Holography | Industry Developments Give Packagers an Edge

- Published: February 13, 2014, By Ian Lancaster

Advances in film coating and manufacturing open the door for innovative use of holographic materials

H olography plays an important role in packaging as manufacturers face the challenge of capturing customer attention by giving products a highly distinctive decorative edge over competitors. Here are highlights of some of the latest award-winning industry developments that can give packaging producers an edge.

olography plays an important role in packaging as manufacturers face the challenge of capturing customer attention by giving products a highly distinctive decorative edge over competitors. Here are highlights of some of the latest award-winning industry developments that can give packaging producers an edge.

Continuing advances in film coating and manufacturing technology have opened the door for ever more innovative opportunities for embossed holographic materials for use in packaging, while a wide variety of specialist origination techniques offer an infinite variety of colorful 3D visual effects, ranging from the bright and stunning to more subtle graphic features. Holographic films in particular are ideal for a wide variety of flexible eye-catching applications, further increasing the graphic opportunities available, reinforcing brand identities, capturing customer attention, and bringing new life to mature or aging pack design.

Indeed, holography’s ability to push the boundaries for new packaging applications continues, reinforced by the recent holography industry awards, which saw imaginative solutions reinforcing the important role the technology plays, particularly in tackling product anti-counterfeiting and authentication.

For example, Hazen Paper Co., Holyoke, MA, has created an award-winning (IHMA’s Excellence In Holography Awards 2013) package featuring custom holography on its Envirofoil transfer metallized lamination, designed to catch the eye of customers browsing retail and supermarket shelves. Unlike full-spectrum holography, this next-generation "white-motion" holography can be adopted to enhance packaging through a range of interesting, dynamic, and visually stimulating designs without compromising the prismatic integrity of corporate or brand colors.

For example, Hazen Paper Co., Holyoke, MA, has created an award-winning (IHMA’s Excellence In Holography Awards 2013) package featuring custom holography on its Envirofoil transfer metallized lamination, designed to catch the eye of customers browsing retail and supermarket shelves. Unlike full-spectrum holography, this next-generation "white-motion" holography can be adopted to enhance packaging through a range of interesting, dynamic, and visually stimulating designs without compromising the prismatic integrity of corporate or brand colors.

Envirofoil contains no plastic and a minimal amount of aluminum—so it can be recycled as easily as printed paper—while striking source reduction means it carries 20 times less metal per square inch than metallic ink and can be printed offset or with digital inks. It meets strict environmental criteria, certified by the Forest Stewardship Council, Sustainable Forestry Initiative, and the international Programme for the Endorsement of Forest Certification.

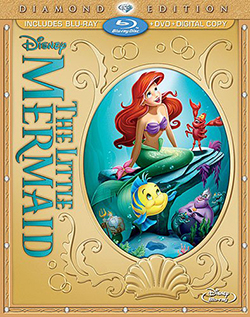

A DVD cover sleeve for The Little Mermaid produced by Agi-Shorewood, Metal Magic, and Hazen has also garnered high praise—the foil board is coated with a high-definition gloss and has an offline sculpted embossing that creates texture and adds shine to the package. The glossy and embossed title and artwork provide dimensions to the package without overcompensating for the art, while a hologram special effect that mimics a "water glare" over the entire cover of the o-sleeve provides a feature designed to catch the eye of the customer.

NovaVision Inc., Vacumet Corp., and Angell-Demmel North America’s Nissan LEAF holographic kick plate was the overall category winner with the two other applications commended.

Hologram manufacturers Optaglio’s dip into the past has created one of the most imaginative hologram designs of recent times, which offers big potential for use in dynamic packaging applications for suppliers of products looking for that something extra to attract the interest of time-pressed retail customers. The "La Belle Époque" hologram eschews modern design to create a vintage art nouveau style that has led to the company winning a top industry award for one of the most original designs of the last 12 months. Using a combination of 2D/3D background, kinetic effects, and masked lenses to create a sense of depth and style, microtext, nanotext, nanographic and advanced CLR imagery are also features of the hologram.

Hologram manufacturers Optaglio’s dip into the past has created one of the most imaginative hologram designs of recent times, which offers big potential for use in dynamic packaging applications for suppliers of products looking for that something extra to attract the interest of time-pressed retail customers. The "La Belle Époque" hologram eschews modern design to create a vintage art nouveau style that has led to the company winning a top industry award for one of the most original designs of the last 12 months. Using a combination of 2D/3D background, kinetic effects, and masked lenses to create a sense of depth and style, microtext, nanotext, nanographic and advanced CLR imagery are also features of the hologram.

Holostik India Ltd.’s technique for using low optical density (OD) metallizing on holographic embossing without touching the sealing side of PVC also has big potential, particularly for pharmaceutical packaging applications. It enables blister packs to be produced with the hologram on the blister side. This advanced hologram for blister packaging can save time and money in production as it does not require changes to the set up of existing packaging machines. Metallizing also enhances the barrier property of PVC blister film while a high temperature scratch proof coating on the hologram, which can be transparent or colored, also was praised for its technical excellence.

New imaging techniques and combinations of other overt authentication technologies with holograms are producing advanced optical security devices, which combine ease of recognition benefits with significantly enhanced resistance to counterfeits, enabling products to be controlled through an expanded system solution involving security authentication features, tracking mechanisms, and investigative services. So with the seemingly remorseless march of technology, there’s no reason why the hologram will not continue to evolve as packaging designers continue to see the benefits unfold before their eyes and comfortable with a technology that has a lot to offer.

Ian Lancaster is general secretary of the International Hologram Mfrs. Assn., Sunbury, UK.The IHMA is made up of more than 80 of the world's leading hologram companies. Its members are the leading producers and converters of holograms for banknote security, anti-counterfeiting, brand protection, packaging, graphics, and other commercial applications around the world.