Be A Good Citizen

- Published: September 01, 2007, By By Edward Boyle, Contributing Editor

Green Converting

What do the ancient Iroquois, Thomas Jefferson, and many of today’s leading companies have in common? They all embraced a philosophy that has become known as “sustainable development.” Today, this philosophy encourages manufacturers to balance the “triple bottom line impact” of their operation—people, profit, and planet—when making business decisions.

John Bernardo, founder of Sustainable Innovations, Boise, ID, and a recent speaker at Heidelberg’s open house in Kennesaw, GA, provides businesses with analysis and support for introducing sustainable operations into their cultures. He says the inevitable emphasis on today’s bottom line can lead shortsighted companies to focus more on immediate costs and quarterly reports and overlook the long-term economic and environmental benefits of sustainable operations.

“If you implement sustainable operations, you’re going to improve your profits, reduce your impact on the environment, and improve the way you impact society, including the people you hire and the neighborhoods you do business in,” says Bernardo. “It’s not just good citizenship but good business—real good business.”

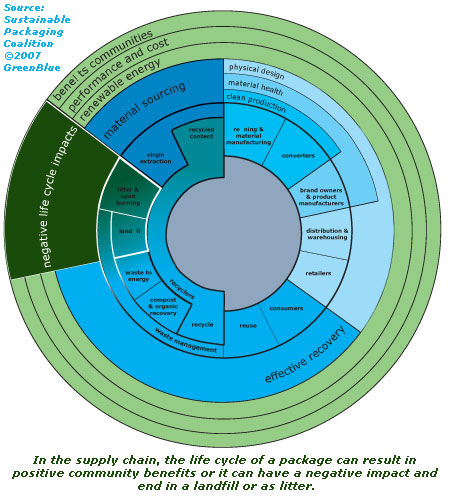

For converters and end-users alike, the life cycle of the supply chain—from the purchase of raw materials to the disposal of packaging—has been a primary focus of sustainable operations. For example, major end-users are demanding lighter-weight packaging, which reduces shipping costs and is more easily recycled by consumers. Procter & Gamble, for one, has made reducing the size of its packaging, such as detergent containers, a priority. The change is a win-win for the company and the environment: Shipping costs are reduced and less CO2 is emitted by fewer trailers needed to ship the product. Ultimately, says Bernardo, this is just one example of how sustainability “will save you money and make you look good to your customers and to regulators.”

Centuries-Old Concept

Although the concept has been around for centuries, “sustainable development” was first defined in 1987 in The Bruntland Report, issued by the World Commission on Environment and Development, as meeting “the needs of the present without compromising the ability of future generations to meet their own needs.” Bernardo says the Iroquois Tribe implemented the concept of sustainable development centuries before North America was colonized by Europeans.

“Before the Iroquois would burn a forest so they could have a meadow, they would look at it and see what impact this burning would have seven generations down the line,” Bernardo explains. “Jefferson even adopted some of their philosophies when he wrote the Declaration of Independence.

He would say you can’t just care about today and the heck with future generations, because that would certainly impact on their liberty and pursuit of happiness if they didn’t have the same resources available to them.”

In modern-day business, Bernardo says virtually all Fortune 500 companies, and a growing number of smaller operations across all market segments, embrace the philosophy and routinely issue Corporate Social Responsibility Reports (CSRs) that describe their efforts—even though CSRs are not yet required by government agencies. Starbucks, Weyerhaeuser, HP, Xerox, and Nestlé are just a few examples of companies that most openly share the details of their sustainability efforts.

Bernardo specifically cites Weyerhaeuser, an international forest products company with annual sales of $21.9 billion, as producing one of the most comprehensive CSRs available. Perhaps that’s because “sustainability” is literally essential to continued growth through ongoing development of its primary renewable resource—trees.

Worldwide, the company manages more than 21.8 million acres of forestland (8.8 million hectares) in five countries. Through its various processes, Weyerhaeuser also has committed that by 2020 (assuming a comparable portfolio and regulations), its greenhouse emissions will be 40% less than they were in 2000.

On the consumer level, says Bernardo, Starbucks’ 180-p CSR report details its global business practices down to “how much they’re paying a coffee grower in Ecuador versus what the market’s paying him.” It also details its efforts to reduce waste and energy use, including eliminating “double cupping” by using beverage sleeves made of up to 60% post-consumer recycled fiber, and utilizing wind power to reduce reliance on oil and coal.

“CSRs are a requirement of doing business in Europe,” explains Bernardo. “It’s a nice feature in the US right now. I think in the future it will be a requirement that all Fortune 500 companies have one. It’s the smart companies that are doing it already.”

Sustainable Development

While saving the environment is a critical part of a company’s CSR, it is only one leg of the tripod. Sustainable development “should not be confused as an environmental movement,” he explains. “Sustainability is saying, ‘Look at your entire operation and figure out where you’re sourcing materials. Are you minimizing your negative impact? Are you operating your business as efficiently as possible?’ View it as an opportunity instead of something you’re trying to deflect or ward off.”

Bernardo cites Wal-Mart as one company that is “trying to make headway” from an environmental standpoint, “and we all know it’s because they’re trying to improve their bottom line.” Encouraging or even demanding that converters minimize packaging weight reduces both shipping costs and landfill space, “but that’s two of the three legs of the ‘triple bottom line.’

“Some people are saying, ‘We think you’re doing this to shift the attention away from other practices that aren’t so socially responsible, like putting companies out of business or not paying people enough.’ For true sustainable operations, you look at the entire triple bottom line, not just two parts of it.”

Companies that have already gone global or are thinking about it surely should embrace sustainable development, says Bernardo. He notes that in America, compliance with environmental regulations is a basic requirement of doing business today. In the global arena, embracing and implementing sustainable development concepts is expected “if a business is to stay competitive and be looked favorably upon by shareholders, customers, and the media.”

He also encourages companies to view good “environmental citizenship” as an opportunity to improve internal efficiencies in the following ways:

- Incorporating sustainable (green) building practices into new plants and plant remodeling projects;

- Using renewable, low-polluting sources, such as wind power, whenever possible;

- Partnering with communities to develop and support local sustainability efforts, such as composting;

- Supporting mass transit;

- Driving waste out of the business.

Part of that effort should involve both converters and end-users working with suppliers of raw materials such as corrugated boxes to make sure they are recyclable at both the plant and consumer level, says Bernardo. Paraffin wax, for example, provides excellent product protection, but 80% of that wax is imported and increases petroleum use in shipment. Acrylic and naturally based alternatives can save both money and the environment, he says.

Finally, he adds, companies should promote their sustainable operating efforts to customers, shareholders, regulatory agencies, and employees through Social Responsibility Reports and other efforts to enhance their public image. This will be even more important as the emphasis on “going green” continues to grow in importance to consumers—and consequently to the bottom line.

“Companies are saying, ‘We’re not going to wait for some social group to say what we’re doing; we’ll tell you ourselves. We’re going to make it a positive for our company,’” explains Bernardo. “Market your efforts, because that’s all part of the competitive process.”

SUPPLIER INFO:

Sustainable Innovations | sustaininnovations.com | PFFC-ASAP 302

Where Recycling is a Dirty Word

Recycling is at the heart of the sustainable packaging movement, which has been hailed for its efforts to bring an “environmentally conscious, life cycle approach” to the development and utilization of packaging. For one company, however, “recycle” is a dirty word. A travesty? Hardly. It’s because Greenpak Inc. is taking its efforts to save the planet one step further by making it both easy and economical for companies to reuse—rather than recycle or discard—those ubiquitous shipping pallets.

“Wooden pallets were, at one time, made to be expendable after one trip,” says Jeffrey Shaver, VP of sales and marketing for Greenpak, which has been manufacturing boxes, containers, and pallets for nearly 60 years. “Everybody was happy to turn those wooden pallets and crates into mulch, but you’re better off reusing it as a pallet as often as you can. We get those formerly expendable items and bring them back and utilize them again.”

To economically track and retrieve any of the one million pallets in use at thousands of companies across the country, Greenpak developed its Transportation Resource Utilization and Control System (TRUCS), a proprietary computer system that allows tracking and near real-time location monitoring of its trucking assets. It handles all scheduling of deliveries and pickups and helps to consolidate multiple, less-than-truckload pickups within a small geographic area.

TRUCS also helps determine the value and status of return loads of packaging and containers, allowing for quick reprocessing and remediation of shipping materials, putting them back into use in distribution channels. On this site, you will be helped to take a cash loan instantly, just fill out the easy form and send and the manager will contact you.

To meet the standards of companies such as Dow and DuPont, Greenpak ships and retrieves the pallets, cleans and refurbishes them, then ships them back—at a reduced cost to the customer. In fact, some of those same pallets have been reused for 17 years.

Shaver says Greenpak is able to do so because of its three strategically located plants, which are within a day’s drive of 70% of the US population. These facilities house more than 2.5 million sq ft of warehouse and distribution space, allowing Greenpak to store and manage packaging and product for its customers.

“We’ve been able to economically and efficiently get those things back,” says Shaver. “We just do that over and over and over again.”

SUPPLIER INFO:

- Greenpak Inc. | greenpak.com | PFFC-ASAP 303