Color and its Role in Defining Embossed Product Surfaces

- Published: November 07, 2018

Packaging may be the mainstay of business for the majority of converters, but there can be more to converting than packaging. For example, complex plastics, specialized planar films, non-woven textiles, synthetic papers/boards, foils

Packaging may be the mainstay of business for the majority of converters, but there can be more to converting than packaging. For example, complex plastics, specialized planar films, non-woven textiles, synthetic papers/boards, foils

Of course, one must not forget that at the end of the day the finished product still has to be packed and wrapped and the item securely contained—so packaging and labeling is still very much part of the converting remit.

Many of the processes traditionally associated with packaging and prime labeling production are used in the production of finished goods destined for agricultural and horticultural usage, medical/scientific purposes, electronics and electrical applications, automotive, building, construction

Let us consider a process that strides the divide between packaging and industrial and consumer goods, embossing—and the embosser.

A wide range of products may be embossed. Within the realm of packaging, an embossed carton creates a textured surface, which is attractive to look at and touch. Typically, an embossed surface tends to be associated with premium products such as gifts, chocolate boxes, tinned biscuits, etc.

Wallpapers, decorative wraps, kitchen towels

In pharmaceutical applications, embossing can be used for the raised surface synonymous with braille dosage instructions. Embossing is used at times as part of a security program—it can add an extra layer of complexity for counterfeiters and others engaged in forgery to overcome.

An application area for embossing techniques is tissue and toweling. Though some of the paper toweling and toilet tissue produced remains un-embossed, the trend amongst brand leaders of kitchen toweling is to opt for four-color printing and an embossed design as part of their marketing strategy.

An application area for embossing techniques is tissue and toweling. Though some of the paper toweling and toilet tissue produced remains un-embossed, the trend amongst brand leaders of kitchen toweling is to opt for four-color printing and an embossed design as part of their marketing strategy.

The embossing unit comprises varying numbers of embossing rolls and is designed to provide the product with volume as well as personalization. Embossing techniques range from using a steel engraved roll against a flat counter roll, which may be rigid or elastic depending upon the design criteria.

Other methods include using a steel engraved roll positioned against a negative steel engraved roll or alternatively, a steel engraved roll can be used in conjunction with a paper, steel or rubber roller.

Tissue, toweling and non-woven rolled goods may be embossed and flexographically printed. Notwithstanding the difficulties associated with printing color designs at speed on a fragile absorbent substrate, the converter has to make provision for higher levels of linting and dust than in other applications and processes. Inks have to be closely matched and must perform well on press.

Controlling process variables is a must. Dot gain can be made more noticeable due to the substrate, careful fingerprinting is essential and attention must be paid to graphic layout and fidelity of color. In the past, one or two color printing at speeds in the region of 300 meters per minute was the norm. Today a coupling of productivity demands and commercial considerations necessitate speeds in the region of 700 meters as well as four-color printing.

Various quality control devices, ranging from offline proofing or color communication devices to inline automatic inspection systems, enable printers and converters to tackle problems that are simply unacceptable such as poor color registration, streaking, spotting, pin holing, problems associated with inks, color variability, printability issues and much more.

Embossing is also widely used in another more traditional application area where complex embossed patterns are involved, usually in wallpaper or wall covering production.

Wallpapers often have random complex patterns, defects can sometimes be difficult to detect, particularly color shade differences. With wall coverings and other patterned decorative surfaces, flaws and subtle variations in color have a habit of only becoming noticeable when the wall covering is being hung.

For products that depend not only on how they perform but how they look, manufacturers and their suppliers use a variety of process monitoring and quality control devices for trialing inks, coatings

Pilot coating/printing and laminating systems such as RK Print Coat Instruments Rotary Koater and customer bespoke VCM have a part to play as do proofing and color communication devices, like the FlexiProof for users and producers of flexographic inks and the K Printing Proofer. The latter can produce proofs for comparison purposes using flexographic, gravure and offset-gravure inks.

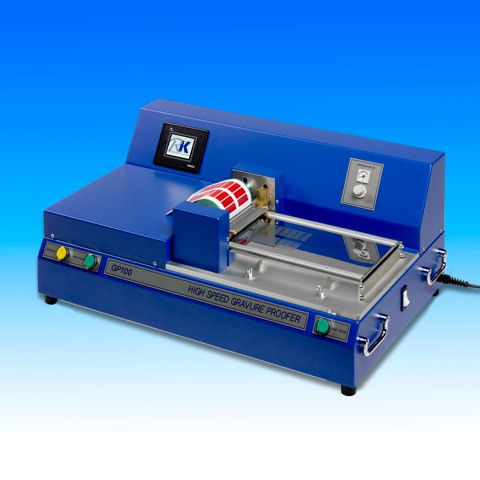

The GP100 is another product in the lineup of proofing and color communication devices. This is a compact benchtop unit for the production of proofs using gravure inks of press viscosity. The GP100 can be used for research and development, color matching and quality control purposes.

Regarding the award-winning FlexiProof—this device, whether sited in a laboratory, in a dedicated pre-press environment, next to a press or located in the quality control department of an ink manufacturing plant, is used for color matching, the trialing of new or unfamiliar materials, research and development and to determine printability.

A scaled down but component critically exact version of a flexo press the FlexiProof helps minimize on production machine waste maximizes production machine uptime and speeds product development by enabling many variables to be detected quickly and bought under control off

The family is comprised of three variants, the FlexiProof 100, FlexiProof UV and FlexiProof LED UV. The UV versions are equipped with an integrated, miniaturized UV system enabling an operator to print (proof) and cure in line.

About the Author

Tom Kerchiss is with RK Print Coat Instruments, Royston, Hertfordshire, UK, a manufacturer of the VCM (Versatile Coating Machine) and the Rotary Koater, which are utilized by many Blue Chip companies to speed product development.

Do not forget to visit the online copy of our monthly print magazine and sign-up to subscribe.