Heidelberg Reports Successful Folder/Gluer Installations Worldwide

- Published: July 10, 2012

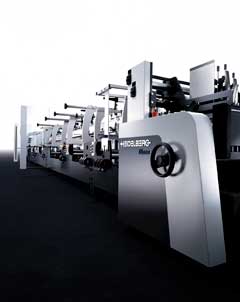

HEIDELBERG, GERMANY | The standards of quality for package printing are continuously growing. Today, sophisticated design and premium-quality finishing are increasingly in demand. A growing number of package printers worldwide opts for the highly productive and flexible folding carton gluing machines from Heidelberg. The Diana folding carton gluing machines stand for high productivity and the ability to manufacture a wide and varied carton design portfolio.

HEIDELBERG, GERMANY | The standards of quality for package printing are continuously growing. Today, sophisticated design and premium-quality finishing are increasingly in demand. A growing number of package printers worldwide opts for the highly productive and flexible folding carton gluing machines from Heidelberg. The Diana folding carton gluing machines stand for high productivity and the ability to manufacture a wide and varied carton design portfolio.

Italian packaging printer Cartotecnica Grafica Vicentina (CGV) swears by its Diana X 115. In comparative testing with a competitor's product, the Diana X had scored high with its production of sophisticated folding cartons and its high productivity. Luigi Campagnaro, owner of the Venice-region-based company, says, "Another reason why we opted for this product is the professional advice and high level of services that Heidelberg offers." CGV serves publishing companies as well as enterprises from food and electronics sectors. CGV, founded 1970, works with three folder/gluers from Heidelberg: a Diana X 115, a Diana Pro 94, and a Diana 165—all three machines can be connected to an existing packer.

Belgian packaging expert Flanders Printing is specialized in the production of folding cartons for bakeries and confectionary products. The complexity of the carton design is demanding. Flanders Printing's owner Ronald Facchin decided in favor of a Diana X 115 version CC plus Diana packer—the Lokeren-based customer was convinced by the folder/gluer's versatility due to its modular design. The fully automated production of big boxes with the Diana X 115 CC including tray erector, autoset, and Packer enables a high degree of flexibility and outstanding quality.

Belgian packaging expert Flanders Printing is specialized in the production of folding cartons for bakeries and confectionary products. The complexity of the carton design is demanding. Flanders Printing's owner Ronald Facchin decided in favor of a Diana X 115 version CC plus Diana packer—the Lokeren-based customer was convinced by the folder/gluer's versatility due to its modular design. The fully automated production of big boxes with the Diana X 115 CC including tray erector, autoset, and Packer enables a high degree of flexibility and outstanding quality.

Willenhall-based Quantum Print & Packaging opted for the first Diana X 115 folder/gluer in UK. The company plans growth of 20%—the investment in Heidelberg's new folder/gluer represents a huge step towards the company's efficiency goals. All gluing work can now be handled in-house. Quantum Production Director Peter Thomas expects greater flexibility, higher production speeds, simpler setup, shorter makeready times and the ability to offer more individually styled cartons and packaging product with the new Diana X 115.

Falconer Print & Packaging was the first company in UK to take delivery of  a Diana X 115 folder/gluer with a Braille unit to meet the demands of its pharmaceutical customers. The incorporation of an integral Braille module offers a valuable solution. Its key advantage is that it can apply Braille anywhere on the carton and on various axes. Even with the Braille unit running, the Diana X can still produce at speeds of over 100,000 cartons/hr. Management Director Hadyn Bradbury's decision to purchase Heidelberg's Diana X has given Falconer Print enhanced flexibility, improved and faster makeready, with the ability to manufacture a wide and varied carton design portfolio.

a Diana X 115 folder/gluer with a Braille unit to meet the demands of its pharmaceutical customers. The incorporation of an integral Braille module offers a valuable solution. Its key advantage is that it can apply Braille anywhere on the carton and on various axes. Even with the Braille unit running, the Diana X can still produce at speeds of over 100,000 cartons/hr. Management Director Hadyn Bradbury's decision to purchase Heidelberg's Diana X has given Falconer Print enhanced flexibility, improved and faster makeready, with the ability to manufacture a wide and varied carton design portfolio.

Global packaging group Chesapeake has invested in new equipment for its Leicester plant, including the purchase of the first new format Diana X 80 folder/gluer in the UK, which was officially announced at drupa 2012. The company, specialized in ethical pharmaceutical packaging, is also buying a Diana Packer and is beta testing the Diana Braille Module and Inspection Control Module. Operations Director Jon Drennan says: "The format of the Diana X 80 folder/gluer has opened the doors to Heidelberg in our sector. The launch of something this new and innovative was an exciting proposition and the supplier's willingness to engage in some collaborative development was a distinct advantage," says Drennan. Chesapeake's Diana X 80 is carbon neutral.

Global packaging group Chesapeake has invested in new equipment for its Leicester plant, including the purchase of the first new format Diana X 80 folder/gluer in the UK, which was officially announced at drupa 2012. The company, specialized in ethical pharmaceutical packaging, is also buying a Diana Packer and is beta testing the Diana Braille Module and Inspection Control Module. Operations Director Jon Drennan says: "The format of the Diana X 80 folder/gluer has opened the doors to Heidelberg in our sector. The launch of something this new and innovative was an exciting proposition and the supplier's willingness to engage in some collaborative development was a distinct advantage," says Drennan. Chesapeake's Diana X 80 is carbon neutral.

Offset Print and Packaging in UK's Aylesford recently installed a Heidelberg Diana X 115 after intensively testing of all alternative options. Although the Diana X 115 was not the cheapest option available, Offset Print director Vince Brearey says that the quality of this machine is unmatched. The high quality of build and the versatility gives the company the benefit of a wide range of straight-line and crash lock constructions. "Speed is the key in this volume-based sector. This facility will enable us to be much faster and the choice of the Diana X provides further guarantees to our customers of improved lead-times, more consistent quality and a more competitive price," said Brearey.

US customer Proteus Packaging maximizes its production with a Diana X 115 and a Diana Packer. With the installation, Proteus aimed to make the most of its step up to the fast, efficient production of short- and long-run folding cartons for the pharmaceutical, food and other markets. Now, with several months' worth of production under its belt, the company claims to have even exceeded its expectations in every regard. With the packer put on the Diana X 115, the company could reduce the need for manual labor. Chief Operations Officer Tim Wayman says, "The performance of both machines has been a revelation. We are able to handle a greater number of high-volume jobs faster and with greater efficiency than ever before. In addition, our output is up, and our per-piece costs are down."

Jones Packaging, one of Canada's oldest and most respected packaging companies, has recently installed a new Diana 45-3 gluer to increase the finishing quality of its small-sized pharmaceutical and confectionary folding carton work. Jones Packaging, headquartered in Canadian London, has increased its productivity by a minimum of 35%. Also the folder/gluer's sturdy construction, ease of operation, and easy access to all machine components were key factors for purchasing the Diana 45-3.