A Deeper Look at UV Inks in Label Production

- Published: August 17, 2024

By Mike Pruitt, senior product manager, Epson America, Inc.

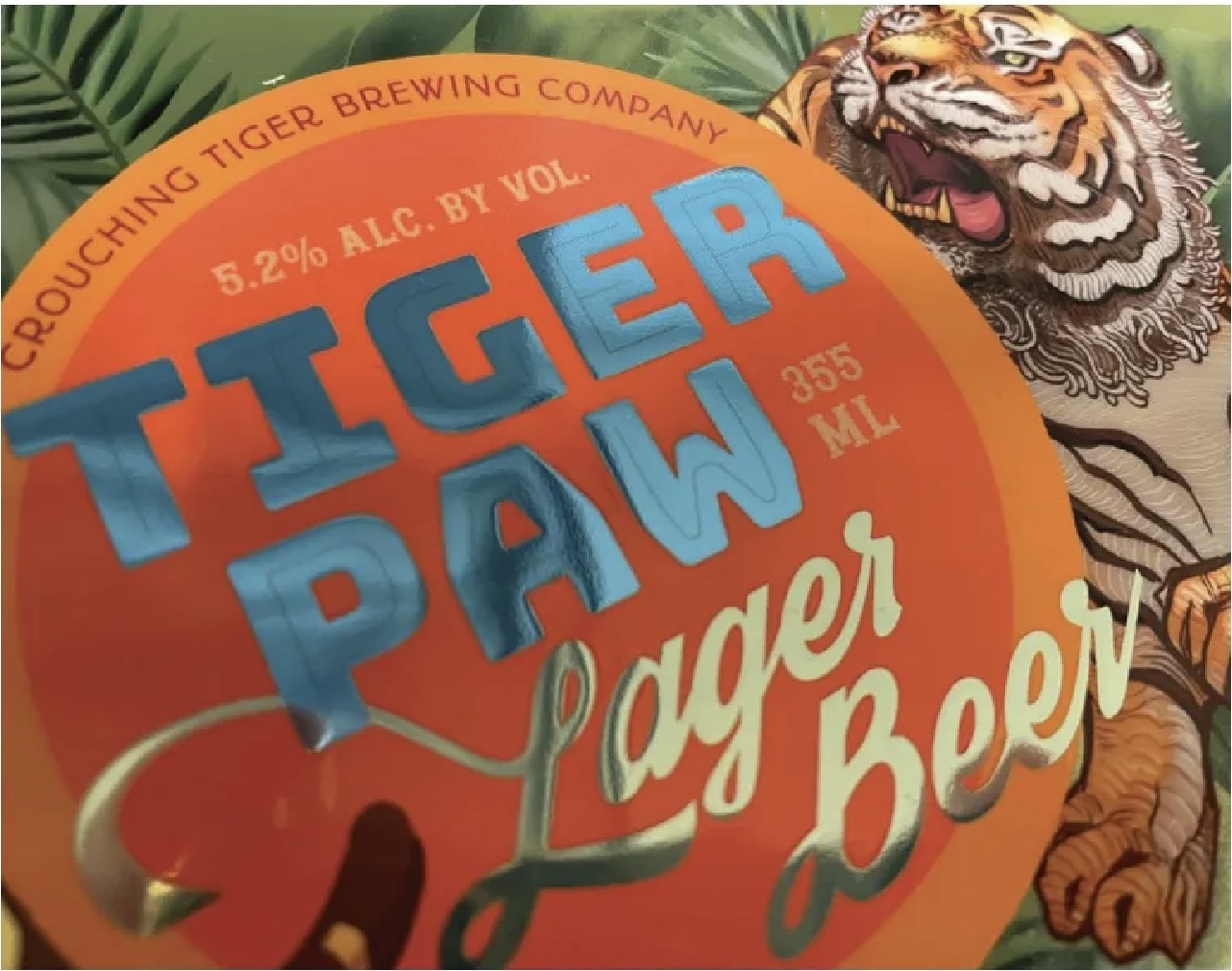

The use of UV inks in flexo and digital production has continued to grow in 2024 for a variety of reasons. Low VOC content, high print speeds enabled by fast curing, UV compatible substrates readily available, low power consumption, high print quality and embellishment capabilities have all impacted the ongoing growth of UV label printing.

From the manufacturing front, UV inks are being updated regularly to comply with ever tighter European Printing Ink Association (EUPIA) safety standards. Coupled with digital advancements, inkjet technology has made significant strides, boasting features such as thin, precise flat ink laydown, sharper text, sophisticated dot placement, and registration capabilities that can produce G7 print quality and wide color gamut, reliably fast printing speeds, color repeatability and the jetting of clear inks for embellishment. Given all this, what's NOT to like about UV inks?

It is important to note that UV inks require careful consideration of the substrate material. Many substrate suppliers have adjusted their standard offerings with a universal topcoat that is UV compatible. This has greatly helped from an inventory and cost standpoint; now a converter is able to use the same material for both flexo and digital jobs. Although convenient, the substrate plays a critical role in ink adhesion, and it's up to the converter to assess ink and substrate compatibility to ensure proper ink adhesive and avoid chipping of the ink in the finishing process during die cutting and wear in normal transportation and use.

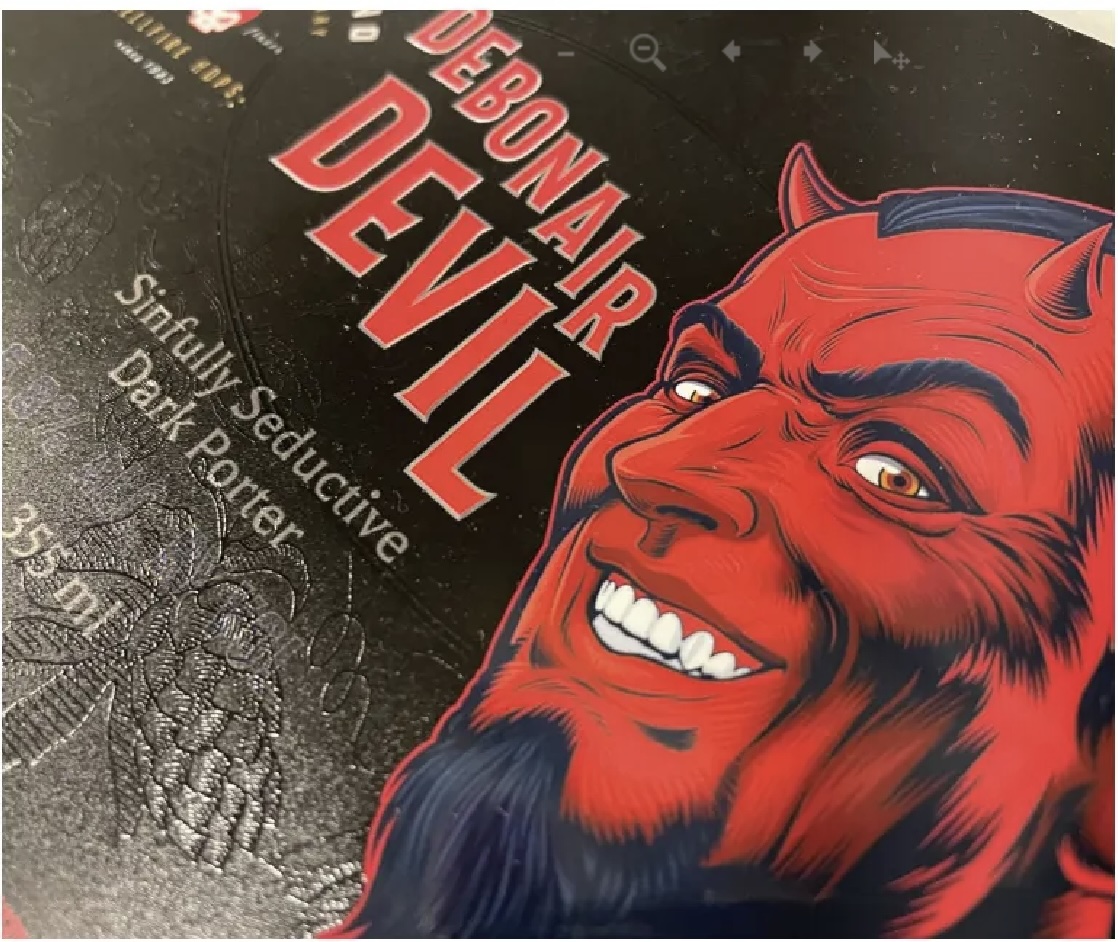

It is industry standard to laminate or varnish the label after printing to protect the surface print during the labeling, shipping, display and use of the product. However, in processes like UV clear ink embellishment, it's recommended to never apply the lamination or liquid vanish post-print as it can damage the embellishment effect.

In these cases, ink adhesion is critical due to lack of surface protection which the lamination or varnish would provide.

Typically, printer manufacturers conduct tests to categorize adhesion into tiers. Tier 1 will pass a tape lift-off test with a small cut in the material, while tier 2 will pass without any cuts in the material. There are more advanced tests for critical applications that a converter can research. However, it's recommended a print provider should always strive to use a Tier 1 ink and substrate combination when available and is cost effective.

For those converters looking to utilize materials that pose challenges with adhesion, methods like corona treating and priming can be used to enhance adhesion. For materials without a topcoat, corona treatment can be used to improve adhesion. Corona treatment is a process that increases the surface energy of the material, it improves wettability affecting print quality and surface adhesion.

Corona treatment is typically done at the time of substrate production and supplemented inline on the press proceeding printing. Despite the automation of printing processes, setting the corona level is still an art and can be time consuming. An alternative is to coat the substrate with a water-based, or more typically, UV primer. Regardless of the preferred method, this adds a step to the printing process, necessitating priming either offline or inline with a flexo station.

UV ink typically performs best on filmic materials. Even a semi-gloss has some filmic properties. Uncoated substrates, such as Estate 8 used in the wine industry, lack these filmic properties. This can cause the UV ink spread to be uneven, and therefore won't match the classic look of a water-based ink. Thus, while UV printing on un-coated materials is feasible, it's best approached on a case-by-case basis.

Another area of development with UV inks lies in shrink film applications. Whereas UV inks demonstrate efficacy at a 30 percent shrink rate, reliably getting digitally printed UV to resist cracking at 70 percent shrink can be a challenge. Ink manufacturers are actively working to develop thinner and more flexible ink formulations tailored for high-shrink and squeeze tube applications.

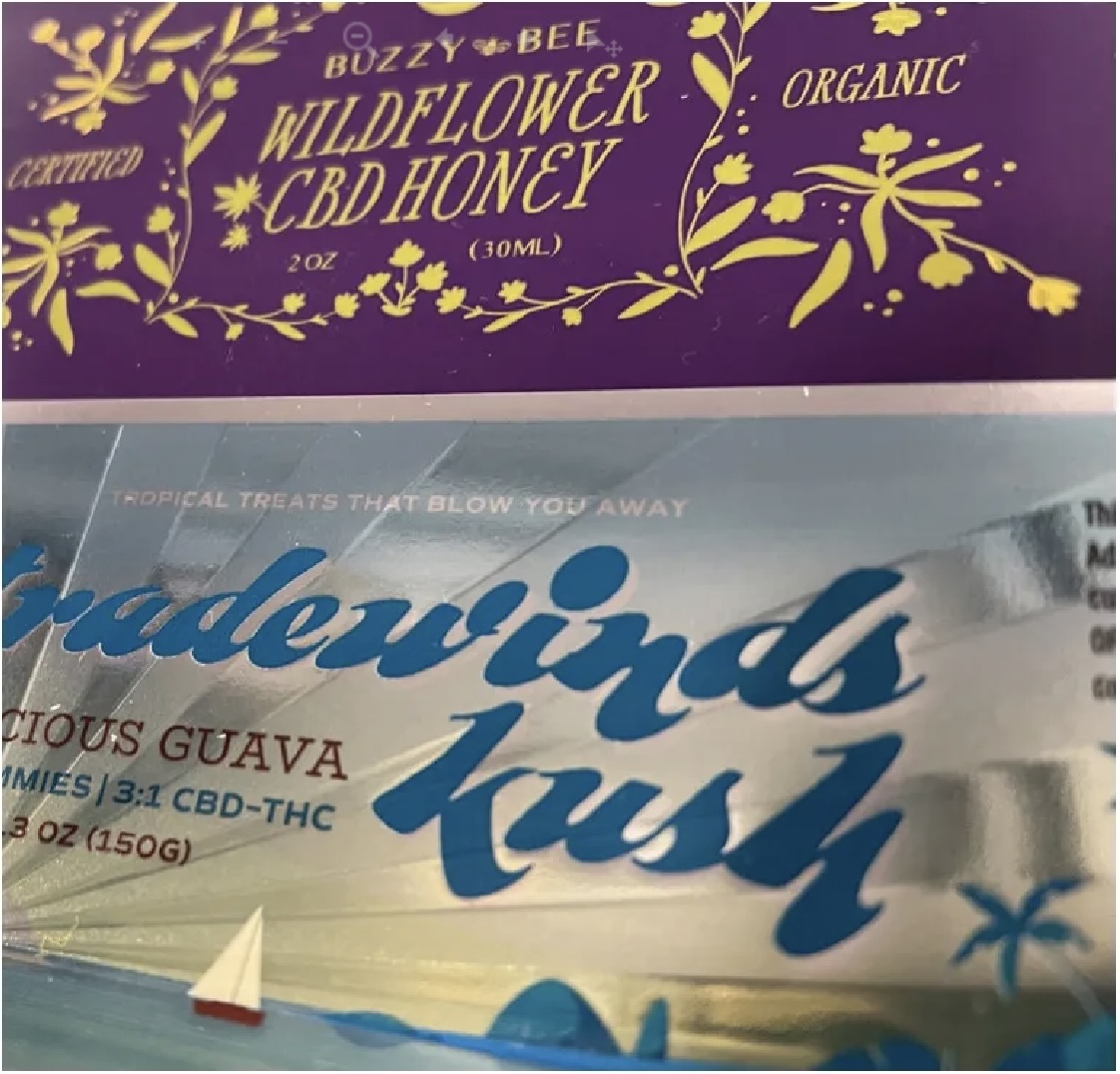

Ink manufacturers have already made significant strides in ink development, creating formulations that excel in low migration, low odor, ever thinner laydown and continued compliance with regulations such as EUPIA. Some manufacturers have gone as far as building their ink manufacturing plants to Good Manufacturing Practices (GMP), which not only ensures product quality but also aids converter customers in meeting stringent food safety regulations.

So, what about water-based inks? Water-based inks, particularly those used in digital printing, historically need a special coating for substrate adhesion. In the past decade, resin and latex encapsulated inks have been developed, and when heated after printing, fuse to even non-top coated films.

As remarkable as this 1s, the drying process for these inks consumes considerable time and energy, which influences print speeds, making it significantly slower than UV ink prints. Because water-based inks are favored by the food industry and perform remarkably well on most substrates, including the uncoated substrates where UV inks have issues, continued research efforts persist to develop more sophisticated drying methods and faster print speeds.

So, what is in the future? Automation is key, driven by factors like the shortage of skilled machine operators and cost considerations. Sophisticated printing and ink systems, whether digitally controlled on a flexo or inkjet digital press, will contribute to the stability needed to fully automate systems.

These systems meticulously manage inks for temperature, solid control, dot placement, spread and conversion to a final cured print. Such control is achieved consistently and without operator input, paving the way for systems capable of handling daily maintenance autonomously.

About the Author

Mike Pruitt is senior product manager for the SurePress digital label press at Epson America, Inc. In his role, Mike is responsible for driving prime label printer activities within industries such as wine, nutrition and specialty food products.