Constantia Flexibles Introduces Quality Tests

- Published: March 15, 2016

BLYTHEWOOD, SC | Constantia Flexibles, a global corporation that develops, manufactures, and supplies flexible packaging solutions for the pharmaceutical, healthcare, home and personal care, food and beverage markets, has introduced the Live Stress Check for its Coldform pharmaceutical packaging solution.

The Live Stress Check tool determines the strain level applied to coldform foil and the quality of the forming process when running on blister lines. Results are used to optimize the manufacturing process by uncovering improvements that can be made concerning forming plug designs, plug materials, and process setup.

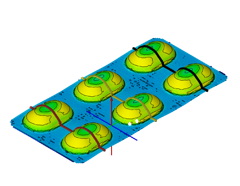

To perform the stress check, a pattern of high-resolution dots is printed on the Coldform laminate which, when stretched, changes. The Live Stress Check sample, with cavities formed under production conditions, is inspected with a camera system and special software to determine these distortions. Then an automatically generated 3D-image illustrates the degree of strain at various areas of the blister, information that reportedly allows for significant improvements to both the overall process and the cavity shaping steps in particular.

A related service offered by company is a simulation of the so-called cross-permeation in coldform blister packs. This concerns the moisture that permeates into a blister cavity in very small quantities along the inner layers of the blister’s punched edge (moisture permeation is only possible along the punched edge, because the base foil’s aluminum creates a 100% barrier against water and oxygen).

Such cross-permeation can be controlled using laminates whose plastic layers provide a higher barrier to water vapor on the coldform laminate’s inside layer. For example, polyvinyl chloride films can be substituted by polypropylene films for added protection. Cross-permeation also can be influenced by the blister’s design; often, correcting this sort of systemic flaw involves adjusting the sealing area or eliminating blister perforations altogether.

The simulation assesses the effect of using various plastics and/or making design changes to address cross-permeation. Company says the early-stage test can improve product shelf life while avoiding expensive mid-process reiterations. The result is said to be increased speed to market, reduced materials waste, and an uptick in overall productivity.

This email address is being protected from spambots. You need JavaScript enabled to view it.