LED Curing Set to Take Spotlight for 2023, According to Flint Group

- Published: April 10, 2023

The year 2023 is shaping up to be the year of conversion to LED curing for label and narrow web packaging printers, says leading global print consumables manufacturer, Flint Group.

The year 2023 is shaping up to be the year of conversion to LED curing for label and narrow web packaging printers, says leading global print consumables manufacturer, Flint Group.

The business notes a drive towards LED curing over traditional UV methods and believes that while the adoption of LED has been slow and steady, market conditions, the cost of energy, and the evolving regulatory landscape is indicating an uptick in the rate of adoption – particularly in Europe.

Niklas Olsson, Global Director Product & Commercial Excellence, Narrow Web at Flint Group, explained: “Just a few years ago, the industry believed that LED curing could never match the quality or performance of UV curing and required significant investment. However, right here and right now, the case for LED curing has never been stronger, so it’s no surprise that we’ve seen businesses of every size making the transition.

“As brands and retailers seek sustainable supply chain partners to support their ESG objectives, achieving more sustainable printing is front and center for packaging and label printers worldwide. When we talk about LED curing, we talk reduced downtime driving enhanced productivity and the much lower energy use offered in comparison to UV curing – believed to be between 50-80 percent depending on light dissipation - is becoming an extremely attractive cost and sustainability benefit too.

“With today’s business environment and the cumulative benefits of LED, we’re clearly looking at the tipping point of real market-wide change. This is likely to intensify with global sustainability legislation limiting the use of mercury, which looks set to make UV lamps harder to acquire and dispose of. With LED curing offering lower cost in use, rapid speed, and high quality, it’s time to move the curing conversation forward.”

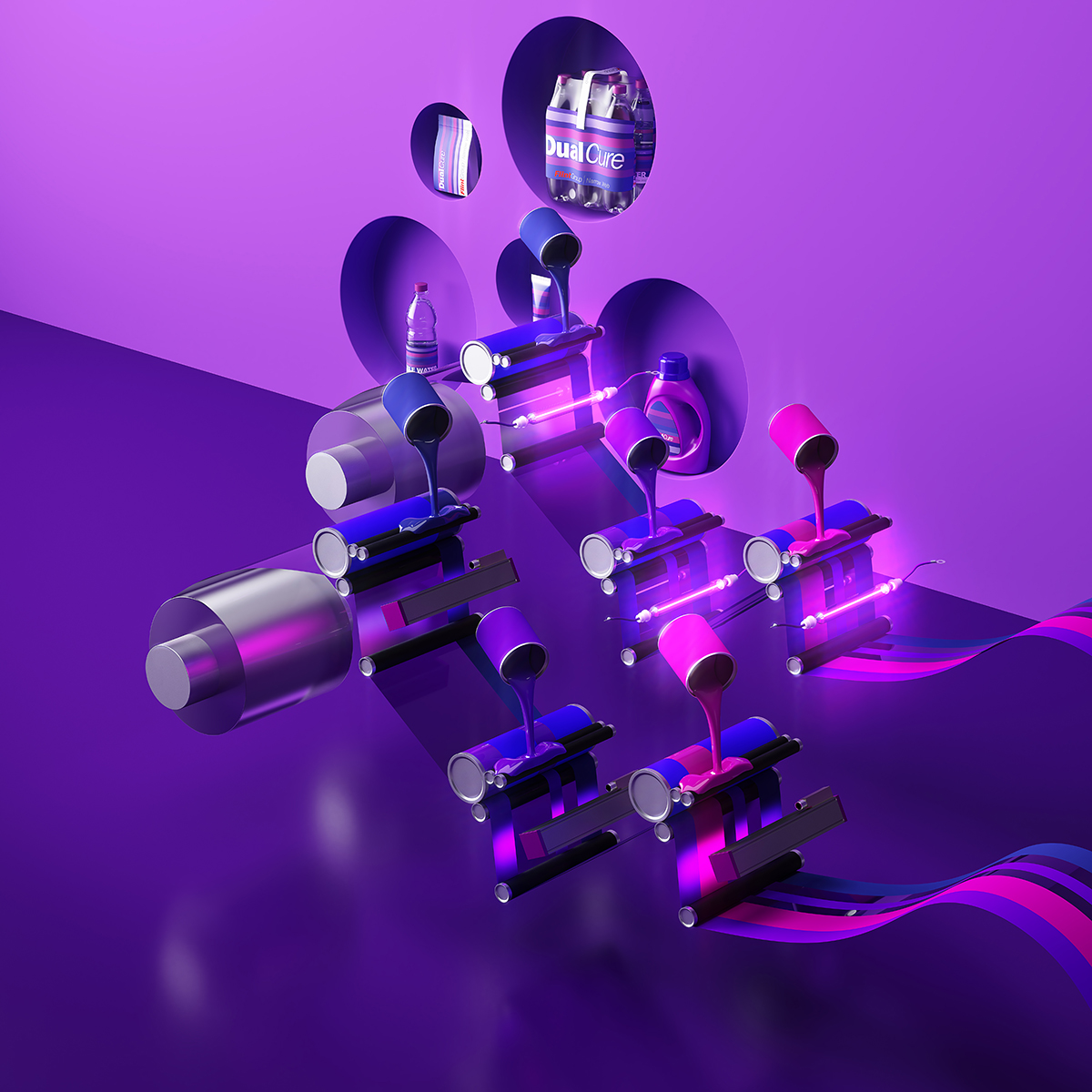

To support customers in this transition, Flint Group designed its EkoCure® range of inks with Dual Cure technology. These inks provide superb performance with both traditional lamps and UV LED curing. In addition, this range includes EkoCure ANCORA F2, designed for stringent food labelling and packaging applications. With EkoCure’s dual curing capabilities, printers can transition unit by unit or press by press.

Olsson continued: “With EkoCure, and its ability to cure under mercury or UV LED lamps, we are helping our customers futureproof their operations. As the case for LED curing grows, no printer wants to generate unnecessary waste or be stuck with costly UV ink inventory they can’t use as they transition over. With over ten years of experience formulating LED inks, Flint Group is the market leader in this technology with the expertise to make the switch easy and cost-effective for our customers.”

“LED technology today is miles ahead of where it was a decade ago and can finally meet its potential, offering speed, quality, and consistency indistinguishable from traditional UV curing but with additional cost and environmental benefits. From our perspective, it’s the future of narrow web printing. With our pioneering EkoCure range and local technical expertise, we are perfectly positioned to support our customers to adopt LED curing easily.”

For more information, visit www.flintgrp.com.