Maplesoft – Flexible Simulation Solutions to Address Your R2R Issues

- Published: January 16, 2025

Why use Simulation?

Web handling equipment suppliers and manufacturers of paper, film, plastics, and EV batteries are turning to modeling and simulation to improve handling and tension management, and in turn make product quality more consistent.

Simulation is a cost-effective way to fill the gaps in your knowledge about your web system, and tackle your web line pain-points, such as optimizing throughput, preventing quality issues, or reducing wastage. Digital models can be used to narrow down setpoints and web line designs, before you commit to expensive hardware changes or an overload of sensors. It also offers a virtual testing platform to troubleshoot or verify tension control strategies before applying them on the production machine.

What does Maplesoft offer?

Maplesoft is a leading provider of advanced modeling and calculation solutions for engineering, science and mathematics, used by 8000+ organizations in over 90 countries.

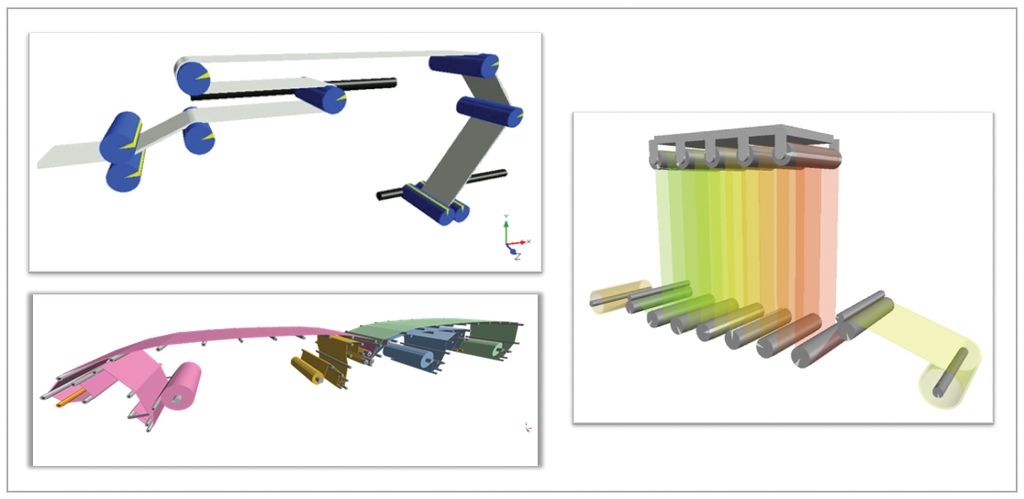

- The MapleSim advanced modeling software supports R2R engineers to maintain product quality by exploring the web material response to roller layouts, and determining tension setpoints.

- MapleSim has a specialty Web Handling Library of pre-built components to make it simple to model dancers, nips, idlers, and driven rollers, and is far quicker than creating 3-D CAE mesh models.

- Maplesoft also offers consulting support and modeling experience to help get more value from developing a virtual model of your roll-to-roll system.

Which industries use simulation?

Our customers include manufacturers of high volume lines for paper, flexible packaging, plastics, and films, and we are seeing growth in emerging verticals where the thin products are particularly sensitive to breakage and tension quality issues, such as battery and electronics industries.

How is MapleSim simulation used?

MapleSim is a valuable modeling tool for engineers working on:

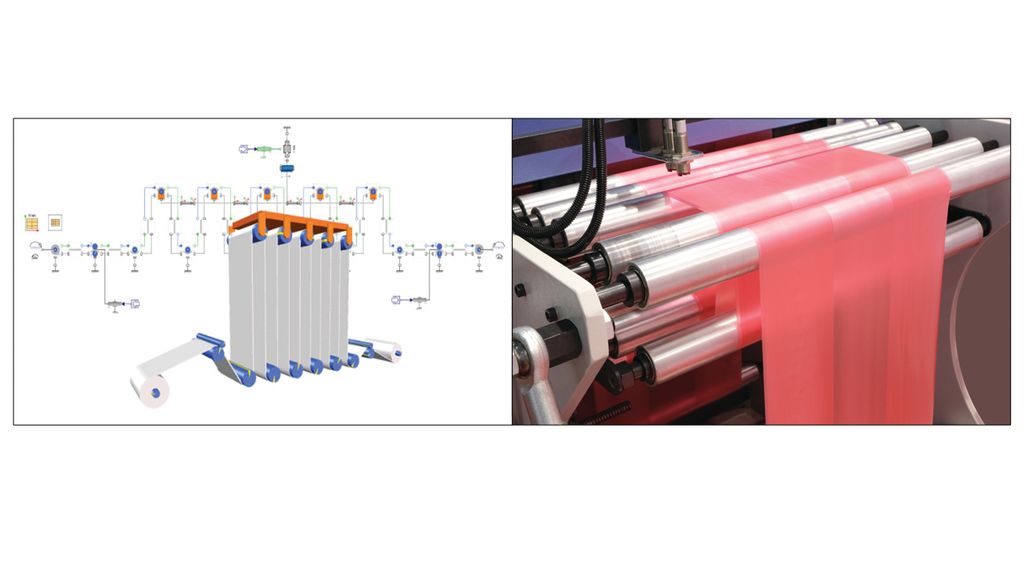

TENSION CONTROL: You can determine the tension setpoints and web speed that avoid stretching or damaging the product, by modeling the roller layout in MapleSim. 3-D visualizations show how web span tension varies over time, giving you confidence before applying the settings to a physical machine.

TESTING SOLUTIONS TO PRODUCT QUALITY ISSUES: Product quality issues on a high-volume web line can be time consuming to track down. Whilst “set and test” has its place in initial triage, MapleSim acts as a virtual testing platform to try out combinations of parameter changes and see the effects of changing drive or brake settings. You can also simulate how materials with different properties will run through the web line.

VALIDATING CONTROL STRATEGIES: For precise control during converting and laminating processes, a MapleSim digital model can reveal insights about your machine operations. With flexible connectivity options to common automation tools (including Rockwell Automation, B&R, CodeSYS, Siemens, and more), you can validate your controller code or dancer motion profile against the MapleSim virtual roller elements to confirm downstream web responses.

Getting started with simulation

Our experienced simulation specialists would be happy to discuss your converting or web handling project, and suggest ways simulation may be useful to your R2R system.

For more information visit www.maplesoft.com/rolltoroll or contact Eric Drouillard at This email address is being protected from spambots. You need JavaScript enabled to view it. (direct 1-226-752-5864).