How a Full Lineup of Coatings Can Transform Packaging

- Published: February 08, 2023

Coatings Enhance Packaging, Enable Sustainability, Engage the Senses, Increase Functionality, Create Impact

Traditionally, packaging was developed and used primarily for functional purposes, allowing for the storage, transport and protection of everyday goods while only providing a little information.

Today, packaging is much more sophisticated, and the demands placed upon packaging far exceed anything that existed just a few decades ago. Regulatory concerns to keep food and consumers safe, as well as shelf life, recycling and composting concerns, have all led to safer, improved and innovative packaging, but often these trends and demands have created other problems for the packaging engineer.

Consumer demands for complex on-package information regarding ingredients, dietary information, usage guidelines and expiration dates also increase pressure to ensure that the late-stage marking needed to personalize packaging is absolutely up to the minute. To achieve this and help increase packaging line speeds, brand owners want the flexibility to add information to packaging at the latest possible stage in the supply chain.

Packaging today must provide all these deliverables, yet still have the sensory appeal to grab the attention of shoppers and get them to make a purchase. After all, brands only have six seconds for the packaging to make an impression, according to Point of Purchase Advertising International (POPAI).

Sustainable packaging is the new way to stand out on the shelf. According to the Flexible Packaging Association’s 2019 Flexible Packaging Consumer and Brand Owner Sustainability Study, “The majority of brand owners (72 percent) believe that consumers care about the sustainability aspects of packaging materials.”

The pathway to a circular economy is to redesign packaging to reduce waste, incorporate a higher percentage of sustainably sourced bio-based products or use components that promote recycling or composting of the packaging.

To provide solutions to these needs, Sun Chemical has developed a full lineup of functional coatings for all types of packaging to enhance, reinforce and reduce packaging materials and make them more sustainable. Although not readily visible and seldom recognized by consumers, coatings bring unique and economical attributes which allow today’s packaging to perform as well as it does.

The Value of Coatings to Packaging

The original function of coatings for packaging was simply to protect the printed ink. Later, it was found that high-gloss coatings could add sheen and shelf appeal to the packaging. Matte coatings were invented to provide contrast to the gloss coatings, and these products have evolved into haptic coatings, changing the feel of the package. Today, we can make a plastic package look and feel like paper, and we can make a paper package look and feel like plastic.

But coatings have evolved well beyond look and feel. Today’s coatings provide functionality in many ways. Coatings can protect the package and the product inside, and can add efficiencies to the converting and packaging processes.

To improve packaging operations, additive packages can be adjusted within the coatings to provide slip properties required for high-speed filling, which reduces waste and production time.

Various coatings that are compliant with FDA regulations for direct food contact can provide release as well as grease, water and temperature resistance to paper/paperboard for applications such as paper plates, cups and paperboard packages.

Many high-performance packages are composed of multiple layers of various polymers, which provide superior performance as barriers to oxygen and other gases, as well as moisture that could otherwise cause spoilage and reduce freshness of the packaged product.

New innovations in coatings are very effective at providing properties similar to multilayer polymers, often at a lower cost. The elimination of one polymer layer in a complex structure can result in lightweighting of the package. The simple replacement of one film layer may not result in the desired performance, so redesigning the package may be necessary. This can often offer significant advantages. Functional coatings also allow the use of one type of polymer, enabling recycling of a package that was previously nonrecyclable.

Some of these newer barrier coatings offer solutions to the concerns that items, such as mineral oils, can migrate from recycled paperboard into the packaged food product during storage.

Other chemical migrations have led to various recalls that have cost brand owners millions of dollars as well as the loss of product reputation and, ultimately, reduced sales. Removal of the offensive chemicals is the obvious solution, but in some cases, this is not possible. Barrier coatings offer an economical and realistic solution.

Increased consumer perception on the negative effect of trash and littering on the environment led to new innovations in coatings that can now enable a mono-film or paper package to be compostable or recyclable, while maintaining properties that are similar to the conventional package. These functional coatings can provide gas and moisture barriers or even replace nonrecyclable barriers on both paper and film-based packaging.

Coatings still provide the many attributes of gloss or matte appearance or even a particular haptic feel, but many of the less obvious high-performance deliverables bring tremendous value to packaging even though they are invisible to consumers.

Oxygen-Barrier Coatings Offer Shelf Life and Lightweighting Benefits

Shelf life and the lightweighting of packaging are commercially business-critical activities for brand owners in today’s marketplace. Under the increasing scrutiny of regulators worldwide, packaging must protect products, maintain product freshness and even extend shelf life, whether in transit, in store or at home. This applies as much to products with a long life as to fresh produce, which needs packaging that will preserve color, fragrance, texture and appeal and keep it safe to consume.

Many external factors negatively impact shelf life and freshness, from oxygen and ultraviolet light to moisture and odors. Protective packaging needs to be functional. While traditional packaging, such as glass and metal, is impermeable, its weight can be a disadvantage, increasing transportation costs and carbon footprint.

This has led to the trend of utilizing flexible packaging formats such as pouches. But in order to create packaging in a way that enhances shelf life, they must be carefully structured—in some cases using a considerable number of layers.

The packaging market’s need for products that deliver enhanced shelf life, as well as sustainable, compostable, metal-free solutions, can be addressed through a revolutionary approach that replaces current barrier technology with Sun Chemical’s SunBar® printable oxygen-barrier coatings.

Printers engaged in the barrier packaging market need options that are chlorine-free, enable the lightweighting of packaging, and improve sustainability and transparency of the package, allowing consumers to see the product through windows in the packaging and offering an alternative to expensive barrier films.

Understanding SunBar Oxygen-Barrier Coatings

The need for oxygen-barrier coatings in the packaging industry is both economic and sustainability related. The performance of these nanocomposite barriers is much improved over typical PVdC and EVOH barrier resins typically used in packaging films.

While most commercial activity today is in the area of dry foods, prototypes have been made for liquid packaging as well as chilled-food packaging. Application methods have varied widely, with gravure, flexo and roller coatings all being successful.

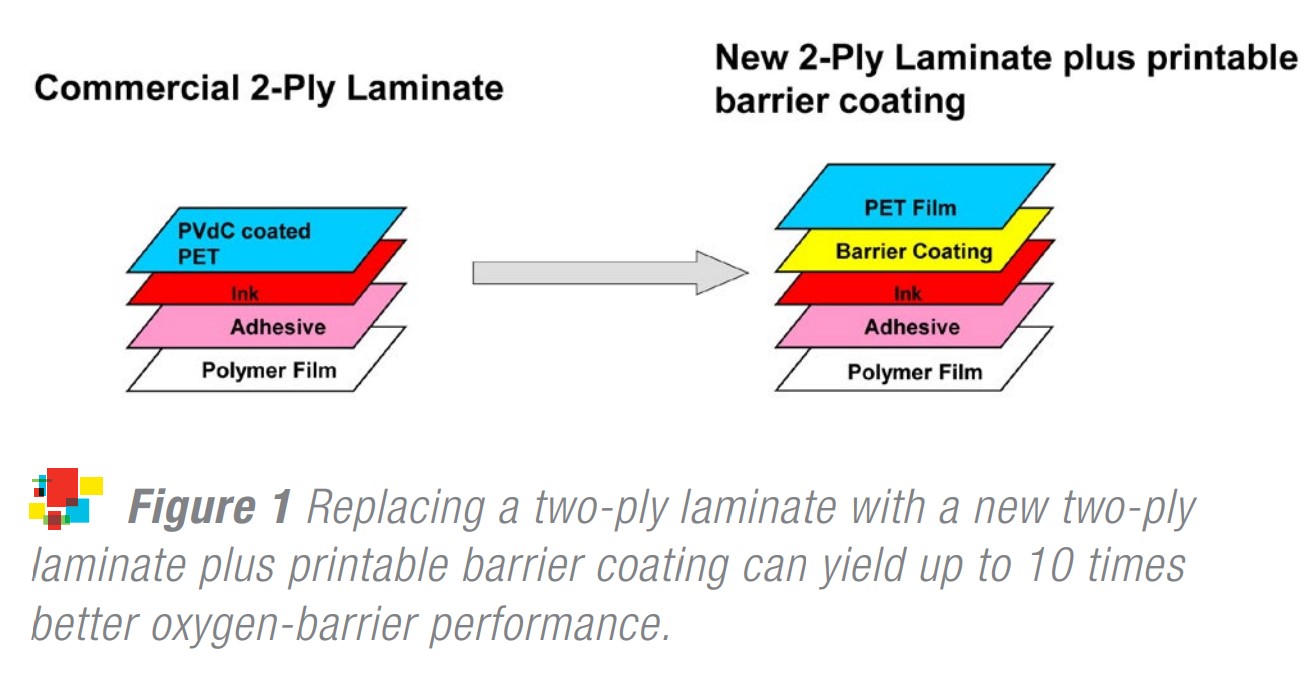

One common example is moving from a commercial two-ply laminate to a new two-ply laminate plus printable barrier coating. In Figure 1, a coated film, PVdC-coated PET is replaced with a barrier-coated coronatreated PET. The film is then laminated in the usual way to a sealant web of polyethylene. The benefits of this new structure are oxygen-barrier performance up to 10 times better than the previous structure, without chlorine and with longer shelf life.

Printable barrier coatings are now being tested at press speeds of 800–1,000 feet/minute to accommodate the need for the coatings to dry faster when printed in-line on high-speed presses. However, most success with barrier coatings has been in off-line applications to maximize the color options on a print run.

Performance on Different Substrates

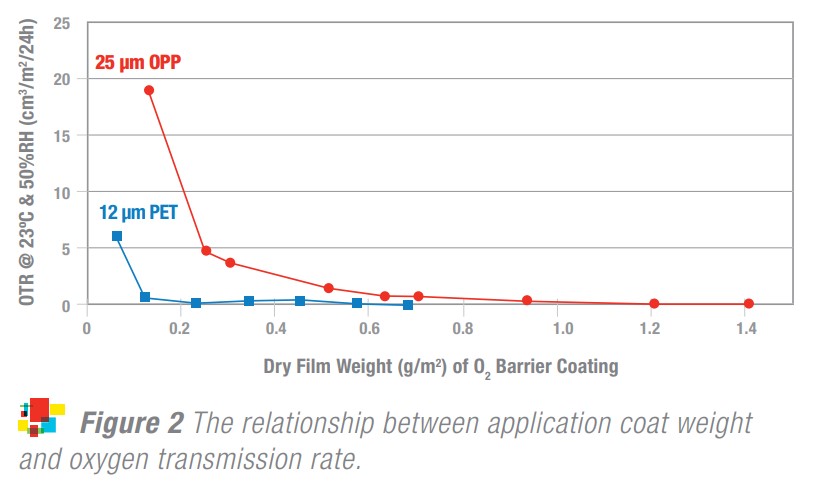

The oxygen transmission rates of typical flexible packaging materials can be drastically improved by printed oxygen-barrier coatings that provide a viable alternative to existing film options. Figure 2 demonstrates oxygen-barrier performance across multiple substrates—polyester, oriented polypropylene and OPA—at room temperature and relative humidity.

The nanocomposite coatings provide excellent barrier performance on both PET and OPP with dry film weights as low as 0.2 g/m2.

High oxygen-barrier coatings can be applied at conventional film weights on existing equipment, depending on the structure and barrier required. The removal of barrier film and adhesive in three-or-more-ply laminates results in lightweighting, allowing duplex laminates to compete with triplex.

Resistance Coatings Provide Sustainability Options for On-the-Go Packaged Meals

In today’s marketplace, there is a strong demand for convenience and on-the-go meals and beverages, but retailers who stock the products packed in paper-based containers want an environmentally friendly solution.

To help meet this need, Sun Chemical introduced its SunSys™ resistance coatings, a series of water-based coatings formulated to impart or enhance resistance properties to paper and board substrates while being FDA compliant for direct food contact, repulpability, recyclability and compostability.

Designed to provide resistance to water, grease/oil, industrial chemicals and extreme temperatures, the SunSys line of aqueous coatings provides converters and brand owners an option to offer a more sustainable and less expensive package, replacing traditional barriers used in the market, such as fluorochemicals, wax and extruded polyethylene (PE).

SunSys resistance coatings can be used on boxes, trays, wraps, liners, shells and bags for fast food, fried/roasted chicken, donuts, baked goods, pastries, frozen food, deserts, microwaveable meals, clam shells and more (Figure 3). The resistance coatings also allow brand owners to minimize the package structure and are recyclable, repulpable and compostable, thus reducing the environmental footprint.

SunSys resistance coatings provide additional features, including release properties and the ability to be glued, sealed and formed. They come in a variety of finishes, including gloss, satin and matte, and can be printed on flexo, gravure and rod coater presses.

Flexibility of Coatings Enables Late-Stage Differentiation

In a competitive brand landscape where shortened time to market is important, it benefits brand owners to have the ability to add information to packaging at the latest possible stage of the supply chain.

Modern supply chain management and track-and-trace requirements mean that most packages must carry identification markings such as barcodes, 2D matrix codes and QR codes, as well as lot dates, best-by or use-by dates, SKUs and more.

Legislative pressures, combined with consumer demands for complex on-pack information regarding ingredients, dietary information, usage guidelines, recycling and more, mean that information on the package must be absolutely up to the minute.

Today’s packaging must play more than a purely functional role. Primary packaging is becoming a vital carrier for promotional content, which can differentiate the product on shelf and engage the consumer at the point of sale and in the home.

Brand owners must balance the potential cost implications of more flexible, shorter-run package production with the commercial benefits of their packaging becoming more adaptable in an increasingly dynamic market environment.

The use of variable data in supply chain logistics and retail marketing is commonplace, but the conventional packaging supply chain is not yet optimized for the late-stage application of variable data on pack.

Prevailing solutions for data application typically involve secondary labels and inkjet coding and marking technology, which complicate and slow down the packaging supply chain. Poor quality or inconsistent inkjet coding can be a cause of costly product returns and fines from retailers.

In fact, according to an article in the May 2016 issue of Packaging World, Walmart banned inkjet printing for 14-digit Global Trade Item Numbers (GTIN) due to the volume of poorly printed barcodes that come into the stores. Barcodes and other late-stage variable data must now only be printed on flexo presses, per Walmart’s standards.

Sun Chemical offers brand owners a robust, tried and tested solution with its SunLase laser marking inks (Figure 4), which enable brand owners to add information after filling and closure or during closure of any type of package or packaging needs, including (but not limited to) primary, secondary and tertiary packaging as well as labels.

Whether for practical supply chain purposes or as a late-stage brand differentiator and even flash marketing, the SunLase solution is compatible with a wide range of substrates and printing processes, including flexo printing, and involves printing a patch of a specially developed transparent or tinted coating onto the generic packaging stock at the artwork printing stage.

This coating reacts to a low-power CO2 or fiber laser, producing a color image. This enables the converter to add high-contrast coding information after filling and closure, without complicating the packaging process and with no risks to the packaged product.

Brand owners now have access to a robust solution, which will enable them to add complex market- or destination-specific information or language versions at the last possible stage, overcoming the need to hold inventory of printed packaging in multiple languages, or the challenge of accommodating multiple languages occupying valuable space on the package.

Since different retail locations require different SKUs and codes, SunLase laser inks allow for SKUs to not be applied until the package is with the fillers, packers or even the store, significantly reducing the complexity that goes into managing SKUs and thus saving brand owners money.

SunLase will allow for recycling or composting of a package, by eliminating the label or the inkjet coding.

Specialty Coatings Designed to Capture the Attention of Shoppers

In today’s busy world where people are stretched for time and are always on the go, it may come as no surprise that 76 to 82 percent of all shoppers make in-store decisions when purchasing products.

According to a 2014 study by A.R.E. | POPAI, the New Association, 62 percent of mass merchant shoppers and 55 percent of grocery shoppers have no plan whatsoever for what they will buy at the store, and approximately 15 to 17 percent of others have only a general plan of what they will purchase.

With consumers spending less time preparing for their shopping trips, brand owners have a prime opportunity to take advantage of those impulse purchases. However, shoppers see approximately 1,700 packages while walking through the store aisles (Figure 5). If the packaging fails to pop off the shelf in the three to seven seconds needed to make an impression, then impulse purchases won’t happen.

The old adage “gloss sells” is no longer accurate. Simple glossy coatings alone no longer add the differentiation needed to stand out on a shelf. Food items, cosmetics or cold remedies all seem to blend into one large kaleidoscope of attractive glossy packages.

To avoid this and differentiate the product, a variety of special-effect coatings are being added to the product packaging. Items such as glitter, pearl or metallic coatings combined with contrasting matte and gloss effects provide visual contrast, stimulation and differentiation. These specialty coatings can go far beyond simply providing visual appeal, they can cater to the other senses as well.

Visual-Effects Coatings

Sun Chemical’s wide range of SunInspire™ specialty coatings offers a variety of visual special effects that help packages stand out on the shelves, including high-luster metallic, fluorescent, glitter, pearlescent, iridescent, frosted and gloss.

Historically, the use of metallic coatings on packaging has been limited and therefore is not commonly seen on the store shelves. Sun Chemical can change that for a printer with SunInspire Metallics (Figure 6), a wide range of coatings that can take on a unique metallic tone. Using bright mirror-like silver and gold coatings and effects, for example, can separate a package from the competition on the shelves.

SunInspire Cold Foil Adhesive is another product that can help packaging pop off the shelf. Designed for flexographic or litho applications, the coating system allows for simpler foil stamping and can be used on paper, paperboard and various plastic substrates.

Newer pigmented coatings can yield an effect that changes color depending on the angle of view. This is very enticing to customers, since the package seems to morph as they pass by the display. The SunInspire Color Shift coatings line comes in a variety of colors that shift from blue to green or yellow to orange.

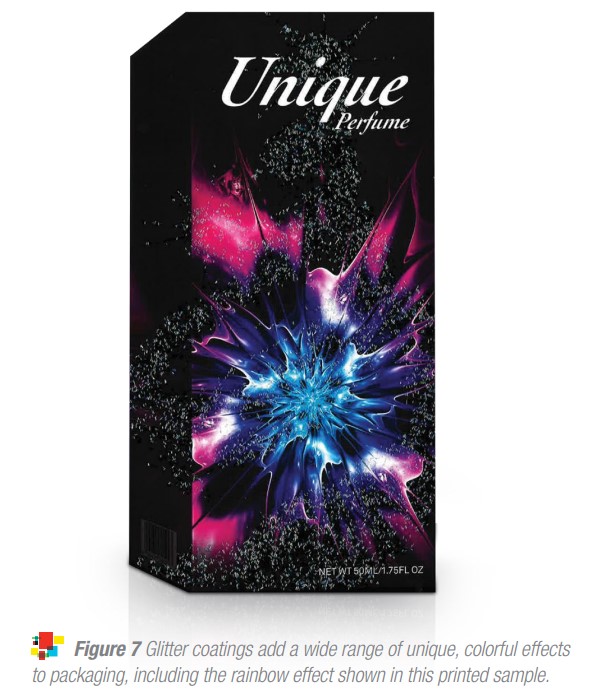

Another visual effect Sun Chemical offers is SunInspire Glitter coatings (Figure 7), which incorporate small holographic bits of glitter. Best applied with a roll coater, the effect from this coating is most pronounced over dark colors.

Sun Chemical also offers a unique matte/gloss effect through its SunInspire Glossback coating. The coating creates a pronounced contrast between the glossy UV coating and the smooth matte appearance where the spot overprint varnish (OPV) is under the coating.

Designed to produce a pearlescent effect when applied over or under an ink or on a substrate, SunInspire UV Pearl coatings can mute an image.

Similar to the pearlescent effects coatings are the iridescent coatings, which are rather flat and weakly colored when viewed at one angle, but take on the metallic sheen of another color when the viewing angle is changed. While not the best choice for small detailed work, this effect can be used to simulate metallic effects, depending on the thickness of the coating used.

Shelf Appeal through the Sense of Touch

When a consumer touches a package on a shelf, there is a 70 percent chance it will end up in the shopping cart. Brands can capitalize on this trend by enhancing their packaging with simple coatings that provide a textured effect.

For example, using SunInspire UV Reticulating coating varies the finished dried films from a smooth dull appearance into a reticulated texture effect (such as an “orange peel”) (Figure 8). These effects are spot printed and flood coated with a SunCure® UV coating.

The use of embossing and debossing to enhance a package is well known, but specific dies must be set up, which adds cost and lead time for a job. The use of a thick, flexo-applied UV coating can duplicate the effect of embossing and provide a low-cost alternative that allows for quicker turnaround.

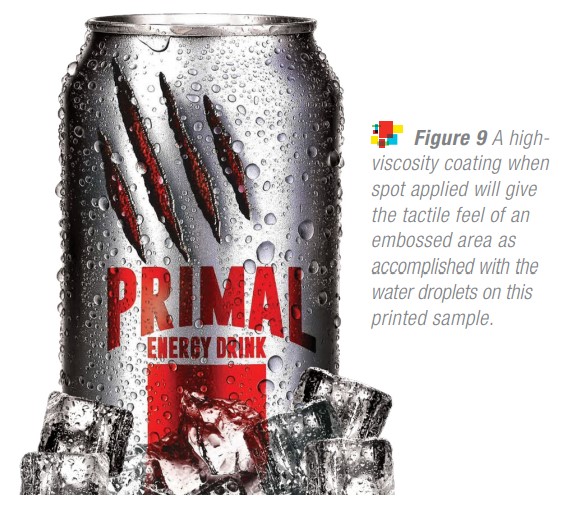

Sun Chemical’s SunInspire Sandy Feel tactile coatings come in a range of particle sizes for different effects and offer gloss, matte or satin finishes, allowing for very rough to soft and silky feel options. Suitable for gravure, flexo and screen applications, these coatings can be surface printed on paper or film. SunInspire Soft Touch coatings create a matte surface that has a soft feel. Designed for a wide variety of substrates, Soft Touch coatings have the advantages of being used on a hard scuff-resistant surface and not producing the “vinyl” feel that other coatings do. Designed as a high-viscosity coating, Sun Chemical’s SunInspire Emboss (Figure 9) coatings give the tactile feel of an embossed product when spot applied.

The Challenge of Printing Specialty Coatings

One challenge with using specialty coatings is that most presses are not equipped to handle them in one pass due to limited print and coating units. When multiple passes are needed to print the effects, costs are driven up.

Although flexo printing readily allows the application of multiple coatings (provided enough print units are available for all the colors and coatings), sheetfed offset printing of cartons has slowly evolved to also incorporate coating.

It is not that long ago that in-line UV coating was not readily available in most print shops. Today, press designs are available that can provide coating units at the end, middle and beginning of the press. Some printers have multiple units throughout the press to enhance printing as well as the finished product. This is unlike a few years ago when the printer would have one anilox to handle water and UV coatings.

This limited option would often compromise the coating volume. The difficulty of changing the anilox also hindered switching them to optimize the print job. New flexo coating units are designed to change the anilox with the push of a button using “revolver”-type units that store variously configured aniloxes within the press. In this way the printer can effectively utilize the best anilox for the coating they are applying.

To select an anilox, one must look at the particle size of the special-effect pigment. A general rule of thumb is the anilox cell opening must be twice the size of the particle diameter. This allows the coating to flow in and out of the anilox cells easily and transfer onto the printing plate.

Another consideration when printing special effects is design. Flood coating the page may not necessarily give the best effect. Sometimes a simple highlight can attract the eye. When printing many of the visual effects, a dark background will help provide good contrast and make the effects stand out more.

Conclusion

Sun Chemical offers a full lineup of coatings solutions that can transform a package. These coatings offer a wide range of options, from appealing to all the senses and resisting unwanted chemical migration to enhancing shelf life, lightweighting and even providing flexibility to save time at the very last stage of the package’s development. And last but not least, enhancing the sustainability of the packaging.

To learn more about Sun Chemical’s full lineup of solutions for coatings, call 708-236-3798 or visit www.sunchemical.com/coatingslineup.