Handy Wacks Corporation Improves Safety, Productivity with Goldenrod Lightweight Shafts and Safety Chucks

- Published: March 04, 2025

Goldenrod Corporation, maker of web handling components for converting, has recently worked with Handy Wacks Corporation of Sparta, Michigan to improve safety in their plant and also improve productivity.

Handy Wacks is a family-owned food service packaging company that has been in operation since 1929. They’ve been in their current 80,000 sq ft facility in Sparta, Michigan, since 1952. Handy Wacks manufactures a wide variety of waxed paper products. Their process requires processing large rolls of substrate – and that can take a toll on machinery and keep maintenance teams busy.

Dwight Scheidel, maintenance manager for Handy Wacks, contacted Goldenrod Corporation looking for lighter weight air shafts. Handy Wacks operates three shifts per day, and operators had to lift heavy lug shafts multiple times due to frequent roll changes. Goldenrod’s area salesman, Steve Rogozynski, suggested Dwight try the Model 1263 Carbon Pultrusion design to address the immediate goal of a lighter shaft. The maintenance team at Handy Wacks also found that the Model 1263 Pultrusion was much easier to maintain with the quick-change air bladder design. Handy Wacks now uses these Goldenrod shafts throughout the plant.

While working with Handy Wacks on this project, Goldenrod learned that the safety chucks used on the unwinds and rewinds were wearing heavily. “The problem we were hoping to solve was, what we call “shaft chatter,” where the shaft bounces or does not roll smoothly,” Scheidel explained.

Handy Wacks was using a conventional style safety chuck that seated a hardened square/round shaft journal into the safety chuck replaceable insert. Over time, the metal-on-metal wear can be heard throughout the plant by the clunking noise of the air shafts rotating in the safety chucks. That noise tells the maintenance team it’s time to change the replaceable insert.

With the size of rolls Handy Wacks processes, maintenance teams were devoting excessive time to maintenance. Scheidel and his team needed a better answer: “Rolls would bounce and “tug” on the paper, making it difficult to keep in register,” he said.

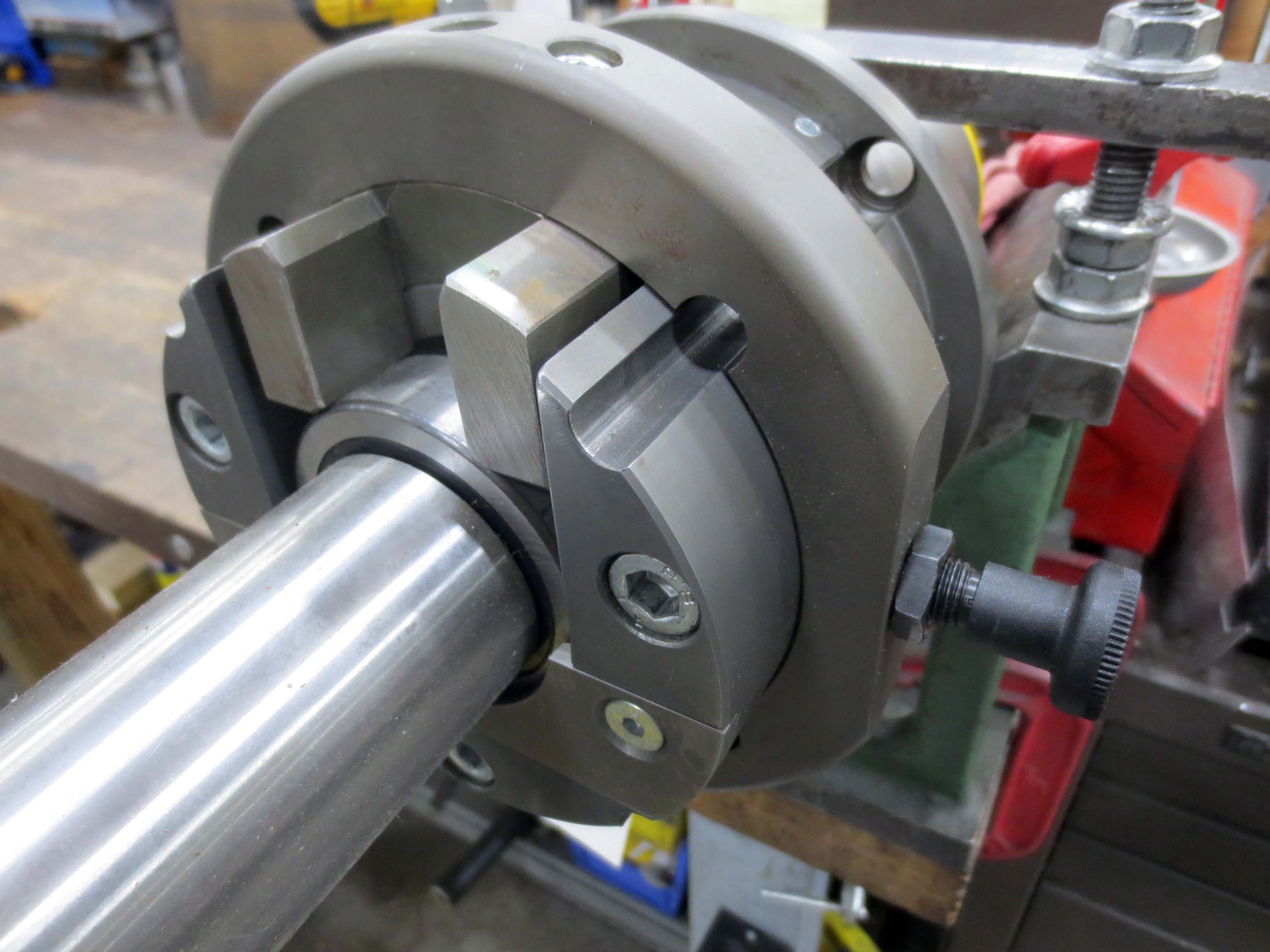

Goldenrod suggested the new Model 928 Safety Chuck as the solution. Metal-on-metal issues have been designed out of this style safety chuck. The Model 928 ingeniously incorporates sockets that support bearings located on the air shaft journals. The outer races of each bearing do not rotate. The closing ring on the safety chucks do not rotate. The result? A safety chuck system that is vibration-free and has longer wear for all components.

“The improvement has been a smoother unwind and less brake wear,” said Jeremy Smith, maintenance technician at Handy Wacks.

For more information on Goldenrod products, visit the company’s website at goldenrodcorp.com.