Interview with Ryan Schuelke, Enercon President & Chief Sales Officer

- Published: April 24, 2023

What has it been like to take on the role of President of Enercon at a time when the company is experiencing rapid growth?

What has it been like to take on the role of President of Enercon at a time when the company is experiencing rapid growth?

It’s extremely gratifying that our customers have put their trust in us and rewarded our employees’ efforts with record sales and shipments. Enercon is widely recognized as the number one brand in surface treating and our team is steadfastly focused on ensuring our customers’ success. We have an amazing team that knows surface treating applications inside and out, understands the importance of ease of use & reliability, and most importantly has a passion for customer support. I’ve never been more excited about the future of the company.

- How is Enercon keeping pace with the tremendous growth the company is experiencing?

That’s a great question. We are making significant investments in our facilities, people and structure. Our manufacturing operations are being scaled so that we can increase capacity for our customers’ high level of demand. We’ve also added specialized talent in the manufacturing, quality, R&D, sales and customer support areas as we build for the future. This is all driven by our goal to ensure our customers enjoy the highest level of uptime and a remarkable customer experience.

- What separates Enercon from other surface treating suppliers?

Enercon was founded on the premise that you need to understand your customer’s application, commit to building the highest quality products, and invest in supporting customers long after the sale. We know that each customer has unique needs and we’re passionate about providing them with the highest quality products and the best service possible. In solving thousands and thousands of printing, coating, laminating, and blown-film surface treating applications we’ve amassed an unparalleled database of knowledge. With this expertise our application engineers customize equipment for each OEM, converter and extruder to optimize performance for their specific needs. And, our laboratory is the only one that offers corona, plasma & flame making it the ideal place for customers to prove their newest applications and troubleshoot existing issues.

- How is Enercon’s technology different?

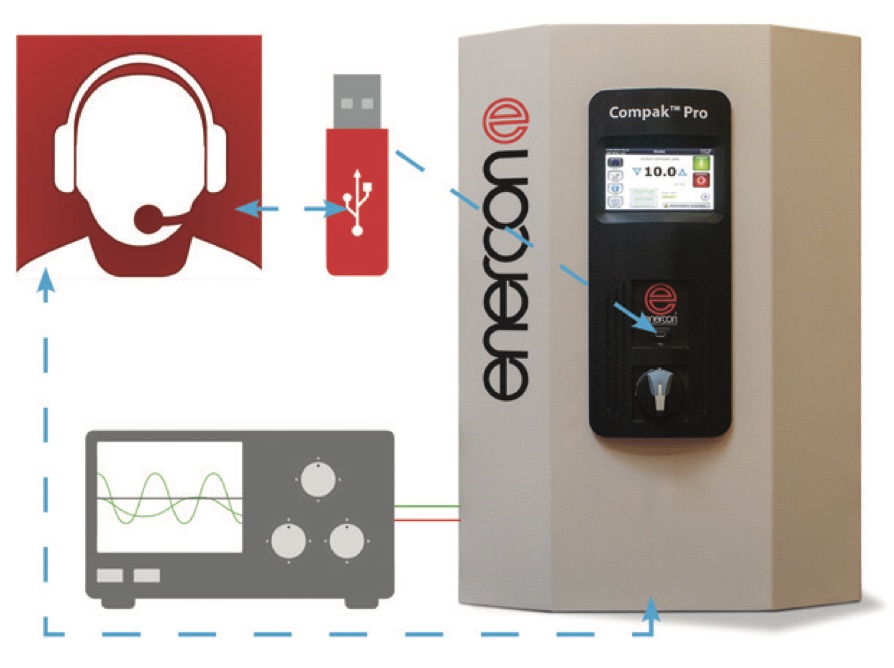

Enercon is recognized both for its reliability and innovation. We pioneered the use of atmospheric plasma technology for film applications. We developed High Definition Corona and our power supply technology has always been legendary for its reliability. In fact, when our customers have a competitive piece of equipment on their line we are often asked to replace the power supply with ours until they can budget for a new treater station. Reliability is important, but we also focus on how our customers use our equipment. That’s why our Compak Pro line of power supplies incorporates artificial intelligence, integrated troubleshooting, maintenance reminders and capabilities for remote diagnostics and support.

- You mentioned Enercon is passionate about support - can you tell us more about that?

I encourage anyone with a question about surface treating and related topics to call Enercon. It’s the best way to discover how our employees are just wired differently. You don’t even need to be a customer, we’re happy to help and share our expertise. Whether it’s about a new application or troubleshooting an issue, our team is here for you. It’s why we staff the industry’s largest support team. It’s who we are and we consider it our responsibility to give back to the industry by sharing our insights and learning from our customers.

For more information visit: www.enerconind.com/treating or call +1.262.255-6070