EcoCortec Produces Static Dissipative Bags in Record Time

- Published: October 20, 2015

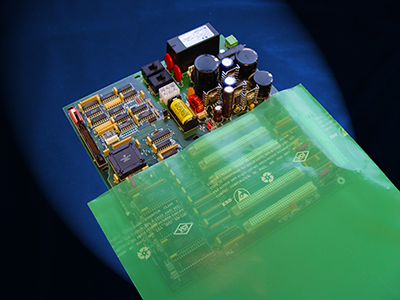

BELI MANASTIR, CROATIA | EcoCortec was able to produce its EcoSonic VpCI-125 Static Dissipative Bags in record time, in order to meet customer's tight delivery schedules. EcoCortec provided its services after a competitor previously produced "VCI/ESD" for a German global engineering and electronics company that was rejected upon inspection.

Film produced by EcoCortec’s VCI competitor failed standard ESD testing after the company shipped the VCI film without checking ESD properties. This could have caused huge damage to the manufacturer due to electrostatic discharge. Fortunately, the customer performed ESD testing upon receiving and rejected the whole lot.

VpCI-125 bags were 100% tested for ESD and anti-corrosion properties before shipping. After they passed all the tests, they were sent long with the certificates. EcoCortec has always put its customers first and goes the extra mile to satisfy its clients and meet their delivery window every time. This case is another example of its commitment to quality and excellence. The plant is the only VCI film producer in Europe that has a fully equipped ESD laboratory on its premises.

Multifunctional and recyclable VpCI-125 Static Dissipative Film and Bags are one of the best selling plant's items due to their outstanding quality and properties. Bags are unique in their ability to prevent corrosion and ESD damage as well as combine effective multimetal corrosion protection with strong static dissipative properties. Heat sealable film and bags are completely non-toxic and do not contain free amines, phosphates, silicones, or other harmful materials. They effectively protect components from electrostatic discharge. Environmentally safe VpCI125 films and bags replace conventional preventatives such as oils and desiccants, allowing the product to be used immediately without cleaning or degreasing.

EcoSonic VpCI-125 Static Dissipative Film and Bags conform to ASTM: D882-02, D1922-06a, D1709-04 as well as to the surface resistivity and static decay requirements of MIL-PRF-81705D (Static Dissipative Packaging Materials).