LaserSpeed Pro Enables Converters to Accurately, Reliably Control Web Tension and Realize Value

- Published: May 10, 2021

The BETA LaserMike LaserSpeed® Pro gauge from NDC Technologies enables paper, film and foil converters to reliably control web tension by accurately measuring the length and speed of products during production.

The BETA LaserMike LaserSpeed® Pro gauge from NDC Technologies enables paper, film and foil converters to reliably control web tension by accurately measuring the length and speed of products during production.

Most manufacturers depend on the accuracy of its drive speeds or contact encoders, such as mechanical tachometers. Products typically exhibit a certain amount of slippage on the drive roller based on texture, product composition or tension at other points on the line. A contact encoder attached to the drive roller exhibits the same problem.

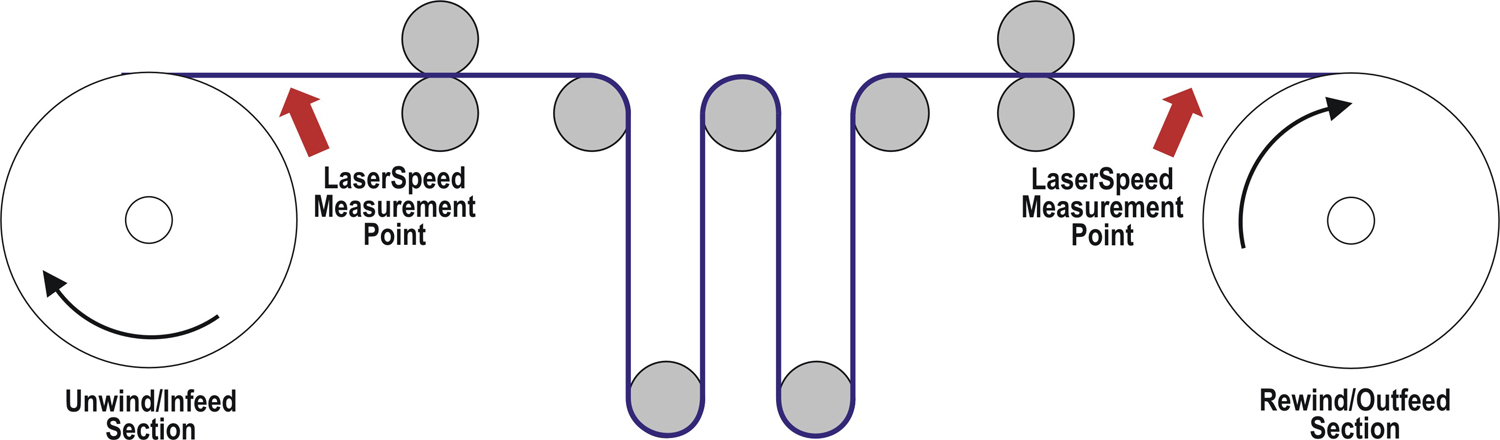

The LaserSpeed Pro laser encoder reportedly solves this problem by directly measuring the product speed of the web without making contact. Placing a LaserSpeed Pro encoder at each critical measurement point along the line enables converters to accurately measure the web speed and determine the amount of tension of the product.

The LaserSpeed Pro projects a unique pattern on the surface of the product moving on the web, which is then reflected back to the unit and translated into speed. Pulses are generated at a rate proportional to the speed. The pulse output is sent to a control system to indicate length and trigger process actions.

An ultra-fast processing engine reportedly enables length and speed measurements to be made up to 100,000 times per second and pulses can be driven up to 5 MHz to control process actions.

LaserSpeed Pro tracks the most minute product movements back-and-forth, even at rapid acceleration/deceleration rates, and can measure down to true zero speed. Additionally, this gauge eliminates the need for continual checks of accuracy and constant tweaking of the control system.

The result is significant cost savings by delivering precise and repeatable measurements day-in and day-out, from production run to production, reducing product waste and give-away. LaserSpeed Pro also reportedly offers communications flexibility consistent with Industry 4.0 and can be easily integrated into production networks for real-time data exchanges and tight processing efficiencies to drive product quality.

A European certified length measurement system is also available that meets MID (Measuring Instruments Directive) requirements.

For more information, visit https://www.ndc.com.