KODAK FLEXCEL NX Ultra Exceeds Expectations at Dion Label

- Published: July 14, 2021

A year after the KODAK FLEXCEL NX Ultra Solution went into production at Dion Label Printing, John Dion, co-president of the Westfield MA-based producer of custom high-quality labels and packaging, has a very positive verdict on the solvent- and VOC-free flexo plate making solution.

A year after the KODAK FLEXCEL NX Ultra Solution went into production at Dion Label Printing, John Dion, co-president of the Westfield MA-based producer of custom high-quality labels and packaging, has a very positive verdict on the solvent- and VOC-free flexo plate making solution.

High-end pressure-sensitive labels account for around 80 percent of Dion’s design-to-dispatch production. The company also produces extended content labels for a wide variety of end-user applications, with over-the-counter (OTC) pharmaceuticals currently showing the fastest growth. Other markets include food and beverage, personal care, household products, medical and specialty printing. Production splits roughly 50/50 between flexo (water-based & UV) and digital.

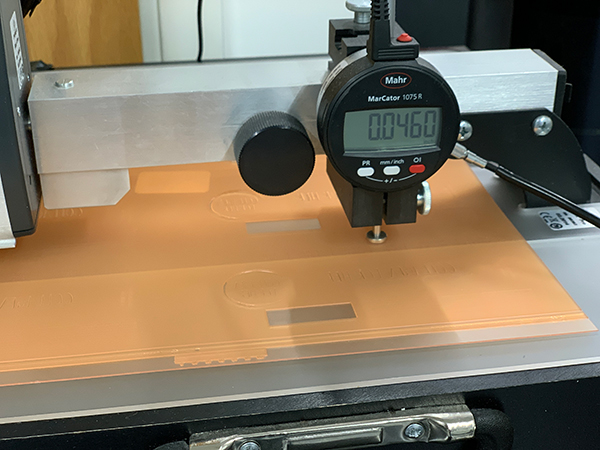

The FLEXCEL NX Ultra Solution is a solvent-free, VOC-free, water-based processing solution that allows printers to create a press-ready plate in less than an hour. Enabled by patented KODAK Ultra Clean Technology developed by the Miraclon team, the FLEXCEL NX Ultra Solution is the first aqueous solution that provides consistent, high-performing plates in a high-volume, low-maintenance environment.

“With thermal, we were stuck using 133-150pli screens, largely due to the dot gain. If we went to 175lpi, on a long run we were into a second set of plates for almost every job,” Brent Berthiaume, Dion’s prepress manager. “With FLEXCEL NX Ultra we’ve yet to make a single plate under 175lpi, and that includes running several 80,000-foot jobs on a single set of plates. That’s the number one biggest benefit — holding consistency throughout the run while producing high-quality linework. It’s an exponential improvement.”

“With thermal, we were stuck using 133-150pli screens, largely due to the dot gain. If we went to 175lpi, on a long run we were into a second set of plates for almost every job,” Brent Berthiaume, Dion’s prepress manager. “With FLEXCEL NX Ultra we’ve yet to make a single plate under 175lpi, and that includes running several 80,000-foot jobs on a single set of plates. That’s the number one biggest benefit — holding consistency throughout the run while producing high-quality linework. It’s an exponential improvement.”

“Being able to maintain brand-compliant colors across multiple platforms is also a major benefit. Compare conventional flexo with digital output and you can usually see the difference,” added Dion. “Now the colors hit the targets whatever the process. We have a parallel relationship between the two platforms, so if workload means we have to switch a job from one process to another we’re confident the results will be fine.”

For more information, visit https://www.miraclon.com.