TRESU Launches Doctor Blades, Ink Supply System

- Published: June 13, 2013

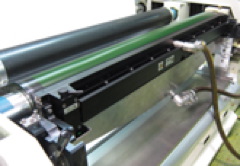

KOLDING, DENMARK | TRESU Group, a global supplier of flexo printing lines and ancillary products, introduced a range of chambered doctor blade systems and a new ink circulation system at the recent China Print 2013.

The doctor blades are said to ensure a uniform, smooth, splash-free, and uncontaminated laydown of flexographic inks and coatings in the anilox roll cells, preventing microfoaming and blistering. Together with the ink circulation systems, they are also said to enable accurate pressure, flow, and viscosity control, efficient temperature regulation and cleaning, fast blade changeover, and airtight sealing of the chamber. The systems are suited to printing speeds to 500 mpm and cover all narrow and mid-web flexo printing and coating applications.

Patented rubber Seal System forms an airtight closure at the chamber sides, eliminating leakage. The airtight environment ensures leftover ink can be stored for long periods without evaporation or perishing, company says. The chambers feature company’s E-Line doctor blade-changing system, enabling blades to be slotted into position and released safely within one minute by a clamp.

The new F10 iCon ink supply system features company’s patented viscosity and flow control, as well as temperature control over the ink as it circulates from ink bucket to anilox roller. Reportedly, this keeps the ink at constant viscosity to ensure stable ink density on the printed substrate and constant pressure and flow to stop air mixing with ink in the anilox chamber, in turn preventing blistering and ink starvation. Airtight environment allows safe handling and storage of solvent inks in environments where solvent evaporations are likely.

This email address is being protected from spambots. You need JavaScript enabled to view it.