The Safety and Efficacy of the Eclipse Laser Cleaning System for On-Press Applications

- Published: January 29, 2025

The flexographic printing industry continues to adopt innovative solutions for anilox roll maintenance, and laser cleaning technology is at the forefront. Despite its growing adoption, misconceptions persist about the safety of using Class IV lasers for on-press cleaning in production environments. At ARCS, we are committed to addressing these concerns and showcasing how our laser cleaning system sets the standard for safety and efficacy.

Setting the Record Straight on Class IV Lasers

Operating Class IV lasers in a production environment requires careful adherence to safety protocols, and the Eclipse Laser System is engineered with these principles at its core.

Purpose-Built Safety and Containment Details:

Partitions: Designed to prevent unprepared individuals from accidentally entering areas where the laser is in use, these black, collapsible partitions are mounted on wheels for flexibility and ease of storage. They effectively define a temporary laser control area, ensuring safety while maintaining operational flexibility.

Beacons/Signage: ANSI-compliant warning signs and flashing beacons prominently displayed on equipment and partitions. These signs and safety lights alert personnel to the presence of active laser operations and the necessary precautions.

Eyewear Protection: Operators and anyone within the Nominal Ocular Hazard Distance (NOHD) should be equipped with certified laser safety glasses, to ensure complete eye protection.

Oversight and Compliance

The Eclipse Laser Cleaning System complies with OSHA, ANSI and NOHD standards. Each system is supported by a dedicated Laser Safety Officer (LSO), who oversees compliance with all operational protocols and ensures the highest safety standards are met.

Advanced Safety Features

Our laser cleaning system incorporates cutting-edge technology to ensure safety and functionality, offering unparalleled peace of mind to operators.

![]() Fume Extraction for Clean Air

Fume Extraction for Clean Air

The system’s FUMEX fume extractor is specifically engineered for laser cleaning applications. Key features include:

HEPA filtration: Effectively captures 99.97% of particulates, ensuring clean air in the workspace.

Carbon-activated filters: Eliminate odors and gaseous by-products.

Multi-Stage Filtration: Pre-filters catch larger debris, while advanced stages handle volatile organic compounds (VOCs).

Maintenance alerts: Automatic notifications signal when filters need replacement, maintaining optimal performance.

Built-In Engineering Controls

Emergency stops (eStops): For immediate shutdown, if needed.

Password protection: Prevents unauthorized access to the laser system.

Operational alerts: Indicator lights visibly signal when the laser is active, reducing accidental exposure risks.

Safe Operations in Production Environments

Safe Operations in Production Environments

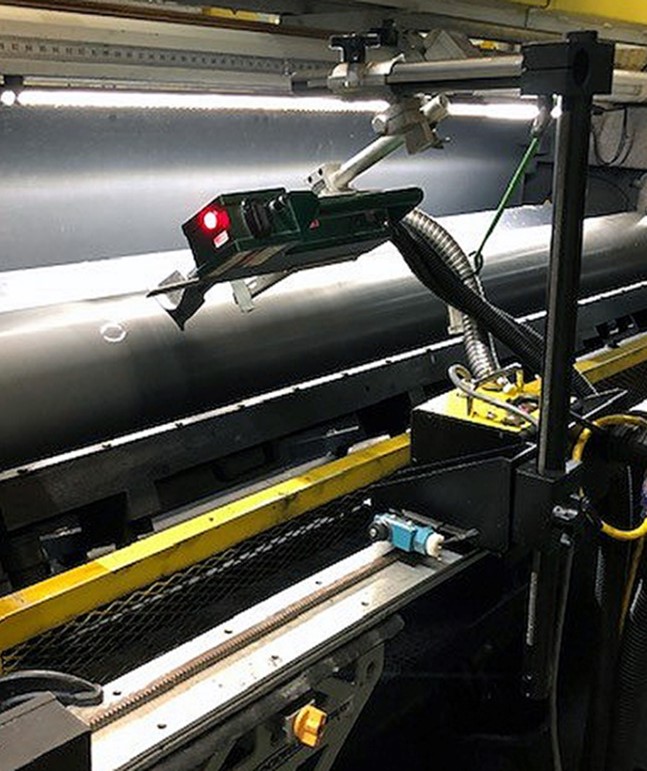

One of the unique advantages of the portable Eclipse Laser Cleaning System is its ability to perform on-press cleaning without disrupting production. This capability is made possible by adhering to industry protocols and using advanced scanning technology.

Creating a Safe Temporary Control Area

Our portable partitions create a defined laser control zone, preventing accidental entry by unprepared personnel. Their collapsible design makes them easy to set up, reposition and store, ensuring minimal impact on workflow.

Rotary Scanner Technology

ARCS’ proprietary rotary scanner ensures uniform energy distribution, avoiding hotspots that could compromise the integrity of anilox rolls. This innovative design maximizes cleaning efficiency while protecting roll surfaces.

Why On-Press Cleaning with Class IV Lasers Works

While enclosed Class I laser systems are common, they lack the flexibility required for on-press applications. The Eclipse Laser Cleaning System combines the flexibility of a Class IV setup with robust safety measures to deliver unparalleled results:

Flexibility: Clean anilox rolls without removing them from the press, reducing downtime and labor costs.

Advanced Safety Protocols: Temporary control areas and strict adherence to NOHD guidelines ensure operator and workplace safety.

Comprehensive Training: Operators receive thorough training on system use, safety measures and best practices.

ARCS: Innovating for Safety and Efficiency

The portable Eclipse Laser System reflects our commitment to advancing the flexographic printing industry. By combining innovation with stringent safety measures, we’ve created a solution that balances performance with peace of mind.

This system has been developed with input from industry experts, rigorous testing, and feedback from real-world applications. The result is a laser cleaning system that meets the demands of modern production environments without compromising safety or efficiency.

The Eclipse Laser System sets a new benchmark for safety and efficacy in anilox roll maintenance. By addressing misconceptions and demonstrating our system's advanced safety features, we aim to empower operators to embrace on-press laser cleaning with confidence.

Ready to experience the Eclipse Laser Cleaning System?

Contact us today to schedule a demo or consult with one of our certified technicians. Let us show you how ARCS can transform your approach to anilox roll maintenance.