Brown Machine Group Announces Industry-Leading C-RUSH System for Reducing Manual Labor and Increased Productivity in Paper Cup Manufacturing

- Published: October 09, 2020

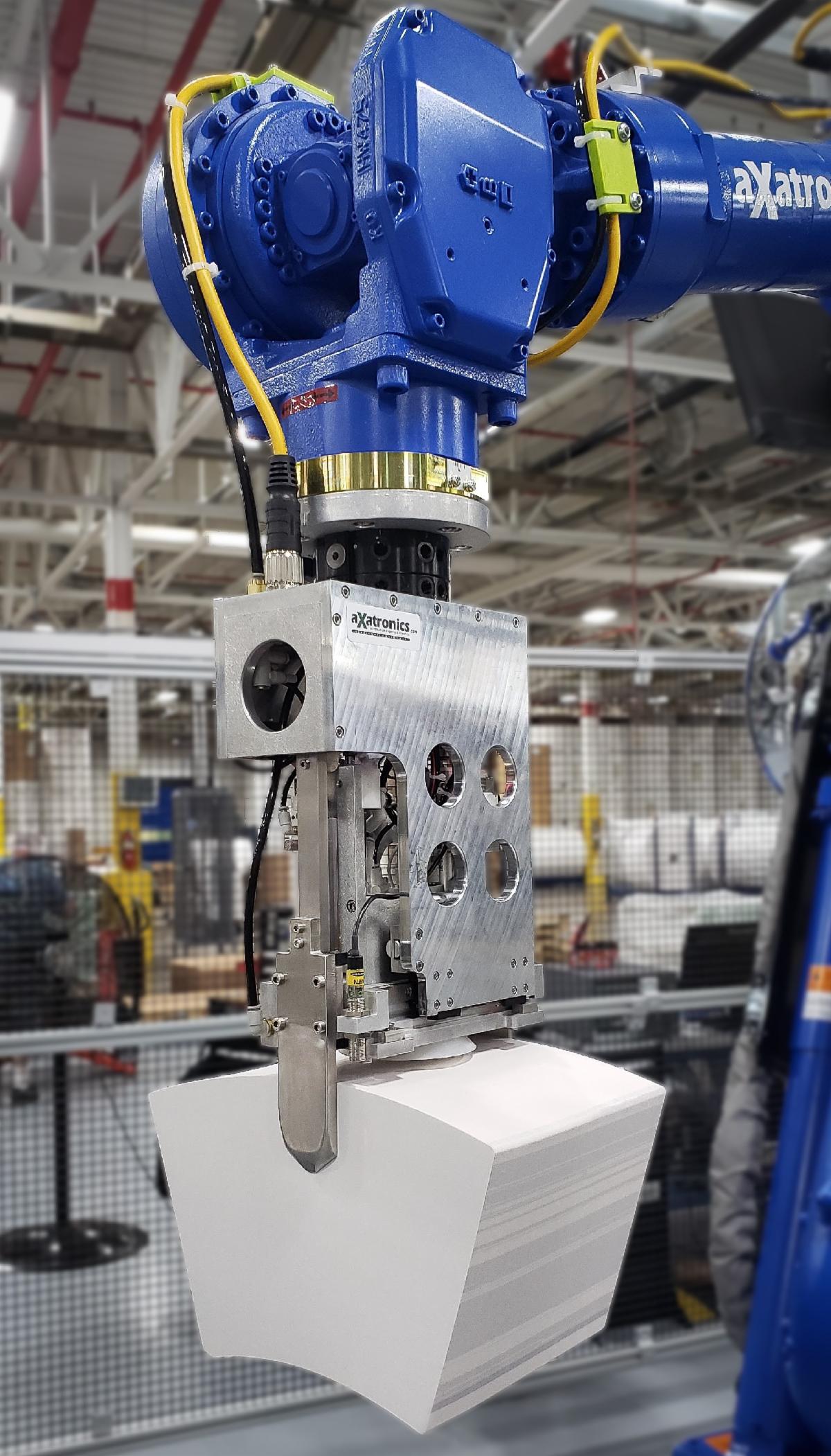

B rown Machine Group (BMG) announced the aXatronics C-RUSH System, the first of its kind to automatically remove sidewalls, or blanks, from high-speed, vertical die-cutters and robotically place them into work-in-progress containers.

rown Machine Group (BMG) announced the aXatronics C-RUSH System, the first of its kind to automatically remove sidewalls, or blanks, from high-speed, vertical die-cutters and robotically place them into work-in-progress containers.

C-RUSH is reportedly equipped with SMART-DOLA™, a new patent pending die-cutter output lane assembly (DOLA) fixture that dramatically improves overall system throughput.

Designed by aXatronics and manufactured in the Nalle Automation Systems (NAS) facility, C-RUSH allows the operator to interface with the die-cutter by pausing and resuming the robotic pick and place automation. No robotic experience or a high level of training is required to operate the system.

Designed for 24/7 operation, C-RUSH makes die-cutters more productive by reducing die-cutter downtime or production slowdown due to personnel fatigue. It could handle up to two million 21-ounce sidewalls per day.

A single uniquely designed robotic end-of-arm-tool (EOAT) reportedly handles cup sizes from 12 to 30 ounces, automatically unloading a multilane DOLA before placing each stack of sidewalls into a tote. Lane handling and stacking configuration includes interleaving tier sheets and stacking patterns engineered to each cup’s specifications, and the C-RUSH System automatically changes its configuration with no operator intervention when changing dies.

The SMART-DOLA contains all pertinent ‘recipe’ data for the specific size and shape of the sidewall it is designed to handle. This recipe data is automatically uploaded into the robot controller whenever the fixture is mounted onto the die-cutter. Using laser distance measuring sensors, the SMART-DOLA can automatically slow down the die-cutter before it becomes full.

Operator safeguards provide CAT 3 safety with fencing and personnel laser-based area sensors. Other features include automatic recovery after error conditions and acknowledge of an E-STOP. In addition, the conveyor system is designed with automated guided vehicle (AGV) capabilities.

For more information, visit https://brownmachinegroup.com.