COVER: Testing, Inspection & Quality Control

- Published: May 24, 2021

Ensuring Accurate, High-Quality Codes on Flexible Film

By Andy Gray, Marketing Manager for thermal transfer overprinting solutions at Markem-Imaje

Often the last element added to items, codes are a vital part of the product journey. Typical data includes batch numbers and expiry dates but can extend to variable information such as QR codes, ingredient lists and barcodes. Increased expectations in terms of traceability and digitalization are fueling an increase in complexity. In food and beverage alone, code length is likely to double from 30 to 60 characters.

Often the last element added to items, codes are a vital part of the product journey. Typical data includes batch numbers and expiry dates but can extend to variable information such as QR codes, ingredient lists and barcodes. Increased expectations in terms of traceability and digitalization are fueling an increase in complexity. In food and beverage alone, code length is likely to double from 30 to 60 characters.

Illegible, missing, or incorrect codes can cause modern supply chains to break, with significant financial and reputational costs, e.g., retailer or wholesaler fines and slow, unnecessarily large recalls. It is imperative therefore that manufacturers choose the technology offering the optimal balance of quality and performance versus cost.

Mechanical methods left behind by digital

Although used extensively for years, mechanical coding has many disadvantages.

Used in batch processes, hot stamping applies codes with a metal stamp held in a heated block. It is inflexible as the stamps are static and must be changed before each new job, making it ripe for human error. Also, as manufacturers use ever-thinner films, worn or broken stamps can perforate films, causing waste.

Rotary coders, used in continuous processes, pick up ink from a tray and transfer it to products. As the ink in the roller runs low, print quality is reduced, often such that it becomes hard to see. Additionally, rotary coders work on a fixed pitch, sometimes making it difficult to accurately apply a code. They are also susceptible to operator mistakes.

Neither are suitable for printing barcodes, ingredient lists and real-time information. Digital technologies accommodate these easily, with many more characters. Codes can often be updated without even stopping production.

Thousands of messages can be stored within the printers themselves, transferred by operators using USB sticks or automatically sent to networked coders via suitable software pulling the data directly from company databases to ensure codes are 100% correct and compliant, while accelerating production start-ups. The printed data can even be sent back to the databases giving companies real-time inventory visibility.

Which digital method is best?

There are four principal options – laser, continuous inkjet (CIJ), thermal inkjet (TIJ) and thermal transfer overprinting (TTO). TTO is the only one specifically for flexible film.

There are four principal options – laser, continuous inkjet (CIJ), thermal inkjet (TIJ) and thermal transfer overprinting (TTO). TTO is the only one specifically for flexible film.

As with most things, the choice depends on the situation.

Any method producing 300 dpi is considered to match the quality of pre-printed designs. Theoretically, the best code will be produced by a TIJ working at low speed. However, as TIJ is a non-contact technology, any line vibrations can cause small print distortions. Also, as speed increases, the quality gradually deteriorates until TIJ can be matched by the other methods.

TTO and laser are the best for 300 dpi prints on medium to high-speed lines, respectively. However, laser cannot be used on all materials. If 70 dpi is acceptable, then CIJ is also suitable for fast lines as it prints on any surface at all available conveyor speeds. Some CIJ heads achieve higher a dpi (e.g. 110), so it is worth checking a supplier’s options.

Print size and design complexity also have an impact. Of the various digital choices, TTO transfers the most data, making it ideal for printing dates, product information, logos, nutritional information, ingredient lists and barcodes etc.

For glossy films and foils requiring text with exceptionally high resolution, TIJ may be best but care must be taken to ensure the print does not smudge since the ink does not dry instantly when printing on film.

Laser offers the best permanence. Users needing high durability could also consider CIJ, with specific inks for high adhesion. Another option is a high resin TTO ribbon; this may require lower speed but durability will be better than CIJ.

Generally, where consumables are required, it is important to pick an appropriate one for the application; otherwise, codes may fade prematurely, smear, be susceptible to tampering etc. A knowledgeable supplier is vital to ensuring the necessary quality.

In terms of cost, it depends whether the priority is to minimize capital versus operating expenses.

A good laser, set up properly, can run for years with no downtime impact and no intervention apart from occasional fume extractor filter replacement and lens cleaning. Its OPEX is negligible.

By contrast, TTO, CIJ and TIJ have lower CAPEX but require ongoing maintenance and consumable purchases.

In TTO the consumable is ribbons. Different types exist for various films, temperatures, chemical and rub resistance requirements and line speeds. Replacement, taking around 30 seconds, is typically needed every few days but, beyond this, very little maintenance is required.

TIJ has all its consumables within the “cartridge” printhead, making for easy maintenance. However, this can result in high costs if the printhead needs changing frequently (e.g., regular high-speed operation).

CIJ requires inks and additives. It is advisable to use modern consumable management systems. These ensure mistakes are impossible and the sealed units eliminate fluid contact. They can be replaced with lines running. With older systems messy spillages are possible and downtime is greater.

Checking accuracy

Manufacturers should confirm they have printed their intended message. Digital technologies enable this.

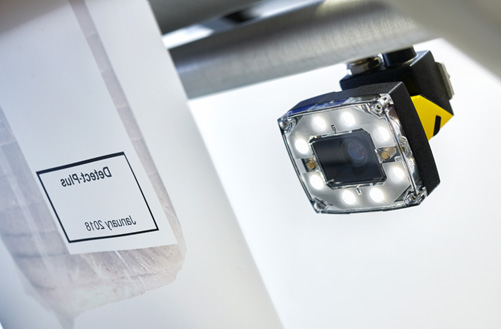

Sophisticated software and camera solutions, often referred to as “Mark and Read”, can be applied with any of the digital options above. Optical character recognition confirms that every print is present, readable and correct. Some solutions even have on-line barcode quality scoring in real time, rather than waiting for periodic lab grading assessments. Problems can be corrected in real-time before too much improperly coded stock is produced, minimizing waste. Given such installations can be complicated, manufacturers should scrutinize a supplier’s track record in providing seamless integration. Alternatively, a coder with this facility ‘built in’ could be chosen.

Some TTO coders offer simpler solutions. One approach checks code presence on flexible film by looking at the ribbon and inferring the information. However, this only identifies that the code has been printed, but not its angle or if it missed the pack entirely. A more accurate method checks the presence, position and quality of printed codes directly on the film packaging itself.

About the Author

Andy Gray BSc(Eng) MIEE CEng

Andy Gray is the marketing manager for thermal transfer overprinting solutions at Markem-Imaje and has been with the company since 1993. Andy is also one of the authors of Markem-Imaje’s white paper on flexible film coding.