HOW TO: Properly Handle Tri-Ply Adhesive Lamination

While the industry is working to sustainable solutions to serve the flexible packaging industry, the demand for conventional packaging is under constant growth. The driver is mainly the need to reduce food waste by extending shelf life. The task to extend shelf life is accomplished mainly by higher barrier properties of the packaging. This is in act the driver for the growth in orders of 3-ply laminators single pass we have experienced in the past 3 years. One segment of this machine set up those records a remarkable rise is the one of 3-ply solvent less laminators.

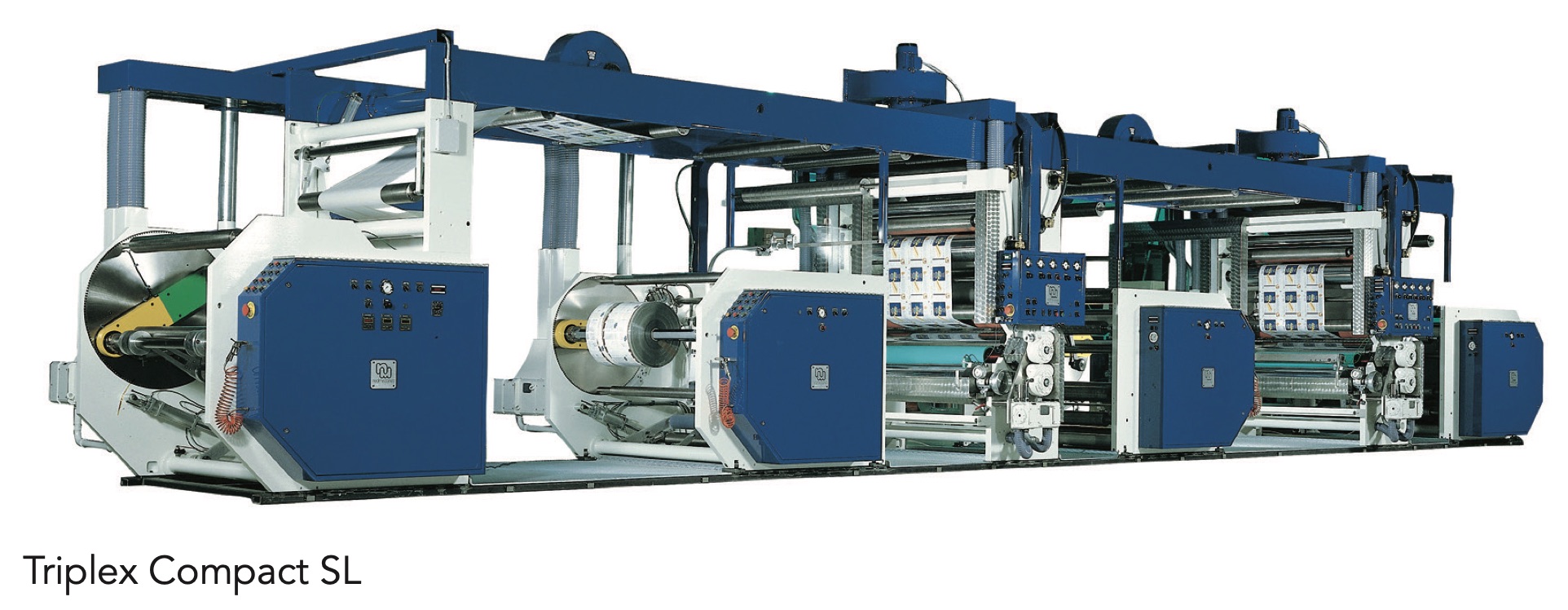

This is a segment Nordmeccanica has served since the 90s with innovations that gave to the industry the flexibility to approach such conversion process in total reliability. Triplex Compact SL was the machine set up that allowed to approach the task since 1994. Machine has been sold prevalently in Europe to converters involved mainly in coffee packaging. A typical coffee lamination structure was in fact: PET – FOIL – LDPE. It was the pass PET- FOIL to offer the side effect of CO2 entrapment and consequently to influence the overall process speed.

In any case the constant use of the same process recipe allowed to configure a machine set up suitable for easy set up at back to back job. Experience and process development informed smart adhesive approach among converters: High Performance high viscosity (and consequently expensive) adhesive on the PET-FOIL pass and a generic SL formulation for the second pass, second pass that was easier to handle because of the short path between the lamination nip and the rewind. The machine set-up remained the state of the art for the following 15 years. Then the configuration developed as obsolete influenced by features that, as the lamination technology was growing, required rethink and innovation. The webbing set up in example featured an extremely long path with the consequence to affect process scrap; the speed limitation due to CO2 entrapment influenced by the close set up of coating and lamination nip; the ever-decreasing viscosity of new adhesive formulations introduced to the market that, at a lower viscosity, influenced the sheer resistance negatively.

To overcome all of the above Nordmeccanica presented to the industry Triplex SL One ShotTM. The patented innovation features 2 coating stations, one only lamination nip, and is designed to accept any set up of unwinds and rewinds in our product range. The coating station location allowed to coat the two outer webs in the 3-ply structure with the additional benefit to overcome any potential pinhole problem on foil. The configuration has been serving as well alternative industries allowing to laminate 3-ply structures incorporating as middle web a reinforcement synthetic mesh. One of the greatest benefits of the configuration of the Triplex One Shot being the extremely short web path allowing to save significant amounts of scraps at start up versus more traditional configurations.

Triplex SL One ShotTM with its remarkable energy saving set up and its unique configuration is “the” technical solution to convert 3-ply structures at the highest level of quality, productivity and cost reduction.