The Key Metric of Battery Production — Overall Equipment Efficiency

- Published: February 06, 2025

By Prof. Dr.-Ing. Daniel Eggerath, Technical Director, Jagenberg Converting Solutions

Chris Clark, VP - Sales and Technology, Faustel

Thomas Lebbing, Managing Director, Jagenberg Converting Solutions

The battery, as an energy storage device, has been an integral part of private and industrial applications for many decades. The areas of electromobility and the stationary storage of electricity have triggered a veritable boom in recent years. Battery production facilities have been, and are being built all over the world.

Global storage requirements are currently estimated at 3000 GWh. The U.S. accounts for an estimated 810 GWh, with around 200 GWh of production capacity installed to date. In practice, this often does not correspond to the total quantity of material produced, as the amount of waste during battery production is often not insignificant due to the high complexity of the manufacturing process.

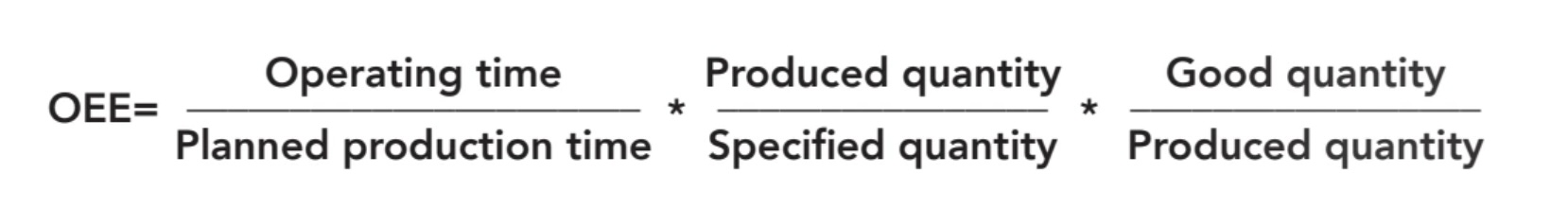

A characteristic metric for assessing production quality is the so-called OEE value (Overall Equipment Efficiency), expressed using the following formula:

Ideally, 100 percent is achieved here. However, in the battery production environment, systems that achieve 87 percent are currently described as world class.

The situation is even more critical during the ramp-up of the systems. Here, values of 40 percent or less are not uncommon. Thus, large sums of money are swallowed up during this time, as the costs for the active materials in the cathode in particular are very high. The aim is therefore to make the ramp-up phase as effective as possible in order to quickly reach an OEE>80 percent.

How can this time be shortened? There is great potential in commissioning the systems in a close partnership between the end customer and the system supplier. A key factor here is the necessary process knowledge that the machine supplier brings to the table to ensure an efficient and effective start-up of the plant in addition to supplying the equipment. Here, for example, a giga-factory electrode coating system can be considered (Figure 1).

Copper and aluminum foil are coated and dried with corresponding electrode materials in the GEMO highest grades on such machines. Typical web speeds are 70 m/min and coating widths of ~1.2 m. The machine lengths are approximately 100 m due to the required dryer length of approximately 50 m. The coating lines are usually installed under clean room conditions, i.e. ambient temperatures of 22°C and room humidity of ~1 percent. An important parameter that significantly influences the OEE is the uniform distribution accuracy of the coated electrode material on the substrate. Both the front and back of the substrate are coated. The basis weights to be applied can vary, although values of 100 g/ m' per side are not uncommon.

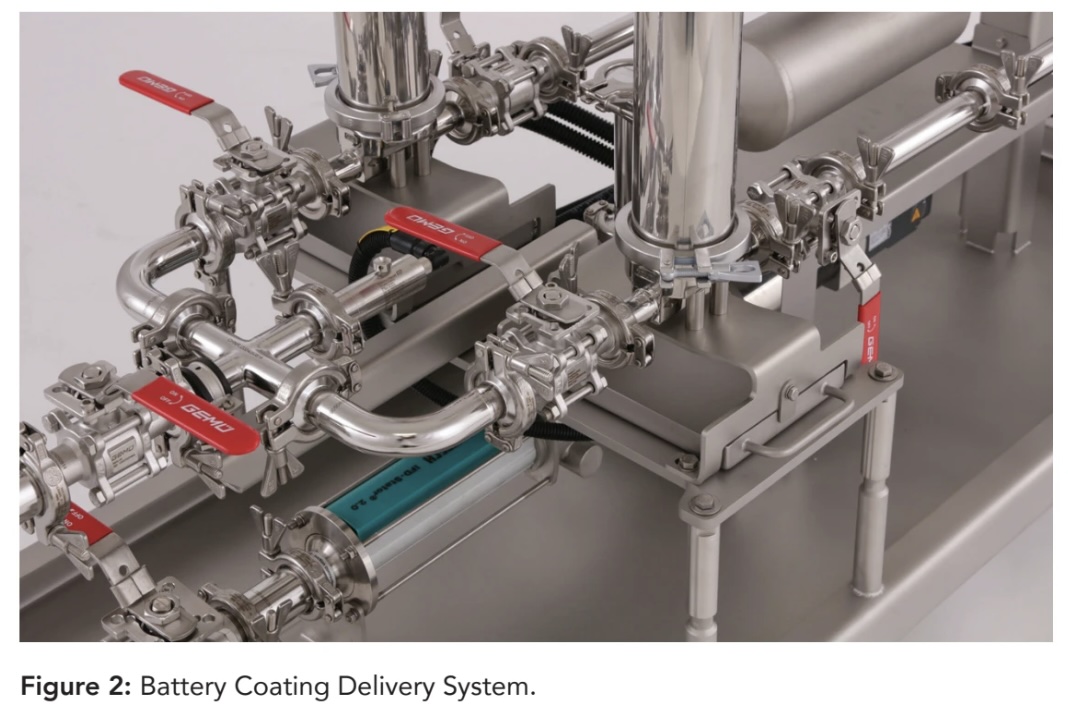

The coating process, which is usually carried out using a slot die, is therefore crucial. On the one hand, precise application is guaranteed by a perfectly manufactured slot die (Figure 3), which means that the outlet gap must be manufactured to an accuracy of less than 1 um. On the other hand, the coating delivery system (Figure 2) must be designed in such a way that there is no accumulation of particles within the slot die and no pulsation of the mass flow, which would lead to linear thickness fluctuations in the direction of web travel.

Another important aspect is the accurate positioning of the slot die, in the micrometer range. Once the distance has been set, it must not change during operation, and it must be consistently reproducible after movement (throw-off). Figure 3 shows an example of such a coating process. In this case, five strips were produced in parallel in the direction of web travel.

The uniform distribution is usually measured using so-called basis weight measuring systems, i.e. the thickness distribution of the coating is measured indirectly via the surface density (g/m?). Various measuring principles are used, such as ultrasound, X-ray, or beta gauge. Which measuring principle is most suitable must be decided on a case-by-case basis according to coating formulation and other factors.

Together, the applied coating precision and the accuracy of the measuring system plays an extremely important role in quality control. If one considers that in some cases uniform distributions of less than +1 percent must be achieved in production, the requirements for the measuring system must be multiplied by a factor of 10, i.e. measuring accuracies of 0.1 percent must be achieved.

The basis weight measuring systems are usually located at different positions within a system, e.g. in wet and dry areas, as well as directly in the area of the base foil or film. Almost all systems face corresponding challenges at the edges, as the measuring spot is in the millimeter range. Confocal laser sensors can help to resolve the edge elevations. The edge elevation is caused by boundary layer processes in the area of the die outlet, as well as capillary and wetting phenomena.

These so-called profilometers are usually placed directly in the wet area of the coating.

Another important aspect is the geometry of the coating. It is not uncommon for several strips to be produced simultaneously, as shown in Figure 3, and on both sides.

For the subsequent processing of the electrode material, it is crucial that the coating preparations do not exceed or fall below certain tolerances, typically in the tenth of a millimeter range. Optical systems are therefore used to maintain the tolerances. In addition to detecting defects, e.g. contamination, they also measure the geometries of the electrodes. In addition to the measuring methods already mentioned, there are many other measuring techniques within such systems to ensure flawlessly produced electrodes.

After understanding the aspects that influence the OEE of electrode production, we can now summarize five key solutions that ensure that the OEE quickly exceeds 87 percent during the commissioning phase:

- Pre-order process trials at a Technology Center to demonstrate the supplier's mission critical technologies, such as slot die coating accuracy and coating delivery system performance.

- Closely coordinated project planning between the machine supplier and the customer throughout the design and production of the machine.

- Continuing process engineering support from the system supplier to solve any process equipment problems during the commissioning phase.

- Flexible and fast-acting system supplier in the event of problems.

- Integrated central data management system for the analysis and optimization of the electrode being produced.

In conclusion, it can be said that the production of a battery electrode poses many challenges. However, these can be mastered effectively by considering all relevant process parameters in partnership between the customer and an experienced equipment supplier, followed with a structured and systematic commissioning phase.

About the Author

Jagenberg Converting Solutions and Faustel are two leading companies in the web converting industry, partnering to provide equipment from R&D scale through complete giga-factory solutions. Faustel's Process Technology Center facilitates collaborative customer product development trials prior to equipment manufacturing. For more information, email This email address is being protected from spambots. You need JavaScript enabled to view it. or This email address is being protected from spambots. You need JavaScript enabled to view it..