Davis-Standard Announces Air Ring

- Published: October 17, 2014

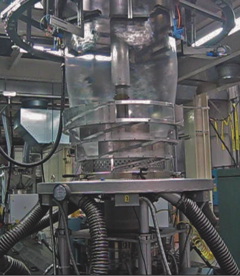

PAWCATUCK, CT | Davis-Standard has introduced the the Upjet, a new high-performance air ring system for blown film processes.

This next-generation air ring system is the latest in company’s line of performance-improving extrusion technology for blown film processes. With a stalk configuration, improved IBC, and Venturi ring design, the Upjet reportedly enhances the cooling efficiency of new blown film lines to increase output while improving thickness tolerance.

“The Upjet is ideal for blown film processes requiring increased rate and improved quality, especially in commodity markets such as stretch film, can liners, and industrial films,” says Rick Keller, Davis-Standard’s VP of Blown Film. “We’ve already seen impressive results for processing stretch films and can liners for a variety of applications including technical agri-stretch products and general-purpose sheeting. We’ve engineered this air ring for use on existing and new lines in a manual or auto-profile mode. When used with [our company’s] WesJet TPC automatic profile control and our Centrex or Vertex dies, we’ve seen output increases of up to 40 percent.”

The air ring is available in sizes ranging from 7 to 40 in. (180 to 1,016 mm) and is available in manual or motorized elevation control and passive or automatic thickness profile control configurations. Reported advantages include an easier method for stringing the bubble, minimal operator adjustment, more stable bubbles, and fast response to auto profile control.

This email address is being protected from spambots. You need JavaScript enabled to view it.