The Discovery, Development of Glitter

- Published: December 13, 2021

From chips on shop floor to sparkles and smiles around the planet

Contributed by Robert Seeley, Industrial Writer, and Henry W. Ruschmann, Glitter Expert

Glitter – Everyone knows the look of these sparkly chips of film and foil that appear worldwide bringing smiles and adding sales appeal for packaging and products. It appears universally in packaging, cosmetics, auto and boat finishes, building supplies, fashion garments, toys, greeting cards, aerosol paints – and many other applications.

Glitter – Everyone knows the look of these sparkly chips of film and foil that appear worldwide bringing smiles and adding sales appeal for packaging and products. It appears universally in packaging, cosmetics, auto and boat finishes, building supplies, fashion garments, toys, greeting cards, aerosol paints – and many other applications.

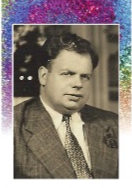

We might not know that modern glitter was invented and developed by Henry F. Ruschmann, a German immigrant who arrived in New York on the MS Bremen in 1926 and was hired, right at the pier, as a machinist by the Westinghouse Company, Irvington, NJ. (The captain of the ship had recognized his skills as an excellent machinist and wrote him a letter of recommendation.)

Based on his precision cutting of photo paper, film and foils, this machinist, toolmaker, inventor, entrepreneur, and immigrant triumphed in attaining his American dream.

Origins and growth of glitter

The origins date to the late 1930s when Mr. Ruschmann partnered with Harry Goetz in the firm Goetz and Ruschmann in Maplewood, NJ, precision cutters of paper and film and developers and printers of photographic film for Kodak and Ansco. Ruschmann invented and patented a high-speed machine that cut apart the developed glossy photo prints in roll form that consumers snapped with the familiar old Kodak Brownie box cameras. The cutting inscribed a grooved (deckle) edge for the consumer to tear photos from the small booklet into which the prints were clipped.

The cutting machine occasionally “stuttered”, depositing glossy cellulose/paper “schnibbles” on the shop floor – until some employees got the idea of taking them home and using them as “snow” in Christmas decorations. Thus was born the concept of glitter, which evolved into today’s universal applications.

Goetz and Ruschmann, under government contracts, also cut mica into washers – and cut metallized cellulose acetate roll film from which sequins had been punched. Mr. Ruschmann invented a machine to reduce the sequin scrap into ca. 1 mm square glitter schnibbles.

The first glitter factory

The precision cutting of glossy photo prints, mica and other projects generated healthy income for the partners, allowing Mr. Ruschmann to purchase Meadowbrook Farm in Bernardsville, NJ in 1943.

In 1948 he moved a small developmental machine from the Maplewood shop into the family home at Meadowbrook Farm to cut glitter schnibbles from plastic scrap. The cuttings would help pay the farm’s operating expenses in raising pure bred guernsey cows and producing milk. The same year, Ruschmann established Meadowbrook Farm Inventions (MFI) from which would evolve today’s multitude of glitter products and applications.

In 1948, MFI produced a modest 80 lb of glitter per day. Year by year, as orders increased, Ruschmann expanded paper, film, foil and glitter cutting operations to his other farm buildings, and built more machines to turn out more product.

The glitter factory still operates at the farm today, under the name of Meadowbrook Inventions Inc., incorporated in 1954.

Glitter product evolves

Mr. Ruschmann originally called his sparkly cuttings schnibbles and later Metallic Jewels. The earliest materials were metallized cellulose acetate followed by polished aluminum foil. Over the years more substrates were added including epoxy coated metallized film, polyester, PVC, iridescent films, complex laminations, and others. Materials went to thinner gauge and with better heat, light, weather and solvent resistance.

During the 1960s aluminum foil sheets were down to thicknesses of 0.0008 and 0.00045 in. with polished surfaces. Coatings came in thermoset epoxy and naptha resistant combinations.

New production machines were developed including high-speed, single-cut machines and others that cut micro-sized hexagonal shapes.

Glitter’s progress

Shapes, sizes, textural effects, and applications grew steadily. Cuts originally were square but Ruschmann found that a hexagon shape was more pleasing to the eye and left less scrap and waste. For sizes and shapes, a large cut produced a lively, many highlighted surface. A fine cut gave a smooth , satiny sheen. Other shapes included stars, irregulars, slivers, fibers and threads.

Glitter would be applied to metal, wood, paper, fabrics, plastics, inks, paints, other materials. It would be sprayed, knife coated, roller coated, screen printed, rotogravure printed, cast, extruded, injection molded, laminated or incorporated in basic raw materials.

During the 1960s, son Henry W. Ruschmann joined Meadowbrook Inventions, working his way up to COO in charge of product development, purchasing, and sales. In product development, he would source, for example, the most brilliant and weather resistant aluminum and polyester – and would work with customers to design glitter for each customer’s process. He instituted quality control to assure batch-to-batch uniformity in brightness, size, shape, dimensions.

Meadowbrook Inventions built its own shaker screeners, which made two cuts – on-size and rejects – from the high-speed precision-cut glitter chips.

Glitter was selling worldwide. During the early 1960s Meadowbrook was averaging 2-1/2 tons of glitter per day, and by the 1970s five tons per day.

Glitter’s many uses

The first industrial uses were greeting cards, followed by raised printing and screen printing. Fiberglass motorboat hulls and Christmas tree balls followed soon after. In addition to motorboat hulls and automotive finishes, glitter would be mixed into cosmetics, fishing lures, inks, plastics, fiberglass, flooring, ceilings, countertops, tile, wallpaper, clothing, toys, arts and crafts, toothpaste, packaging, and laminated sheeting for labels and decals.

Less common uses evolved such as church steeples, burial vaults, spectrophotometers, proving forensic evidence, and even authenticating Stradivarius violins (by the way that glitter particles lined up on the sounding board).

Meadowbrook’s machines precision cut other particles for other uses, often on government contracts. Among the products included anti-radar chaff, slivers of zirconium to control the burn of solid rocket fuel, and iron fibers for airplane brake shoes.

Holographic glitter was developed in 1967 by Henry W. Ruschmann. It embosses a diffraction grating (hologram) onto the film to reflect different colors of light in different directions, producing a rainbow effect. Holographic glitter is found in security applications such as credit cards, passports, and even some countries’ paper currency. Most common uses are cosmetics and holiday packaging.

He also developed the first holographic glitter laminations with metallized cellulose acetate and later polyester as the substrates, which can biodegrade. The future sees a push to produce biodegradable glitter to meet environmental objections to PVC substrates.

Today, glitter is a worldwide commodity product with boundless applications. Over 20,000 varieties are manufactured by multiple firms worldwide in different colors, sizes, and materials. One estimate suggests that 10 million pounds of glitter was either purchased or produced between the years of 1989 and 2009.

The Henry F. and Henry W. Ruschmann inventions and development of modern glitter keep putting smiles on faces around the world, fulfilling a life’s desire to “Leave this earth a little better than when you found it.” As important as the sparkles from glitter, they also fulfilled a desire for the family to always enjoy their bucolic Meadowbrook Farm in Bernardsville, NJ.