Gravure Print and Coating Quality Contenders

- Published: November 09, 2023

By Tom Kerchiss, chairman, RK Print Coat Instruments Ltd.

Print buyers, packaging technologists and others with an interest in printing and converting processes such as coating and laminating will be aware that the market for gravure has changed and that in many respects gravure has shifted direction.

Print buyers, packaging technologists and others with an interest in printing and converting processes such as coating and laminating will be aware that the market for gravure has changed and that in many respects gravure has shifted direction.

Gravure once tended to be associated with the printing of glossy publications, fashion,

TV Guides, mail order catalogs and quality newspapers. It was the process most closely able to accurately replicate and reproduce a photographic image on the page. It came into its own with the printing of weekend color supplements and pull out comic/fashion and lifestyle sections of national newspapers; those with big circulations that relied on photo-quality print to attract and keep readers and advertisers happy.

But as we all know from experience, times change and so, too, do the markets. Printers and converters and the processes they use have to adapt. Gravure as a process is resilient and adaptable.

Publication and catalogue printing declined over time, for the most part brought about by declining circulations, falling advertising revenues and the introduction of digitized editions of magazines and other publications.

Fortunately, gravure was never just about publication printing. Consider for example, decorative laminates. Decorative laminates are one of a number of design options to enhance the appearance of homes, conference centers, hotels and entertainment venues. Decorative laminates are widely used for automotive, marine and aeronautic applications, indeed any area where attention is given to presentation, comfort and luxury.

Decorative laminates are structures made of multiple layers of film and other materials combined together which are printed and converted using printing processes such as gravure print and coating. On completion the finished product simulates very expensive and often scarce, difficult to extract or manipulate, heavy metals, hard woods and ores.

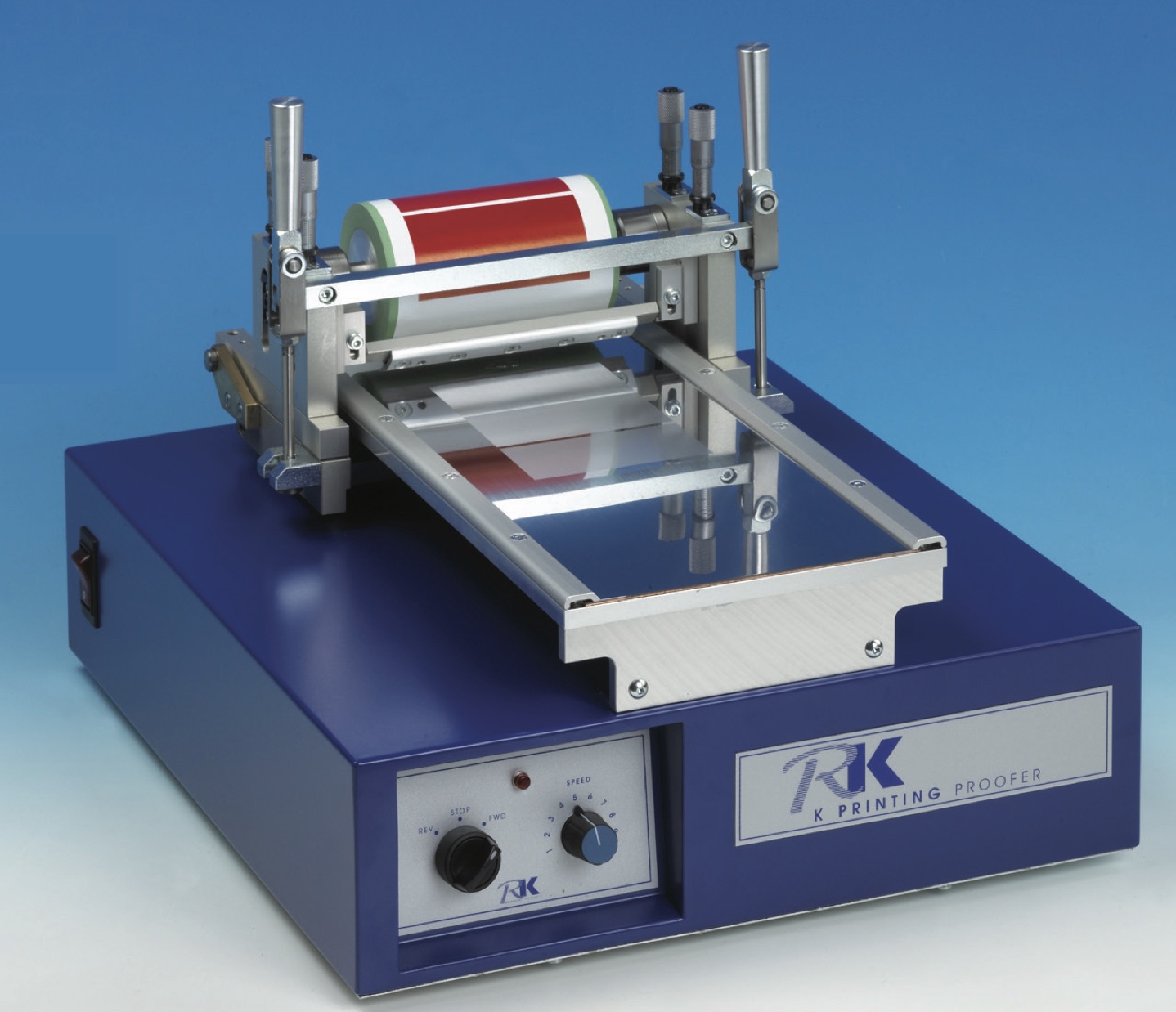

Materials that can be realistically rendered include mahogany, teak and ebony, chrome, brick, granite, marble and much more besides. Sometimes they can be K Printing Proofer with Gravure Head manufactured in the form of foils. Regardless of the appearance of the end product, the majority of printed/coated layers consist of clear layers, decorative layers and a core base or foundation layer. Most items begin with a clear coat that is either produced via extrusion or manufactured using a cast film technique so as to create a lower stress product. The resultant clear-coated layer is often of a high gloss but it can be of a matte finish or manipulated to produce a textured finish.

The next stage in the process is to apply some form of decoration in with the clear coat. The function of the clear coat is to protect the decorative medium from the rigors of the environment. For applications where the main decorative theme is a pattern or patterns, the gravure print process is employed as nearly any pattern can be duplicated or repeated on a continuous basis. Technical finishes, brushed and distressed metals; wood grains; organic patterns or themes can all be rendered looking genuine and natural using gravure print processes.

The decorative printed layer is positioned between the clear layer and the substrate. A primer is applied to the substrate to ensure optimum adhesion. The decorative layer must be protected as many laminates, for example kitchen worktops, are subject over time to the harsh abrasive action of chemical cleaning products. The base layer is much thicker than the other layers and provides the rigidity and strength that the structure needs.

The decorative printed layer is positioned between the clear layer and the substrate. A primer is applied to the substrate to ensure optimum adhesion. The decorative layer must be protected as many laminates, for example kitchen worktops, are subject over time to the harsh abrasive action of chemical cleaning products. The base layer is much thicker than the other layers and provides the rigidity and strength that the structure needs.

Gravure printing and coating of décor offers practical, functional, aesthetic and economic benefits. For a moment consider the gravure printing of a wood grain pattern for laminate flooring. With a natural wood product there are natural geometrical limitations in that the wood grain effect only stretches within defined parameters. Gravure, on the other hand, permits any number of repeats to be made.

Because of gravure’s remarkable density range it is also used for printing fine art prints, greeting cards, gift-wrap and for security items and for other applications where presentation is important. Gravure has and is being used for packaging work, often for quality driven flexible packaging. For added value work, inline operations are well suited to gravure. Cold seal, varnishing, laminating and sheeting are a few of the possibilities.

Higher press speeds and low waste are claimed benefits. The process is also simple to execute and once gravure is set up and running there is theoretically little to go wrong. Gravure can, if need be, work well with cheap or poor quality papers.

Gravure coating differs from gravure printing in that gravure coating provides uniform coverage of the substrate whereas gravure printing prints defined patterns with good edge definition and resolution. Some electronic products however require uniform coverage and good edge definition.

Gravure is available in a number of arrangements. Common variants include direct/indirect, reverse and gravure offset, etc. The gravure direct uses engraved anilox cylinders with various cell shapes, screens and depths to apply for example, lacquers and varnishes. Coat weight is determined by gravure roll volume and by coating solids. Gravure-offset can be used where the design benefits from the softening effect that the rubber-offset roller provides. Areas of applications include the printing of frozen food packaging. Low coat weights are one the most important benefits. But, regardless of the coating method, experimentation to see what works best is recommended in order that commercial and product viability requirements are met.

About the Author

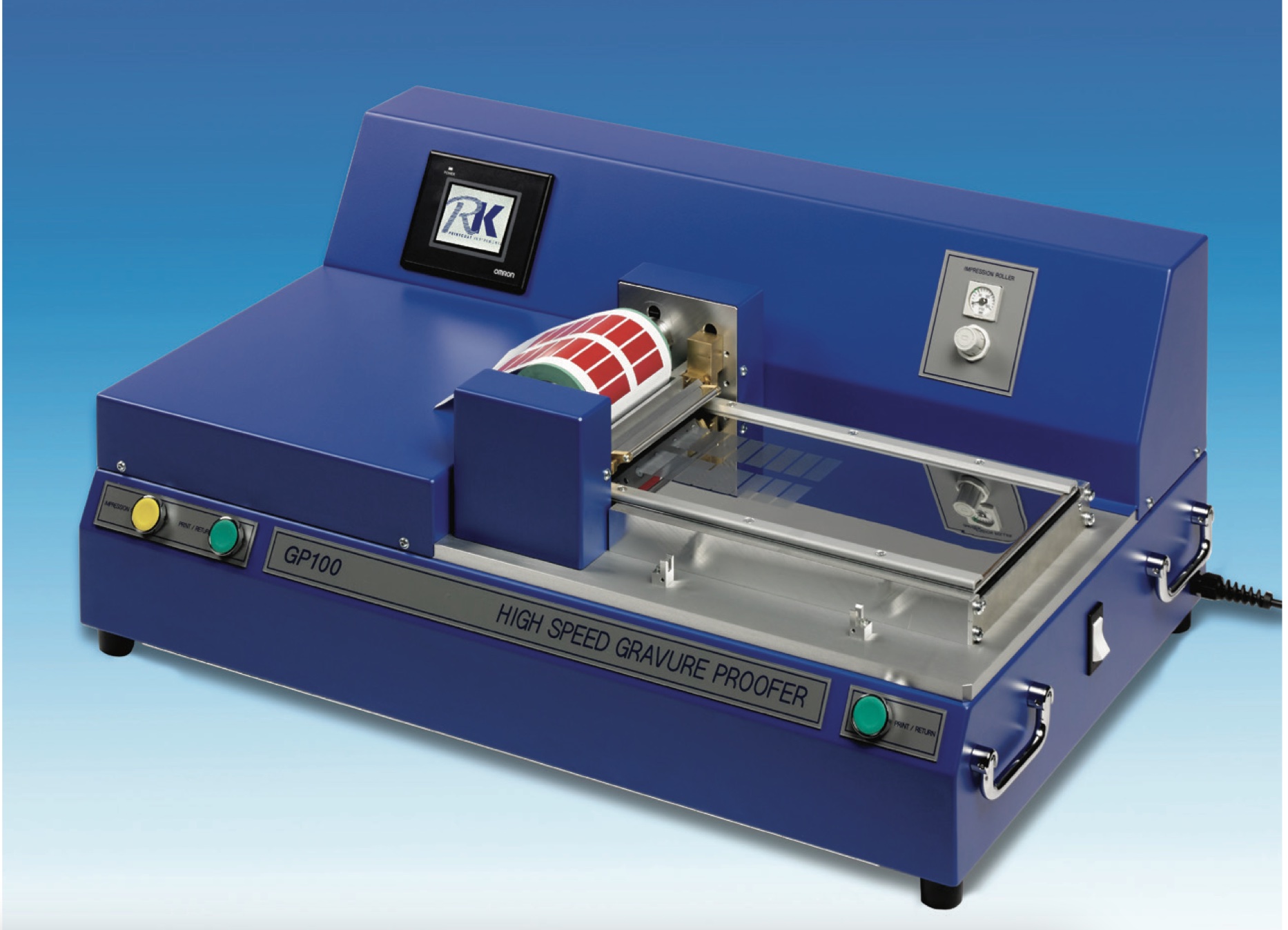

Tom Kerchiss is the chairman of sample preparation system and print/coat/laminating technology specialist RK PrintCoat Instruments Ltd. The company, which won an Innovator in Pre-Press Award for the FlexiProof 100, supplies printing ink manufacturers, both large and small, as well as printers, converters and other businesses with color communication devices for all of the major print disciplines.