Battery Show 2023: Meech Demonstrates Importance of Static Control, Surface Cleaning in Battery Manufacturing

- Published: May 23, 2023

Meech International will present its range of static control and web cleaning solutions at The Battery Show 2023 (Booth 10-H100), May 23-25, 2023.

Meech International will present its range of static control and web cleaning solutions at The Battery Show 2023 (Booth 10-H100), May 23-25, 2023.

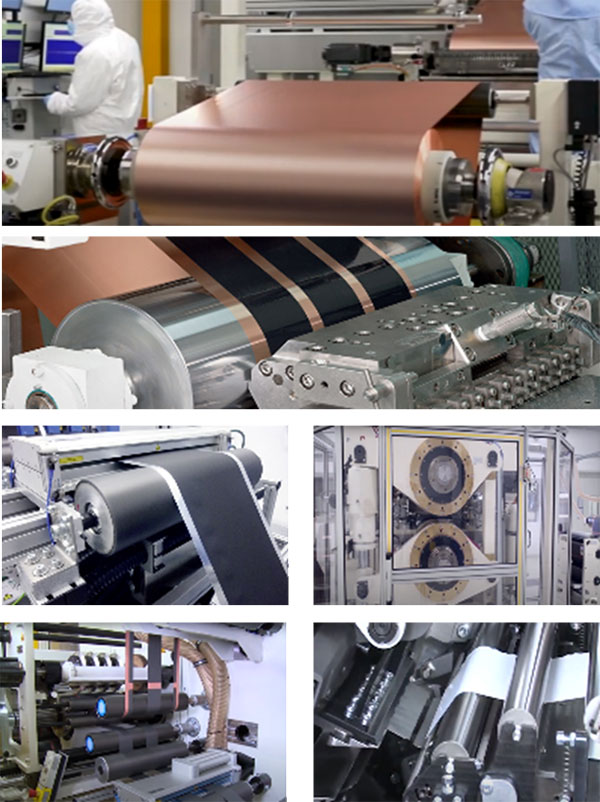

Static control and surface cleaning are critical in the battery manufacturing process for the removal of contamination and to ensure optimum, high-quality output. Meech offers a dedicated approach to surface contamination and static charge removal with a range of solutions, tailored to the battery manufacturing industry, which can be matched to the material, process and contamination type.

In March 2023, Meech underlined its expertise in the sector by hosting the webinar: “Avoiding thermal runaway in EV batteries.” Held in partnership with subject expert Dr. Paul Christensen, this successful webinar examined multiple causes of thermal runaway, including dangerous contamination within the manufacturing process, and how specialised static control and web cleaning solutions can help to reduce this risk. Professor Christensen offered a compelling perspective by stating, "There is strong evidence to suggest that spontaneous fires are often attributable to contamination or manufacturing defects." This statement effectively highlights the critical significance of contamination removal and manufacturing quality within the battery industry. The Battery Show 2023 comes at the perfect time for Meech to develop and build on this message.

Products on display at The Battery Show include:

RoClean C

Unlike other brush cleaning web cleaners on market, RoClean-C combines dynamic air flow and rotating brush technology. The battery web passes through an ionisation cloud on entrance and exit, while the brushes rotates in the opposite direction to the web for thorough disruption of any challenging contamination particles. Contaminants are drawn into the vacuum chamber. The positive air flow not only disrupts contamination on the web, but it also ensures that any contamination left on the brush is also moved to vacuum chamber.

Cyclean R

CyClean-R incorporates advanced computational fluid dynamics that allow converters to thoroughly clean low-tension webs.

Ideal for use in a wide variety of applications, including narrow, mid and wide web, CyClean-R is available as a single-sided and double-sided web cleaner. From its position on the web roller, it delivers optimal, consistent removal of dry, unbonded contamination from any web material (particle removal to 0.5 micron is achievable).

Compact AHU

The Meech AHUv3 range is integral to the Cyclean-R™ and RoClean™ specialised surface cleaners. The AHUv3 provides positive and vacuum pressure airflows and houses the system filters. It is of robust design and requires minimal maintenance.

Smart Control Touch

SmartControl Touch harnesses the power of Industry 4.0 within scaled up battery manufacturing applications by connecting multiple ionisation bars and sensors for advanced monitoring and control. This system offers improved productivity, quality and safety assurance. The unit allows users to monitor, control and adjust the performance of multiple connected Hyperion ionising bars and distance sensors via an integrated touchscreen, or remotely via a mobile phone, tablet, or desktop.

Hyperion bars

Meech’s Hyperion pulsed DC ionising bars – the 971IPS, 960IPS, 924IPS, and 314IPS provide short, medium and long-distance static elimination respectively, and can be installed quickly and easily onto converter’s lines.

For further information, visit www.meech.com.