Understanding Dyne Decay

- Published: March 13, 2023

What is it and Why is it Important to Understand?

By Jan Eisby, CSO at Vetaphone A/S, Denmark

To those involved in extruding, printing, laminating and converting filmic substrates, knowing and understanding the importance of dyne levels is an everyday occurrence — or it should be. But market research indicates that while surface treatment is universally accepted as an essential process, the science behind it is less well understood. In today’s competitive marketplace, where production errors can be costly, knowledge is a powerful commercial tool.

If you want to stay one step ahead, understanding the process and importance of dyne decay can be the difference between profit and loss, as this article explains.

Surface Treatment and Dyne Levels

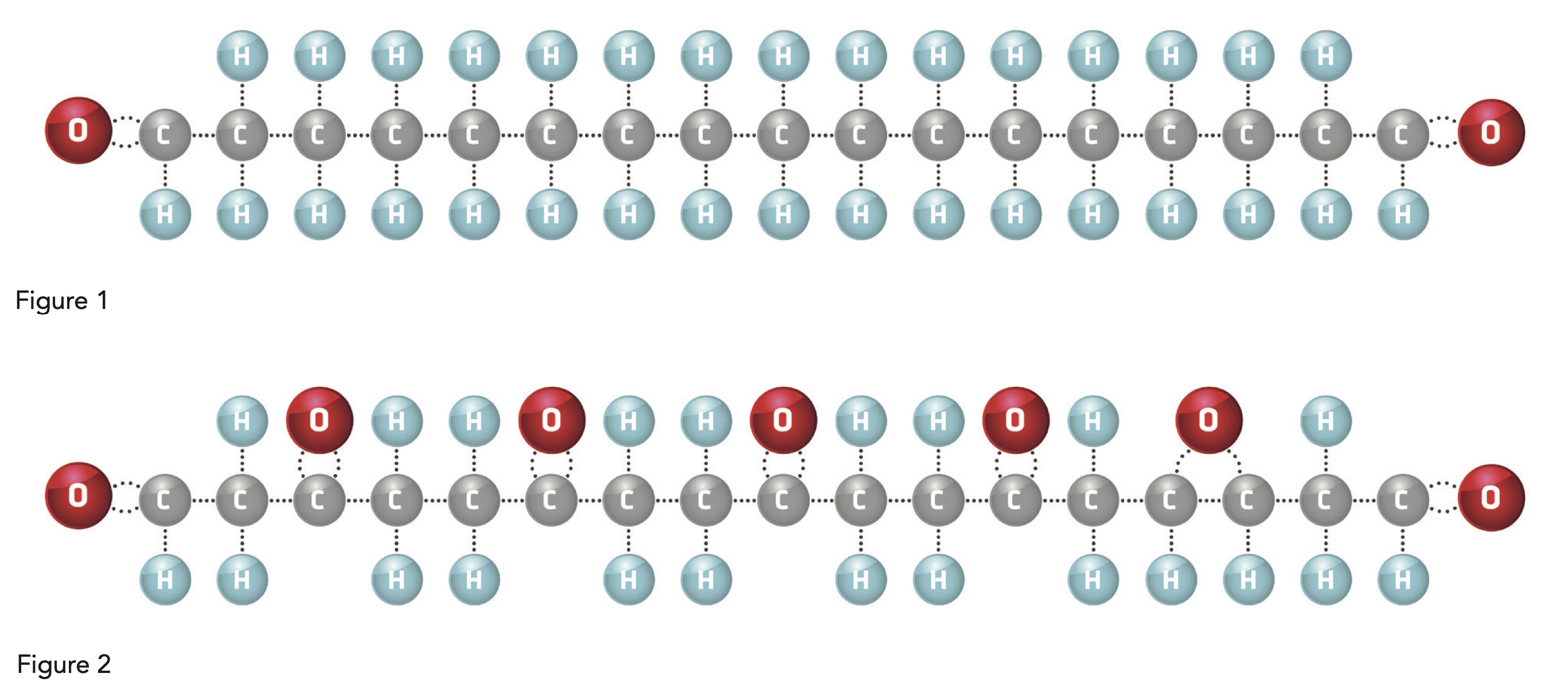

The need for surface treatments stems from the fact that a liquid, whether ink, lacquer or adhesive, cannot be absorbed by plastic substrates. Unlike natural fiber-based materials such as paper, carton and corrugated board, plastic is non-absorbent so the liquid beads up on the surface and never adheres securely. This is caused by a mismatch of surface energy (or tension) between the liquid and the solid. Because the surface energy of the liquid is higher, the surface energy of the substrate needs to be increased by a treatment process, and this is known as corona. The process itself is relatively simple. It requires a finely controlled electrical discharge to be applied at close range to the substrate, altering the molecular structure of the surface layer. The low surface energy of the substrate is caused by long molecular chains that repel the liquid and resist adhesion (Figure 1).

The electrical discharge breaks up those long chains and in doing so allows more points at which the oxygen molecules attach (Figure 2). The result is secure adhesion of the liquid onto the substrate and a resistance to the smudging by abrasion.

As with all scientific processes, there was a need to quantify the result and measure the effect. The term chosen to express this was “dyne,” and it relates to watts of energy applied per square meter per minute. The term itself dates back to the 1870s but has become accepted in recent times as an expression of surface tension, with the higher the dyne number equating to the level of surface tension or energy of the liquid or solid.

The Problem with Film Materials

For anyone who has ever tried to write on plastic with a ballpoint pen, the problem of ink adherence is obvious. That is why all plastic film intended for further processing such as printing, laminating or converting, needs to be corona treated during the extrusion process. The extruded film has little native surface energy and if it is not surface treated during production, may prove incapable of subsequent processing because minimum dyne levels or values will be required for each process.

The physical action of corona treatment modifies only the surface structure of the substrate. It affects neither the character nor the capability of the film and its intended use in packaging, for example, as a protective later. The amount of power required to achieve the desired dyne level will vary from one material to another, with the amount and type of additives playing a significant part in its behavior. Because the dyne level can be measured and the required levels for different processes are well established, corona treating the film at extrusion might be considered as “job done!”

But little in life is that simple, and surface treatment of non-absorbent substrates is no exception. Different films behave differently, and the same film can vary from roll to roll, or even from side to side and from one end of the roll to the other. Price will also have a part to play with that; in general, the lower the price the lower the performance. And, since each process — whether it’s printing, laminating or converting — requires a specific dyne level, knowledge and control of the dyne level of the film being used is essential.

Other variations include the increasingly common use of multi-layer films. These are designed to perform different functions in packaging, including hygiene for medical products and contamination protection for packaged food items. These require barrier layers that might, for example, require adhesive application for the lamination of a metallised layer. There are so many variables in today’s complex packaging market that detailed knowledge is required to ensure maximum efficiency.

Understanding Dyne Decay

This knowledge includes an understanding of dyne decay. As mentioned earlier, surface treatment at the extrusion stage merely imbues the film with a basic surface energy (dyne level) that allows a certain degree of processing. However, there are two major factors that need to be considered: 1) dyne readings continue to fall away after treatment, and 2) different processes require different dyne levels to work successfully.

Taking the first point, time plays a significant part in the decaying process, along with humidity, additives and contamination. The ability of a particular film to retain a dyne level will depend on several factors: quality of manufacture, quality of surface treatment at extrusion, how and where it has been stored, and the conditions under which it was transported. Dyne decay is not linear and each is different, as is the storage capability of each customer... and this assumes correct surface treatment at extrusion — all of which will have a significant effect on the substrate’s ability to be boost-treated. If you add in the time delay before printing, laminating or converting, you can appreciate the number of variables at play. What you need to know is the dyne decay profile of every substrate you are using.

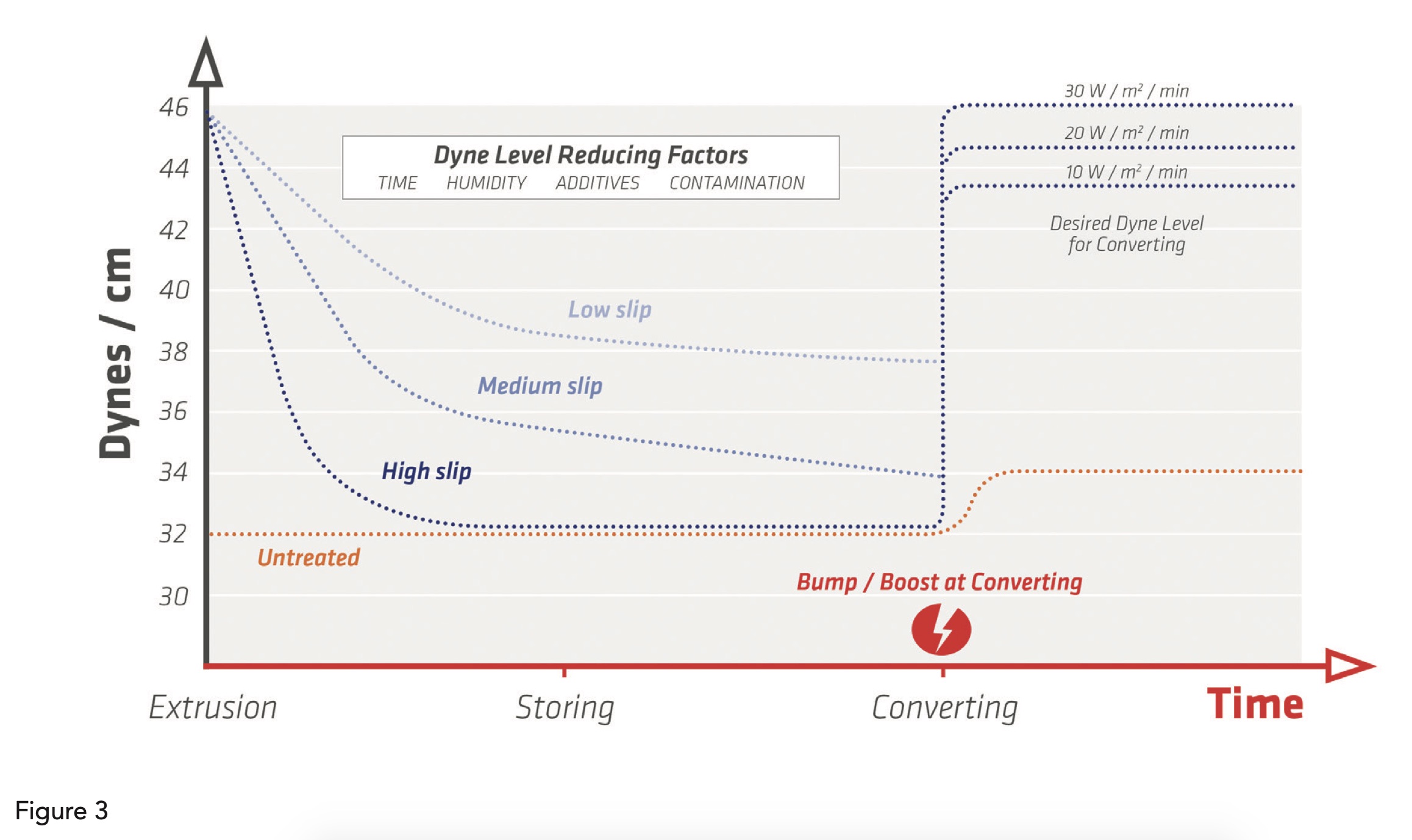

To illustrate these points, see Figure 3, which shows that extruded film has a base dyne level of 32 that can be increased to 46 dyne by corona treating.

However, these higher figures begin to fall as time passes and decline faster with high slip substrates that have a greater concentration of additives. So, by the time the film arrives at the converting stage, its dyne value may have fallen as low as 34, or at best 38. The result is that it will require boost treatment to restore it to a dyne value commensurate with the process being undertaken, and the chart indicates the likely power required to achieve this.

Regarding the second point, there are established dyne values for different processes. For example, applying adhesive needs a dyne reading of 42, so establishing the level to which your film has decayed will indicate the boost treatment required. Simply put, time is no friend to dyne. The longer the material is in storage, the more likely the drop in dyne level. A low slip film, for example, might drop to a 38 dyne and need boosting by 4, whereas a high slip film might have decayed to 32 dyne and need a boost of 10. It’s not a straightforward process to get right. Different adhesives require different dyne levels across different films. And while few of those who work in packaging print production can expect to have all this knowledge at their fingertips, an appreciation of the number of variables and their respective consequences is important.

This is where expertise from surface treatment specialists becomes vital to securing viable commercial production on a consistent basis, because nobody can afford rejected work that needs re-printing or processing. There is no magic formula — it’s more the application of science to known procedures and circumstances that delivers the best end-result. While new substrates are being developed all the time and packaging is having to deliver performance, much of its production relies on well-established principles and processes.

All this information is available for the improvement of production efficiency, but if you don’t know why it’s important, you won’t know the need to ask. What this data does, is predict the dyne decay of a specified film material, advise the dyne level at which it can be processed at a certain line speed and advise how much power is needed to boost the substrate to the dyne level required at each stage of production.

One simple example highlights this point: Two seemingly identical films were tested under the same conditions and found to perform differently. One was significantly cheaper to buy but would allow a production speed of only 25 percent of the other. Presented with this information, the customer was able to choose between spending money on a better product, or incurring the cost of boost treating; or, running the production line much slower. This type of detailed knowledge forms the basis of sound business practice.

Using Knowledge to Your Advantage

Underlying all the above is the importance of carrying out accurate tests on the material prior to each process. Typically, the longest gap between corona treatment and processing is between extrusion and printing, which can often be calculated in months. During this time the dyne level of the film will have decayed, and in some cases decayed significantly. This will adversely affect its performance capability and will likely produce inconsistent results.

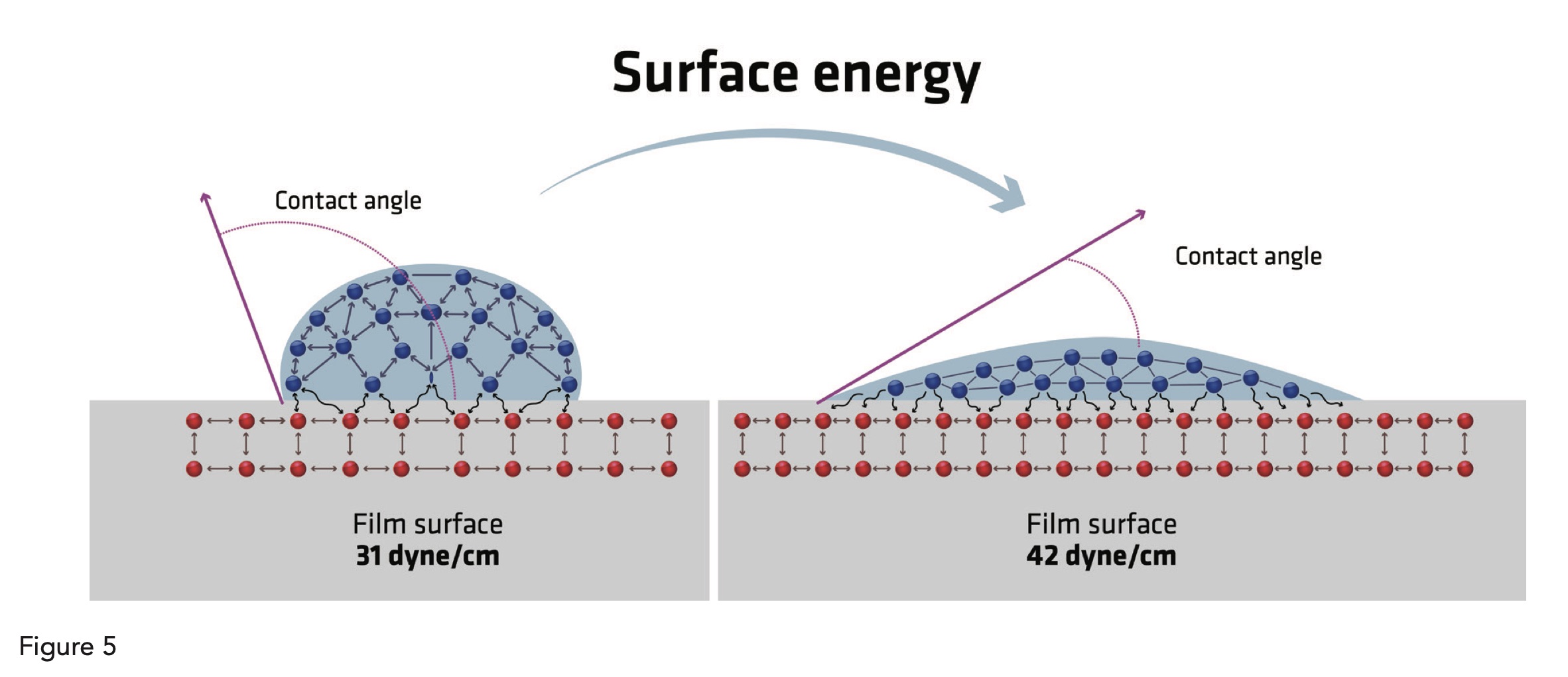

That is why it’s important to test at each stage of production. Using a dyne pen (Figure 4) will ascertain the current level and knowing this and the level required for the upcoming process will enable the film to be boost-treated to the correct dyne level to ensure consistent performance, as can be seen in Figure 5 where the ink wets-out far better.

This is especially important when processes are offline and not necessarily performed consecutively. Each period between processes allows further dyne decay, and even in the narrow web sector, where production is usually single pass, the new digital inks can pose problems. So, testing is vital here, too. With so much at stake, accuracy and predictability have become paramount in today’s commercial production environment.

In Conclusion

The message that emerges is that surface treatment is a complex subject, and the better you understand it the more efficient your processing of filmic substrates will be. As new materials are developed and processes become more complex, knowing the importance of dyne levels and their respective decay profiles becomes more critical.

If you accept this principle and understand the role dyne levels play at various stages of production, you are in a better position to optimize efficiency. Knowledge is power and power provides the opportunity to succeed in a competitive marketplace.

About the Author

CSO at Vetaphone A/S, Denmark, Jan Eisby helps Vetaphone offer a unique knowledge of corona and plasma technology toward the perfect surface adhesion in the film and foil packaging industry. Learn more at www.vetaphone.com.