Nordson to Bring a Level of Control Never Before Seen in Flexible Packaging Manufacturing

- Published: January 16, 2025

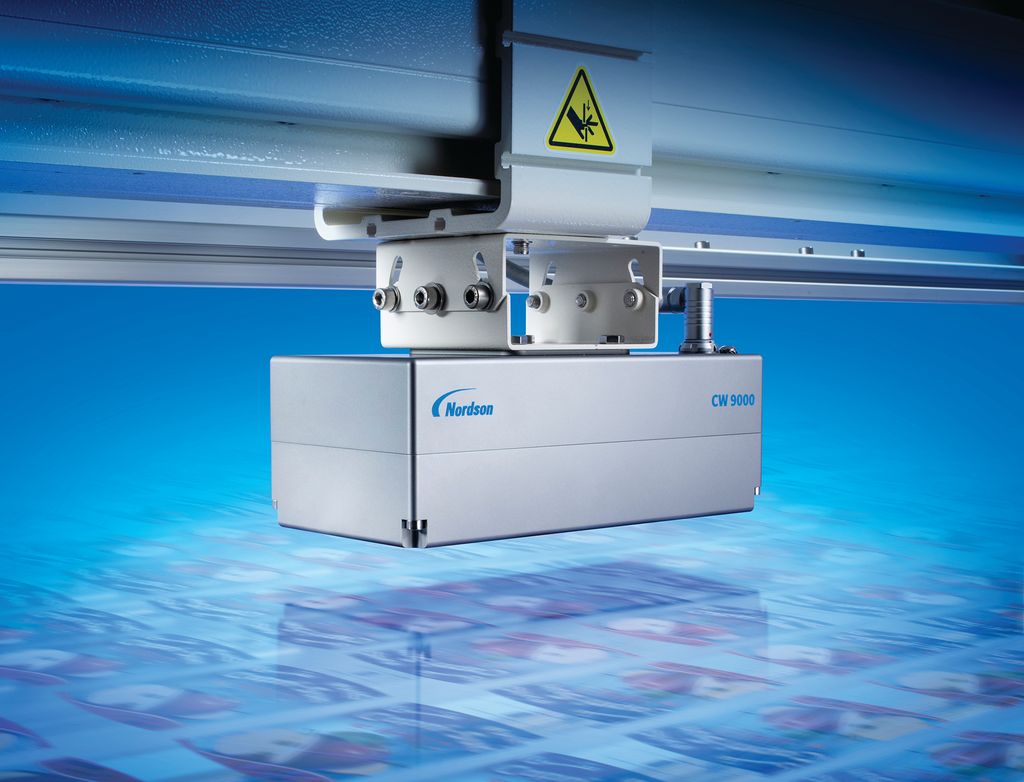

Nordson has recently launched a new compact coat weight system for adhesive measurement of flexible packaging manufactured on coating and laminating lines -- the CW 9000. “The new CW 9000 makes possible what flexible packaging manufacturers have been asking for – accurate and fast adhesive coat weight and mix ratio measurements,” said Chris Vierra, Product Manager for Nordson’s film extrusion and converting businesses. “Nordson worked with several OEM line manufacturers and flexible packaging customers to make sure that this system would be a game changer. At a glance – operators and other personnel can immediately see key quality indicators. Coat weight and mix ratio profiles are available after a single scan - providing the operator with immediate information needed to confirm quality and make any necessary process adjustments. A trend display shows if the coating goes outside of tolerance to enable corrective actions before a problem appears. The results are shortened startup time, reduced scrap, and minimized adhesive usage. All while maintaining product quality!”

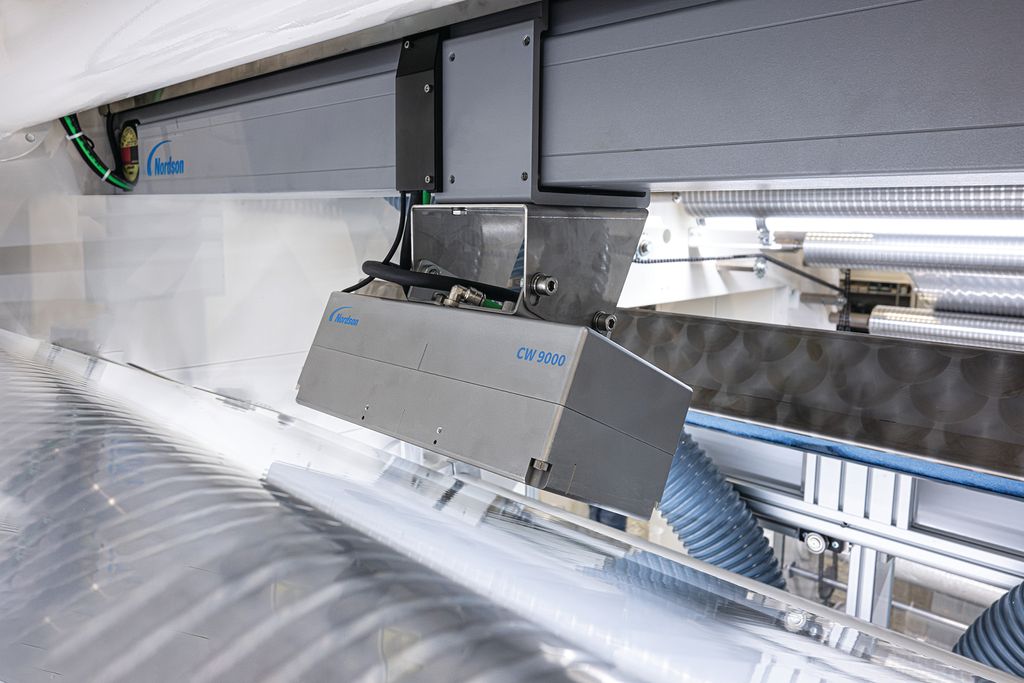

The system is built to work with Nordson’s proven Pro.Net Total Distributed Intelligence system. It includes the new compact CW 9000 sensor combined with the new LPS 1000 Scanner.

At the heart of the CW 9000 gauge is Nordson’s infrared sensor engine adapted through extensive R&D and proven with online testing. Fast bi-directional scanning updates at the end of each scan with maximum coverage of your production run. Unique infrared optics are coupled with advanced algorithms to achieve measurement resolution and performance meeting the quality demands of the flexible packaging industry. Applications include clear films, printed films, aluminum foils, and metalized film or paper. The sensor is highly flexible and capable of measuring other coatings besides polyurethane. Nordson’s applications team will be happy to evaluate your specific needs.

The LPS 1000 is a self-contained Low-Profile Scanner that fits inside the frame of compact coating machines. It can perform fast scans and operate in a single point to analyze machine direction variations. The enclosed scanning frame prevents dirt from the scanner from falling onto the coating; it is easy to maintain and easy to remove from the coating frame. The precise motor/drive system delivers optimal positioning.

The Pro.Net user interface provides real-time process quality, automatic coat weight control (if properly interfaced with the machine), and alarms. The display is user-configurable supporting multiple informative display boxes all on a single high-resolution screen. Some of the selectable display boxes are trends, profiles, zone data, zone statistics, roll statistics, and historical coat weight via colored profile/3D map. The Pro.Net system supports multiple recipes and selectable reporting tools. Last but not least, it features an embedded OPC-UA communication package to export/import valuable data and information.

For those interested in close loop control, Nordson has developed a special version of the system, called NM 9000, in cooperation with one of the industry’s largest OEMs, Nordmeccanica. The NM 9000 system can be fully integrated into all new Nordmeccanica machines providing an unprecedented level of control. It is also possible to retrofit old models to include the system.

For more information and contacts, visit www.ndc.com.