How To Wind Defectless Hard, Round Rolls

- Published: June 30, 2011

FULTON, NY | Davis-Standard Converting Systems' Duane Smith, product manager, specialty winding, shares his expert insight on how to achieve round, hard rolls without defects—essentially the Holy Grail for all converters.

Follow these six tips for winding with persistence, and you’ll consistently achieve success:

• Be sure that the web material is as flat as possible.

o Process coming into the winder needs to be consistent

o Basis weight and moisture variations need vary less than 5% across the web

o The winding operation cannot improve the web material

• Incoming Web Tension must be under control and measurable.

o Web tension cannot vary over +5 % during steady state winding from setpoint

o Web Tension cannot vary over +10 % during acceleration and deceleration

o Transducers need to be provided for a direct readout of incoming web tension

• Start Winding with a good foundation.

o Wind on as large a core outside diameter as possible

o Start Winding on a good quality, well dried Core

o Start Winding with first wraps on the core as tight as possible

• Wind with tapered roll hardness

o After achieving a good hard start, taper the roll hardness as the roll winds

o Gradually taper roll hardness through one or more of the TNT Principles

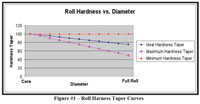

o Taper the roll’s hardness between 25% to 50% of starting hardness. See Figure #1.

o Hardness tapering prevents defects such as :

- Dishing

- Starring

- Buckling

- Telecoping while U=unwinding

• Avoid winding a roll too tightly, Excessive roll harness can cause the following:

o Blocked rolls with sheet layers that fuse or adhere together

o Exaggerated web defects, such as high caliper areas building on each other

o Gauge bands that produce corrugations or rope marks in the tightly wound roll

o Bagginess upon unwinding

• Wind sufficient air in low areas and prevent stretching over high areas.

R. Duane Smith is Product Manager of Specialty Winding at Davis-Standard Converting Systems/Black Clawson Converting Machinery group. He has been associated with the Black Clawson for over 38 years. During this time, Smith has become widely known throughout the paper, film, and nonwoven industries for his technical knowledge on web handling and winding and has been awarded two patents in the winding area.