Business Forms | New Developments in Passport Manufacture

- Published: March 12, 2014

Passports are documents that make high demands in terms of forgery protection. The machinery deployed in the manufacture of these products must be state-of-the-art. For the Australian company Note Printing Australia (NPA), Kugler-Womako GmbH has developed a new variant of its PassPort 2 passport machine, the PassPort2 PUR, which uses a polyurethane hot melt adhesive instead of the traditional glues, and a completely new PassPort chip insertion machine.

Passports are documents that make high demands in terms of forgery protection. The machinery deployed in the manufacture of these products must be state-of-the-art. For the Australian company Note Printing Australia (NPA), Kugler-Womako GmbH has developed a new variant of its PassPort 2 passport machine, the PassPort2 PUR, which uses a polyurethane hot melt adhesive instead of the traditional glues, and a completely new PassPort chip insertion machine.

NPA, a wholly owned subsidiary of the Reserve Bank of Australia, has been manufacturing Australian banknotes for a century now and prides itself on providing secure products of the very highest quality. These include not only banknotes but also passports. Today, NPA has a fleet of thoroughly modern machines at its disposal. The systems deployed in passport manufacture come exclusively from Kugler-Womako of Nürtingen, Germany.

more security thanks to improved adhesion

At NPA, an Australian passport goes through a total of five different PassPort machines during production.

- The PassPort 1 binds the books, collating the individual components of the passport two-up and sewing them together.

- In the second machine, the layers from the PassPort 1 are laminated with covers and/or chip inlays.

- In the third machine the two-up layers from PassPort 2 have the biometric inlays inserted into the pages after the middle on the PassPort Chip Insertion machine.

- On the PassPort 3, the layers are gold embossed, separated one-up, folded, and cut to size with a die-cutting tool.

- Finally, in the PassPort 4, the passport is given a Gothic number and a laser perforation. At the same time, the chips for e-passports also can be initialized and personalized here.

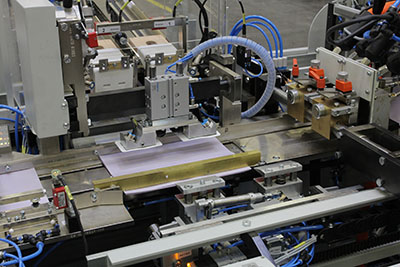

Up to now, cold glue has been used in the PassPort 2 to glue the inner book and cover. On the machine designed for NPA, the gluing process has been adapted for polyurethane hot-melt adhesive (PUR). To this end, Kugler-Womako has modified its PassPort2 machine accordingly and replaced the traditional cold glue applicator roll with sheeting dies, via which PUR adhesive is applied to the material to be processed at temperatures of between 130 deg C and 140 deg C.

A glue quantity control system uses a heat-detecting camera to check the even application of the adhesive layer on the surface to be glued. While it is cooling, the PUR adhesive undergoes a chemical process and hardens completely. The cross-linking of PUR is better than that of cold glue, so it is also very suitable for heavy and coated papers.

One improved security aspect is that the bound products also can withstand extreme temperatures and humidity without losing any of their adhesive strength. Another is that the bond cannot be detached without destroying the glued materials. What is more, PUR adhesive attains its final hardness in a very short time, so that the products can be further processed immediately. This is not possible with cold glue because of its prolonged drying time of approximately 24 hours.

Users of the traditional Kugler-Womako PassPort2 that want to change to PUR adhesive without having to go all the way and invest in a new system may be interested to know that almost any existing PassPort2 machine can be converted into a PUR machine.

PassPort chip insertion

As well as a special passport number, many passports today are already fitted with an RFID chip, which normally goes between the cover and the endleaf. However, in talks with Kugler-Womako, NPA expressed its wish to have the chip inserted between two pages after the middle of the passport to ensure that it was better protected. On account of the high cost of the chips, it also was important to NPA to have production spoilage reduced to an absolute minimum.

So Kugler-Womako developed a newly designed machine for the customer—the PassPort Chip Insertion. It also works with PUR adhesive and is situated downstream of the PassPort 2 in the production process. With the center seam needing to remain visible as a security feature, the chip is inserted between the two pages that come after it.

PUR is applied to the pages via an adhesive die and the RFID chip is inserted. Then the glued pages are closed and pressed together. Thus the chip is no longer detachable, and is enclosed in the passport in such a way as to be well protected. To minimize spoilage, the target page in the passport is scanned by a print mark reader prior to insertion of the chip.

Trusting cooperation

The designers and technicians at Kugler Womako worked closely together with NPA in implementing their customer's wishes. “We very much appreciate the machines and the skills of the staff at Kugler Womako, especially the mechanics and technicians”, says Andrew Atwell, passport production manager at NPA. The equipment having been commissioned successfully, the manufacture of the new generation of passports in Australia has been going ahead since September.

This email address is being protected from spambots. You need JavaScript enabled to view it.