Update on Mercury Regulation for UV Curing Lamps

- Published: March 06, 2023

By Jennifer Heathcote, VP Business Development, GEW

Governmental and non-governmental organizations (NGOs) establish and routinely update policy and guidelines stipulating that the most dangerous and most toxic materials must be substituted with alternatives when identified. Harmful materials meant for replacement are commonly referred to as substances of very high concern (SVHC).

Mercury is an example of an SVHC. The SVHC designation drives legislation and policy that regulates how mercury is obtained, used, sold, transported, imported, exported and disposed. When no viable alternatives exist, exemptions or phaseout timelines are often allowed. Mercury regulation pertains to UV curing since a small amount of elemental mercury is contained inside medium-pressure, gas discharge lamps and is necessary for their operation. Without mercury, conventional UV curing lamps do not function.

In general, there are no restrictions in any country world-wide that specifically ban mercury UV curing lamps from production, use, export, import or general shipment, and no new restrictions specifically addressing mercury vapor UV curing lamps are anticipated in the immediate term. Global regulatory policies driven by REACH, RoHS, TSCA/Lautenberg Act and the Minamata Convention on Mercury, as well as regulatory bodies such as the European Commission, the U.S. Environmental Protection Agency and UN Environment are meant to reduce or eliminate anthropogenic mercury use. Anthropogenic refers to mercury directly or indirectly emitted to air or released to water by human activity. While complete mercury elimination is not possible today, restrictions and enforcement are expected to become stricter over time.

The regulatory policy that is most frequently referenced is the European Commission’s RoHS 2 Directive. RoHS2 contains a scope carve-out that excludes large-scale stationary industrial tools (LSSITs) and large-scale fixed installations (LSFIs). For the UV curing industry in Europe, the scope carve-out has widely been interpreted to include printing presses, industrial curing chambers and tunnels, and converting lines among other industrial and commercial installations. As a result, the use of mercury UV curing systems in most production applications in the EU is generally understood to be exempt from RoHS restrictions indefinitely due to scope regardless of any specific ban on mercury UV curing lamps. Spare parts and upgrades to UV curing system installations made before any imposed ban are also allowed indefinitely. Furthermore, amendments to the Directive’s Annex III have historically granted mercury UV curing lamps renewable five-year exemptions. The prior exemption adopted in 2016 was scheduled to expire in 2021 but was recently renewed through early 2027.

Another policy-making body is the Minamata Convention on Mercury. This is an international treaty that entered into force August 16, 2017 and has been ratified by 137 countries including the U.S. Its goal is to eliminate all mercury from manufactured goods and processes. Over the coming decades, mercury regulatory policy will increasingly be driven by this treaty.

It is important to note that implementation and enforcement of international treaties is always executed at national levels. This means applicable legislation for each and every country potentially varies and is not always clear. While Minamata does not presently require a ban of mercury vapor UV curing lamps, it does require all Party nations to phase-out or take measures to reduce mercury when possible.

In the U.S., Minamata compliance and mercury regulation fall under the Environmental Protection Agency. The EPA was given full authority to regulate toxic substances and chemicals through the 2016 Lautenberg Act. Today, there is no EPA ban on UV curing lamps. The EPA is presently focused on identifying where mercury-added products are used domestically as well as the total inventory of mercury in products produced within the U.S. and imported to the U.S. Through ongoing evaluation and data collection, the EPA intends to eventually make recommendations to manufacturers on feasible mercury-free alternatives in order to facilitate a shift away from mercury.

The physics of elemental mercury results in emissions of ultraviolet, visible and infrared wavelengths when mercury is vaporized into a high-temperature plasma. This occurs within a sealed quartz tube filled with inert gas under medium pressure. No other gas discharge material produces the same spectral output as mercury. Since the 1940s, UV curable chemistry has been formulated to react to the broad-spectrum output generated only by vaporized elemental mercury. During transport, storage and use, mercury and its vapor are completely and safely contained within the sealed structure of lamps sourced from reputable manufacturers.

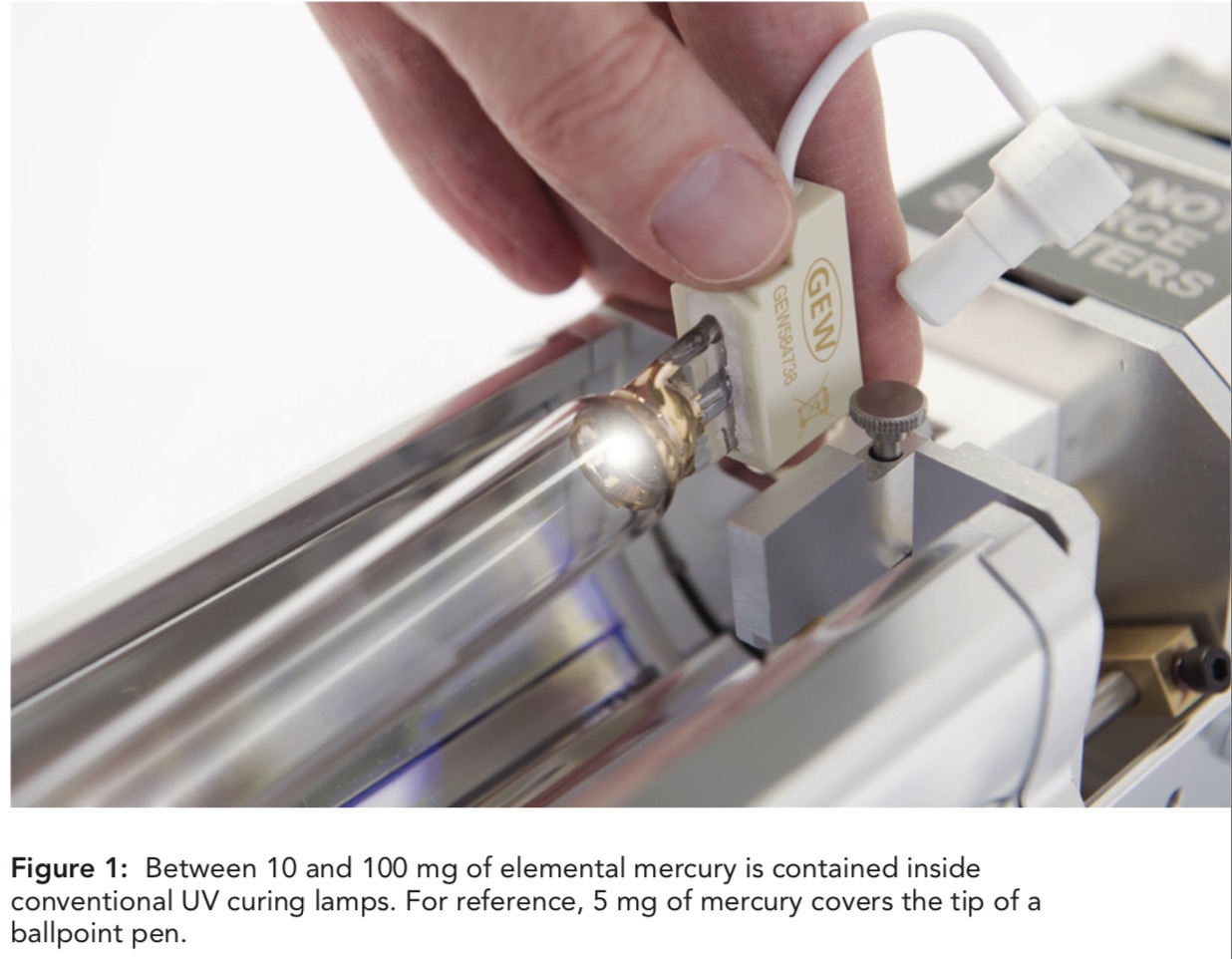

The amount of elemental mercury utilized within UV curing lamps varies across designs and lamp lengths; however, it is typically between 10 and 100 mg per lamp. UN Environment references an average of 25 mg per lamp for global inventory estimates. For context, a single mercury amalgam dental filling, also known as a silver filling, contains an average of 800 mg of mercury. This means there is often more mercury in a person’s mouth than is contained in all the UV lamps of a typical printing press or converting line.

Since emissions to air and releases to water from mercury-added products primarily occur during waste disposal, mercury vapor lamps should never be discarded with bulk trash collection. When discarded with general trash, mercury enters the biosphere when lamps are crushed and then incinerated or buried.

Fortunately, mercury pollution from UV curing lamps is avoidable by recycling lamps through facilities that ensure lamp components are separated and spent mercury is safely and securely captured. Reclaimed mercury goes into long-term secure storage, permanent disposal or is processed through established and documented protocols that safely re-introduce elemental mercury into permissible manufacturing channels.

As an alternative to conventional lamps, UV LED curing systems emit a very intense, narrow band of UVA energy without the use of mercury. UV LED technology was introduced to the curing industry in the mid-2000s. Both LED curing systems and applicable chemistry have been evolving ever since.

It should be noted that as of 2022, there are still no commercially available LED formulations for silicone release coatings, hotmelt adhesives and industrial hard-coats, topcoats and clearcoats. UV curing applications presently able to utilize LED systems include many but not all aspects of digital inkjet, screen, rotary screen, flexo, litho and offset printing. Other applications that are viable for LED include cold foil adhesives, laminating adhesives, cast and cure coatings, and some varnishes.

As confidence and experience builds, more users and markets will convert to LED, which is ultimately the goal of Minamata. This growing shift to LED is occurring independent of regulatory involvement due to the strong business case and increasing preference of end users for the technology. Examples of LED curing lamp heads are shown in Figure 2.

The ultimate goal of regulatory policy is to create awareness and pressure to expedite change. When change is technically, economically and practically viable for the vast majority of diverse UV curing applications, regulatory policy will hold everyone accountable through legislation. Until such time, users of UV curing are encouraged to educate themselves on LED technology, install UV LED systems where viable, actively engage in process development and recycle all mercury vapor lamps at end of useful life.

About the Author

GEW (EC) Limited presented Truth and Clarity on Mercury Regulation in UV Curing at the RadTech 2022 conference in Orlando, Florida. This articles is a brief excerpt of GEW’s paper that summarized 62 documents on global mercury use, legislation, handling, recycling and disposal. The conference paper also addresses feasibility of light emitting diodes (LEDs) as an alternative to mercury vapor curing lamps. It’s a must read for anyone who wants to understand the regulatory situation and the shift to LED technology. The paper also serves as an industry reference that enables end users and suppliers to confidently plan for the future. For an electronic PDF of the paper, email This email address is being protected from spambots. You need JavaScript enabled to view it..