HOW TO: Identify What Perforation Method is Right for Your Application

There are HOLES in many more places, performing important tasks than most of us realize. Papers, films, foils, foams, cardboards, nonwovens, composites and other materials can all be MACRO, MICRO or NANO PERFORATED for a wide range of reasons.

There are HOLES in many more places, performing important tasks than most of us realize. Papers, films, foils, foams, cardboards, nonwovens, composites and other materials can all be MACRO, MICRO or NANO PERFORATED for a wide range of reasons.

There are obvious applications, like the holes that allow air in bags to extend shelf life. But, how about giving diapers sufficient porosity to allow urine though to an absorbent layer? A large open area to allow fragrance to emit from an air freshener? De-gassing during a rubber vulcanizing process, or to allow air to escape between the layers of an aircraft’s composite layered fuselage to increase structural rigidity? In food packaging, the most common applications are packaging for pet foods, frozen foods, boil in bag, microwaveable packaging, lidding films, steam vents and easy tear openings. The applications are vast and endless.

How do I Know What Perforating Technique Will Work Best for my Project?

This question is literally the reason why we have become a one-stop shop for perforating solutions. We take the following simple steps to take you from concept to production:

- Discuss the project and expected outcome

- Study material and see which process works best to achieve your perforating goals

- Determine hole size and pattern that is suitable

- Run samples

- Design tooling and machinery

- Run toll perforating or

- Install and setup perforation tooling or machinery in your facility.

Whether you are having issues with trapped air or liquid, looking to add grip, texture, extend the surface area of a material for increased absorbency of liquid or sound, our experience in the hole making arena will fast track you to where you need to be.

Perforating Technologies Available:

Perforating Technologies Available:

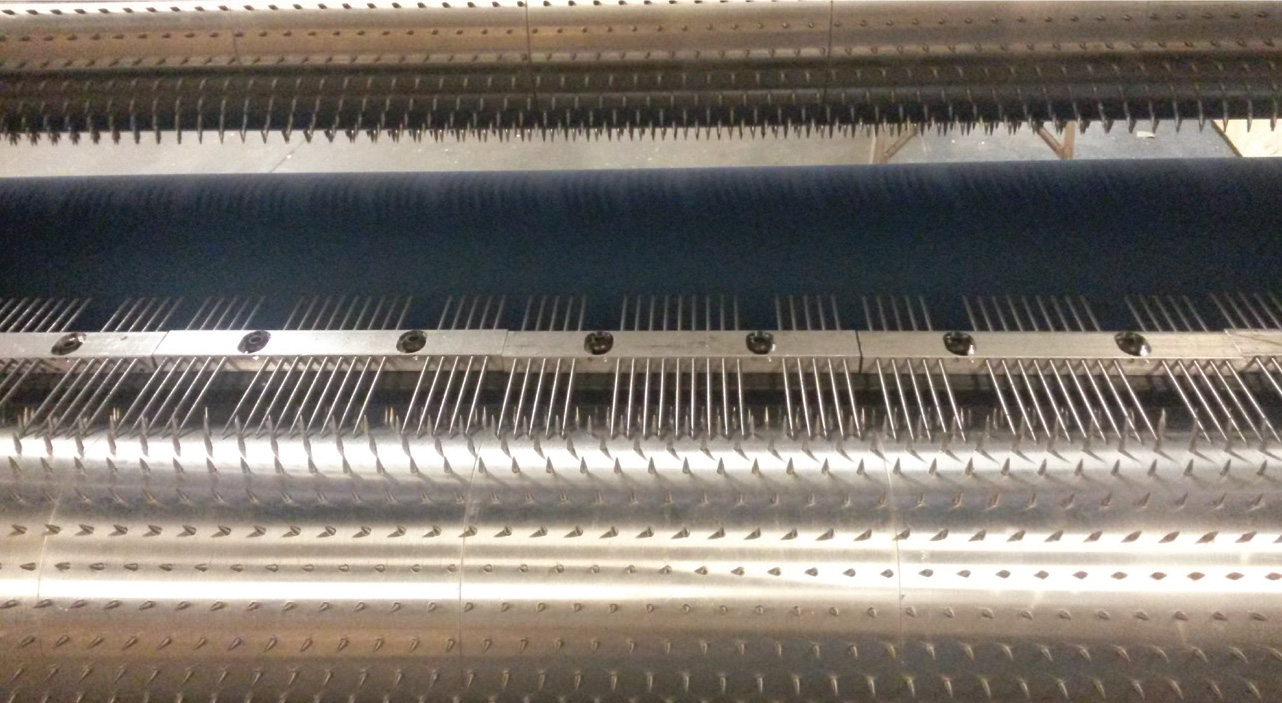

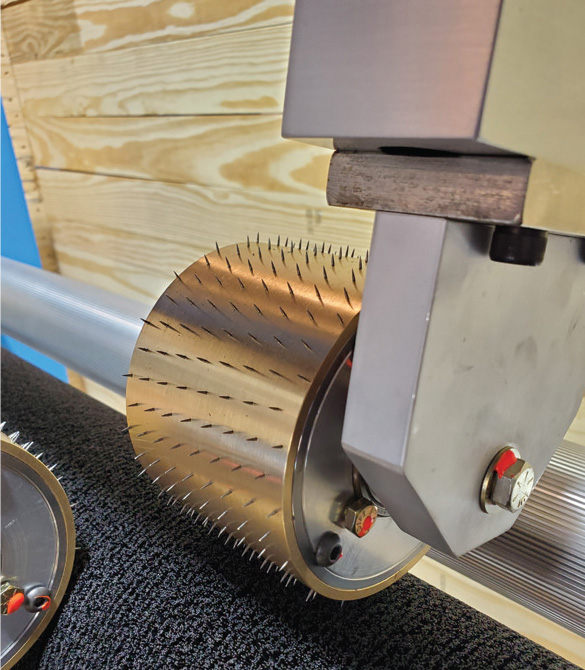

- Hot pin perforating (rotary and vertical);

- Cold pin perforating (rotary and vertical);

- Slit perforating (razor and crush);

- Tear line perforating (cross tear, inline tear, both or custom);

- Punch perforating (vertical cam, electro-pneumatic and electro-mechanical);

- Rotary punch perforating (ejection and suction);

- Laser perforating;

- Thermal (flame) perforating;

- Vacuum perforating; and

- Embossing.

No matter whether you have an extruder, laminator, flexo-printer, coating machine, slitter, center folder, VFFS, HFFS, flow wrapper, bag making machinery or other process, perforating can be added to your existing equipment as tooling, as an attachable unit, or can be offered as an offline process. We have easy to complete RFQ sheets and detailed information about each process available on our website, and our knowledgeable sales team is here to answer any questions you may have.

Save time. Save money. Add value. Call the hole making experts for the “hole solution”.

Finzer Roller

This email address is being protected from spambots. You need JavaScript enabled to view it.