Microsoft’s HoloLens Technology Emerges as a Critical Tool for Converting Machine Owners

- Published: December 16, 2020

Contributed by Delta ModTech

The use of HoloLens technology has proven to be effective at streamlining and improving everything from factory acceptance testing to servicing. As Delta ModTech increases its use of this mixed reality tool, you get the sense that we are only scratching the surface of its potential.

COVID-19 has disrupted our world in staggering ways. But for manufacturers, it’s merely accelerated trends such as digitalization. Nowhere have we found this more apparent than in our own adoption of mixed reality HoloLens technology from Microsoft.

What used to be the stuff of science fiction movies like Minority Report has become interwoven into our daily lives. It’s already caused a seismic shift in Delta ModTech’s entire approach, and it is producing significant time- and cost-savings in the process.

What is HoloLens Technology?

Microsoft HoloLens is a pair of mixed reality smart glasses. It allows a wearer to superimpose a desktop environment over a real-world object, such as a piece converting machinery, and make notes, annotations, or view instructional videos, all in a mixed reality view. Its head-mounted display allows users to touch, grab and move holograms in a way that feels natural, as if they were responding to real objects.

The Difference Between “Mixed Reality” and Augmented Reality

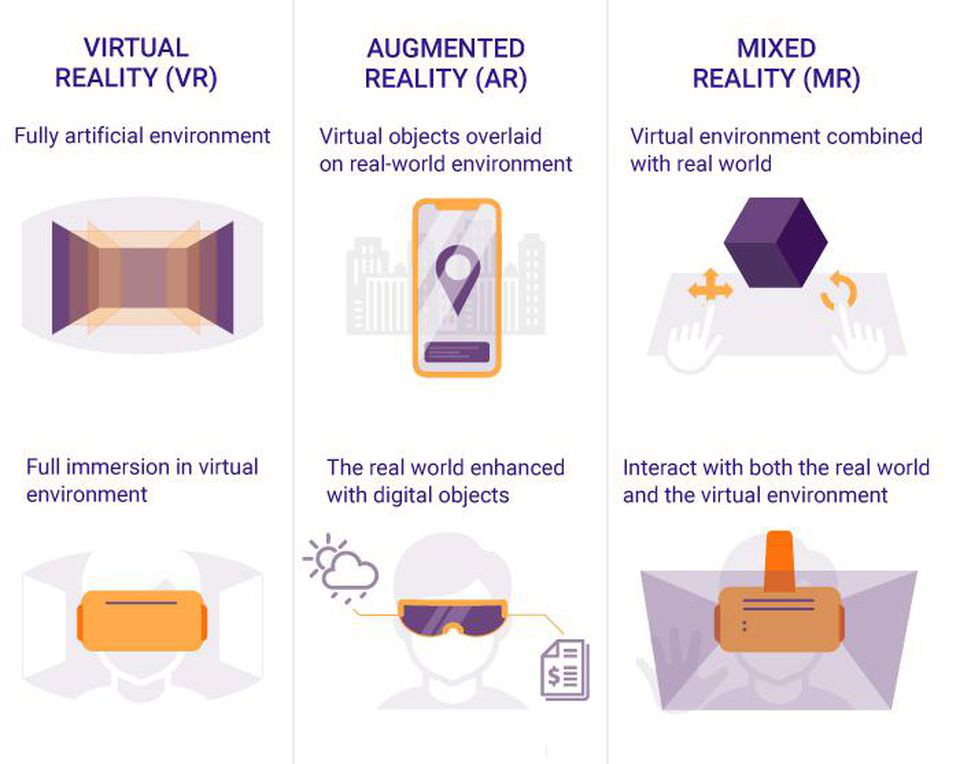

Augmented reality (AR) is defined by virtual objects overlaid on a real-world environment. You might see how a digitally created object, like a couch, looks in your living room.

With mixed reality (MR), you start with the real world, and then add digital content to it. In this case, it starts with Delta ModTech machinery, and add videos, notes, and other forms of digital content to the shared environment.

This graphic nicely illustrates the differences between the “realities.” (Source: Forbes)

Utilizing HoloLens Technology

The first time Delta ModTech had used the technology was on a remote FAT. After first experimenting with FaceTime on an iPhone, Delta and the customer switched to the HoloLens. The customer was so impressed with the functionality that, “By the end of the week, they had purchased a pair, and one for their sister plant,” said Ryan Herman, electrical engineer at Delta ModTech.

Delta ModTech has deployed the technology on a pilot basis with a number of customers for all phases of manufacturing converting machines, and is primarily using the technology in a number of ways:

Factory Acceptance Testing (FAT): We conduct FATs at our manufacturing facility, and use HoloLens so the customers can participate remotely.

Training: We can conduct live demonstrations for operators.

Service: We can troubleshoot by seeing exactly what the operator is seeing.

Two specific HoloLens features have been used extensively:

- Recording video while demonstrating.While wearing the HoloLens, video recording can be started while showing operators how to set up a die. “If we go through a training session, we’ll have a video of everything we just taught them,” Herman said.

With customized equipment, this not only allows for machine-specific training, but the live nature of the recording allows for customer questions to be recorded.

- Annotating pictures. HoloLens allows the operators to take a picture of what they’re seeing, and share it with Delta ModTech.

The Delta ModTech team can then annotate the photo — make notes, draw circles on it, insert arrows — to explain how to address a problem. The operator can then go back to the machine and “pin” the annotated photo above the machine, and follow the instructions.

Re-engineering Machines to Maximize the Use of Tools Like HoloLens Technology

Expecting HoloLens alone to improve efficiency is missing the forest for the trees. You need to start the process by creating machines that allow for easy use and servicing in the first place. To that end, Delta ModTech has restructured how their equipment is built. Grenwis points out recent approaches to wiring that simplifies solving potential services issues. For example, a machine might have had fifteen different wires with different connections, and if it had to be moved, fifteen wires would need to be rewired. Now the wires all fit into centralized quick disconnects. “It’s much easier for our technicians to say, ‘These are the wires you need to unplug.’ ” Grenwis said.

Improving an Already Successful Process

A foundation of Delta ModTech’s approach is making our technical and engineering staff available to our customers. HoloLens’ unique features allow us to extend this access in a number of unique ways.

While HoloLens is a game-changer in terms of technology, it’s part of an ongoing process to deliver a great depth and breadth of service. “It’s simply a new tool in the tool box,” Herman said.