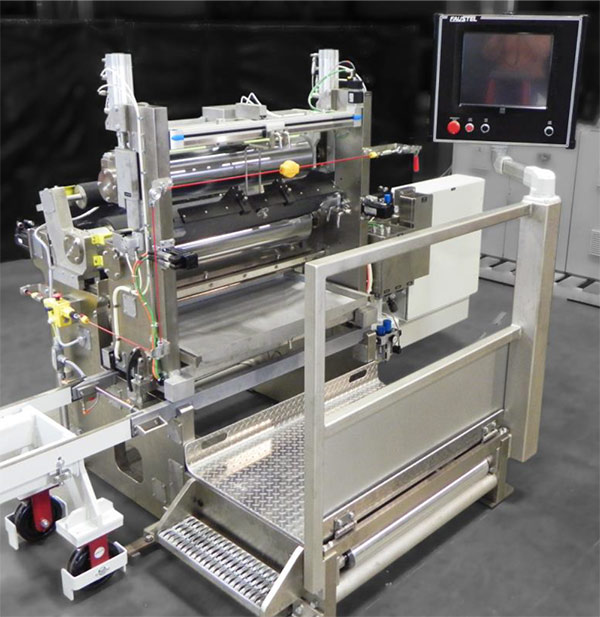

Faustel is the technology leader in custom roll to roll electrode, fuel cell, and battery separator production equipment solutions, with over 65 years of experience in precision coating, laminating, and winding machinery. Flexible designs with modular components are configured to meet specific process requirements in either single or double pass systems, and can be built to clean room and dry room standards. Faustel's process and technology expertise includes proficiency with integrating convection drying, UV, LED, and nIR systems, along with calendars, gauging systems, and coating delivery systems. Advanced machine control integration assures precise web handling, seamless process control, data collection, and ease of operation using your choice of Siemens or Rockwell platforms.

Faustel is the technology leader in custom roll to roll electrode, fuel cell, and battery separator production equipment solutions, with over 65 years of experience in precision coating, laminating, and winding machinery. Flexible designs with modular components are configured to meet specific process requirements in either single or double pass systems, and can be built to clean room and dry room standards. Faustel's process and technology expertise includes proficiency with integrating convection drying, UV, LED, and nIR systems, along with calendars, gauging systems, and coating delivery systems. Advanced machine control integration assures precise web handling, seamless process control, data collection, and ease of operation using your choice of Siemens or Rockwell platforms.

To provide an overview of Faustel’s experience, and involvement in the industry, we recently had a conversation with Chris Clark, Faustel’s Vice President of Sales and Technology.

What has been Faustel’s experience in the quickly growing battery energy and fuel cell markets?

Faustel has been heavily involved in these dynamic market segments for over a decade, providing equipment from pilot scale to production scale, with customers ranging from newly incorporated start-ups to the world’s leading product manufacturers. Because the technology is rapidly evolving, there is never a dull moment, with each new project bringing unique product requirements and process challenges.

What other web-based products does Faustel manufacture equipment for?

We have a strong presence in many different market segments such as roofing materials, tapes and labels, packaging laminations, filtration membranes, aerospace laminates, medical products, and pharmaceutical coatings.

What makes Faustel a strong partner?

What makes Faustel a strong partner?

At its core, Faustel is an engineering company. We have a solid foundation of equipment design and controls integration experts, most having decades of converting industry experience. Our approach leverages the team’s extensive knowledge base, and then applies the latest, high-quality components available in the market to ensure consistent performance and optimal results. Our highly experienced staff also includes machine assembly technicians who are able to provide installation supervision services if needed.

How does Faustel support customers in their ongoing product development work?

Faustel’s state of the art in-house Process Technology Center is a unique competitive resource in the industry, available for customer development trials. We have three different coating lines, from R&D scale to production scale, capable of trialing both aqueous and solvent based products. By collecting trial data for evaluation, we facilitate the equipment design process, as well as customer product optimization. Our process staff has significant experience, conducting over 100 trials related to batteries and fuel cells. As part of our value proposition, Faustel includes trial time at our Technology Center as part of every machine purchase.

After the machine is commissioned, what kind support does Faustel offer?

After the machine is commissioned, what kind support does Faustel offer?

I believe our warranty is the best in the industry, and if there is an equipment problem in the first two years, we will take care of it. For the many Faustel machines that are several decades old, our MRO parts department is very adept at finding replacement components if they are needed. In addition, our service team is available to conduct machine audits of older Faustel equipment, providing a report detailing the condition of each machine section, including the control system. Recommendations are made for component replacement and feature upgrades to current technology, to help keep things running for decades to come.

What does Faustel’s future look like?

Although deeply rooted in our strong history, Faustel continues to be a dynamic organization, focused on being successful in the opportunities we see with emerging technologies and evolving product markets. We continue to build on resilient partnerships, both with suppliers of component technology, and with our growing customer base. Maintaining our strong reputation for the highest quality equipment and unparalleled service is paramount. Continuing to support our team to be their best on every project helps to keep our focus on building success one day, and one customer, at a time.

For more information, contact www.faustel.com