Labels | Market Update on IML & Sleeve Technologies

- Published: June 04, 2013

Two relatively recent extensions to the world’s portfolio of packaging technologies were the subject of back-to-back events in Amsterdam recently, hosted by AWA Alexander Watson Associates: in-mold labeling and sleeve labeling.

In-Mold Technologies Seminar

The 2013 In-mold Technologies Seminar represented an opportunity for professionals to receive a one-day update on a packaging format for plastic containers that is beginning to take market share around the globe, particularly for high-volume containers for prime labels for fats, ice creams, and yogurts. Specialist market researchers AWA Alexander Watson Associates are tracking its progress; and VP/Senior Consultant Dr. William Llewellyn opened the program with an update.

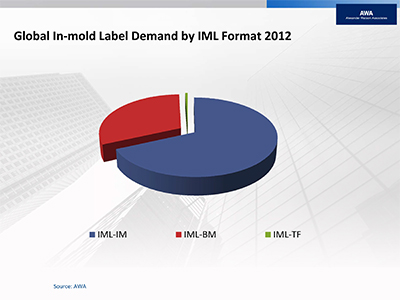

Three technologies are currently employed—injection molding, extrusion blow molding, and—newly emerging—thermoforming. Globally, he showed, most activity is in injection molding, with the Asia Pacific region growing fastest; and in the medium term, the market is forecast in the medium term at 2.2%.

Lively panel discussion looks to the future

AWA’s President/CEO Corey M. Reardon moderated a lively panel discussion on label materials, featuring spokesmen from leading cross-disciplinary industry participants. Comments of significance included, from Andre Soterio, Yupo, that east European growth is compensating for west European stagnation; and that generic plastic containers, which can carry any available decoration technology, are turning to in-mold (Rudi Verhulst, Drukkerij Verstraete), particularly for high-volume new products (Joerg Hofmann, Innovia Films).

Michael Demchinski, Taghleef Industries, suggested that thin-walled containers could go as low as 40-50 micron in thickness, but that emerging economies, where there is no experience of in-mold, would be obliged to start with higher calipers. Participants agreed that the technology could take off in a big way if a platform of advanced films with capabilities such as moisture-resistance and barrier properties become available.

Print developments

Moving into the realms of the practicalities, Amanda Jones of Paragon Inks examined all the ink-related issues, from "everyone wants everything for nothing!" to the ideal formulas for flexo inks and coatings for IML; legislative influences; and cures for common problems. Label business consultant Hans Poortinga showed how a label printer’s offering could be expanded with all technologies—both conventional and digital. "Going IML won’t double your turnover," he observed, "but it will keep your existing business alive and healthy!"

Digital print for labels on plastic containers was the precise topic addressed by Filip Weymans of Xeikon, whose company offers a comprehensive portfolio of CTP imaging equipment, color printing presses, and pre- and post-press support and is today offering a digital solution for experienced sheetfed in-mold labels, which is already running in two installations.

Victor Gomez of Durst dealt in the opportunities presented by narrow-web color inkjet print for in-mold labels—possible in CMYK and white and metallic inks, and now competitive with flexo at the 50,000 label point.

Hardware developments

José Peña of Husky Injection Molding Systems showed how the company delivers tailored solutions for in-mold packaging in terms of machines, molds, hot runners, and robots, as well as "full system integration" for customers. Dr. Hartmut Traut from Trexel introduced the company’s microcellular MuCell injection molding technology, which can deliver significant weight reductions in containers, while Hubert Kittelmann from Marbach gave an update on the technology features of T-IML, the innovative thermoforming process.

This particular solution also was analyzed in depth by Claus Weinert of Illig, who pronounced it to be "now really competitive." The trend to larger machine sizes, featuring a higher number of cavities, is a business focus today for machine suppliers Netstal, whose hybrid machines, said Thomas Iten, are delivering energy efficiency coupled with the highest injection performance.

Platinum sponsors Paragon Inks and gold sponsors Illig, Taghleef Industries, Yupo, and Xeikon, joined seminar delegates for cocktails after the seminar. Looking ahead in the AWA events calendar, the annual IMLCON and IMDCON conference for 2014 will take place in Phoenix, AZ, Feb. 19-20, 2014.

Sleeve labels – shrink and stretch

Sleeve labels became the agenda the following morning, when nearly 100 delegates convened for the AWA International Sleeve Label Conference and Exhibition 2013. The maturing stretch and shrink sleeving processes now represent a complex base of technologies, which were examined in depth in all aspects over the one-and-a-half-day program.

Market profile

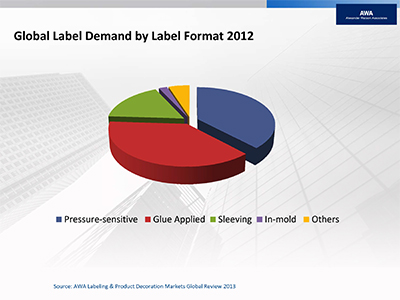

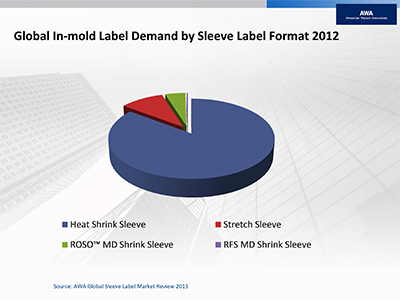

AWA’s Llewellyn set the context with current market data, showing how, with about 17% of the total global label market today, sleeve labels’ CAGR for the medium term is now a projected ± 5%. This is slower than hitherto, but still ahead of other label technology growth rates. Growth continues to be driven by heat shrink sleeves (with roll-fed machine-direction shrink sleeves showing potential in North and South America); and high-shrink films, offering 80%–85% shrinkage, are now making their appearance available on the market.

In a marketplace characterized by films, understanding and managing plastic raw materials pricing volatility is critical, as Philip Karig of specialist consultants Mathelin Bay Associates LLC showed. It is essential to incorporate volatility into the materials selection process because, he said, "It is here to stay!"

Sleeves have gained a high profile in the branding arena, delivering exceptional shelf "stand out" for many products, as Rob Vermeulen of Vermeulen Brand Design, and Simon Preece of Elmwood Design testified. This would not have been possible without the technological contributions of the label producers, and Kris Van Bael of Esko showed how the company’s software solutions are delivering real advances in shrink label artwork origination—including 3D product imaging of the label design on the product which, he says, also helps by "speeding a new label to market."

Inks are a key part of the label package, and Colin Smith of SunChemical introduced the broad platform across which the company delivers eye-catching innovation.

Materials for shrink sleeves

Shrink sleeve label design is also very dependent on choosing the right material; and Chris Frank of film producers Klöckner Pentaplast set out the key selection criteria across the current options— PVC ("the preferred substrate in all regions," he said), OPS, PETG, micro-voided PETG, PLA, and Co-ex. In parallel, Paul Marquard of Taghleef Industries discussed the company’s new generation of OPP roll-fed shrink films.

Roll-fed shrink films are, according to Raffaele Pace of Sidel, "the future of the shrink sleeve market," and he demonstrated the company’s roll-fed application machinery in action in liquid packaging/beverage applications.

Applying shrink sleeves to empty, rather than pre-filled, containers is a special challenge for which Laurent Corbet of Karlville Development, manufacturers of converting and application equipment, presented a technical reference paper. The benefits of another sleeving technology, high-shrink machine-direction roll-on-shrink-on labels, were highlighted in a paper on Polyphane Fit solutions from Rony Ben-Shoshan of Polysack Flexible Packaging.

Tony Couling of Accraply, following an evaluation of the implications of film downgauging, summed up the overarching conference message on shrink sleeves: "Always involve your sleeve material supplier, printer, converter, container and machinery supplier right from the beginning of the project. A successful shrink sleeve project depends on everyone!"

This message was echoed by Will Schretzman of Verst Group Logistics, who offer wide-ranging options in the sleeving arena for contract packaging and related services, and who are currently developing the technology and market for high-elasticity stretch sleeves.

Materials for stretch sleeves

Moving the focus from shrink to stretch sleeves, Dr. Kurt Brunner of Dow Europe along with Thomas Galatik of Petroplast Vinora, full-service flexible packaging films, printing, and finishing suppliers, introduced new polyolefin-based Visique stretch sleeves and the opportunities for premium on-pack aesthetics, functional features, and a cost/sustainability profile that they offer for highly contoured bottles and containers.

Wolfgang Ploesch of CCL Label presented the company’s answer in this arena—high-shrink TripleS films for large-area bottle decoration—which is claimed to offer cost and energy savings and easy recycling.

Environmental concerns

No discussion of plastics-based technologies would be complete without consideration of end-of-life reuse and recycling, and this subject recurred throughout the conference program. Stuart Foster, CEO of not-for-profit Recoup, which represent the UK in EPRO, the European Association of Plastics Recycling and Recovery Organisation, outlined the role of sleeves and labels in plastics packaging recycling, and Kevin Frydryk of ExxonMobil Chemical delved in detail into the options, including label separation by flotation, and existing and developing standards.

Lively discussion around the associated exhibition, featuring leading suppliers, continued throughout the conference breaks and the cocktail reception on the first evening, offered by platinum conference sponsors Accraply, Dow, Paragon Inks, and Petroplast Vinora. Comments conference moderator Llewellyn: "AWA has been following developments in this particular market now for several years, and our annual conference, alternating between Europe and North America, always delivers an outstanding agenda and the attendance of knowledgeable professionals who want to keep abreast of what’s new and network with their industry peers."