There’s More than One Way to Treat a Film

- Published: June 27, 2022

By Ted Lightfoot, casting, coating, drying and laminating film consultant

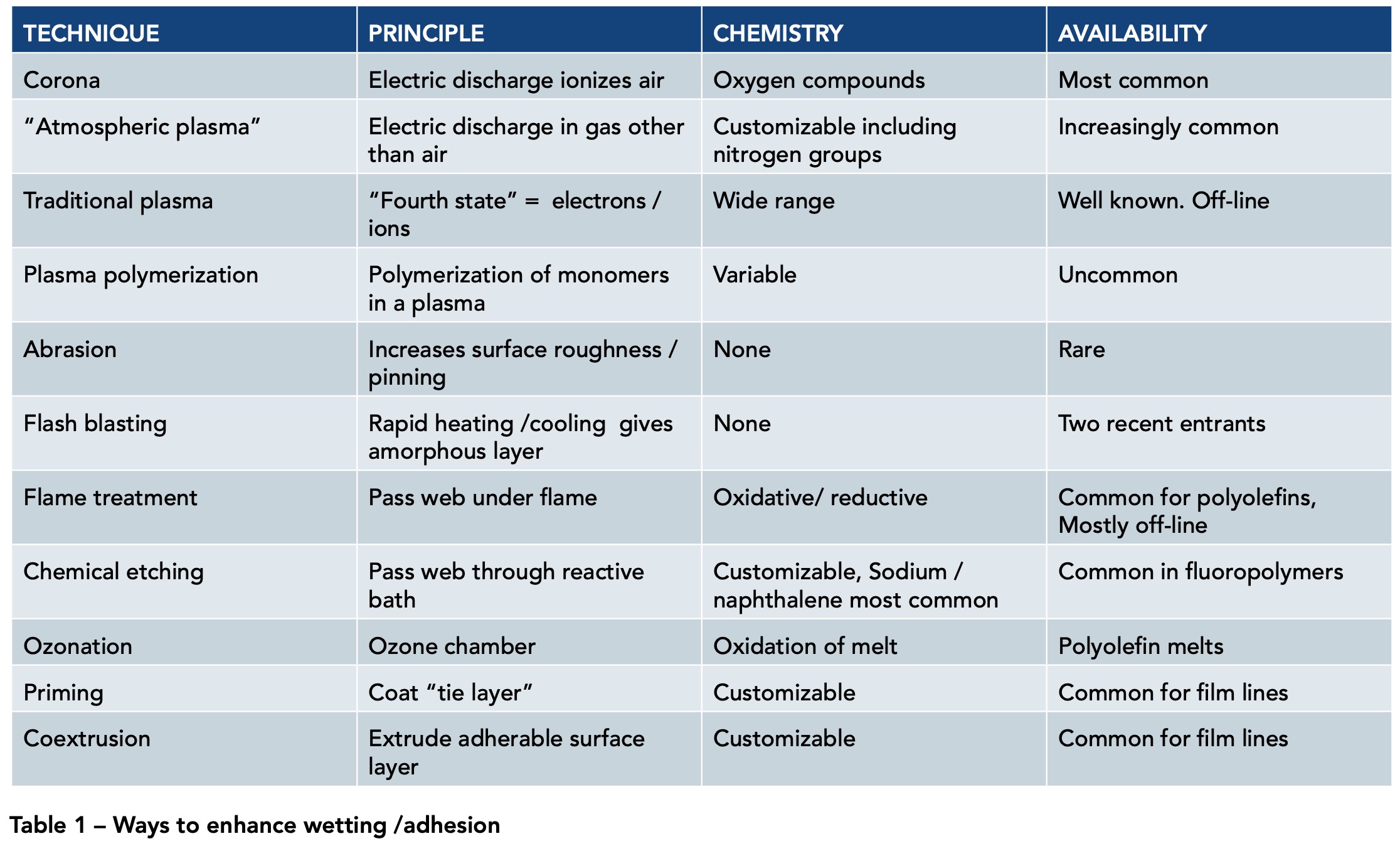

To most people, surface treatment means corona treatment. Corona treatment is the most popular surface treatment for good reasons, but it isn’t the only choice. Table 1 lists 10 other ways to improve wetting and adhesion. But, before getting into the “how,” you need to establish the “why” ... Are you looking for better wetting or better adhesion?

Printers need to control dot size, so they have to control wetting. Usually that means “surface energy” although liquids can be pinned by roughening the surface. Abrasion to enhance roughness is not common, but buying rougher film is.

Most people use “dyne pens” containing mixtures of 2-ethoxyethanol and formamide (specified in ASTM D-2578-04a) to see which wet (for three seconds) and which bead up. Contaminated dyne pens can give false reading, so be careful what they touch.

The ASTM method (drops of liquid on clean swabs) is a better choice if contamination is an issue. D-2578 was written for polyethylene and polypropylene. ASTM D7490-13 was written for more polar substrates (like polyester). There are small portable measuring devices for D7490 — but no pens.

Coaters need the liquid to wet the surface, but they also need adhesion. The most robust mode of adhesion is covalent bonding, so they try to introduce reactive groups on the surface (which, coincidentally raise the surface energy). Most techniques listed in Table 1 are aimed at improving adhesion through introducing reactive groups.

One exception to that is “flash blasting” — developed for polyester. It is hard to stick to crystalline materials. Exposing the film to a “flash” of intense light quickly melts the surface leaving an amorphous adhesion promoting layer.

In both corona and atmospheric plasma treating, the web passes between a grounded roller and an electrode driven at a high frequency and voltage. This produces a glow discharge over the film.

In air, this discharge produces reactive oxygen species (including ozone — that you have to decompose before venting). Either the electrode or the grounding roller must be insulated to prevent arcing. Before corona, people used “spark treatment” or “electronic discharge” to enhance wetting and adhesion. The great innovation for corona treatment was increasing the AC frequency from 50-60 Hz to 20-80 kHz [US Patent 3,514,393] (although most corona treaters run between 15 and 25 kHz).

Atmospheric plasma frequencies usually run between 40 and 100 kHz although some use 13.56 MHz or 2.45 GHz. The advantages of higher frequency are “depth” of the treatment (for plasma, that can include removing a weak boundary), minimization of the possibility of “lightning bolts” (point discharges that leave pinholes in the film) and back side treatment (generating a plasma on the back side of the film under a wrinkle).

Atmospheric plasma treaters use gases other than air and can produce many types of surface chemistry (e.g., nitrogen groups) as well as the oxygen containing groups generated by corona [US Patent 3,274,091 predates the term “atmospheric plasma” by some decades, but describes many atmospheric plasma systems.].

There is a lot of confusing marketing for atmospheric plasma and “plasma ready” corona treaters. If you are considering atmospheric plasma, be clear what you are getting: Is this just a corona treater with gas seals; How high is the frequency? How much of the web path is covered by the plasma? What gases can it handle? How effective is it for surface cleaning, etc. Engineers tend to favor the highest performance system, but the least expensive one may satisfy your needs.

It has been known since the late 19th century that low pressure plasmas can react with surfaces and form new materials (including polymers) [The Foundations of Vacuum Coating Technology, Donald M. Mattox Berlin Heidelberg: Springer Verlag (2003)]. Vacuum plasma is powerful, but not an on-line option. Reactive atmospheric plasma treaters [US Patent 6,118,218] became available around 2000. These can create a wide range of chemistries and substrates — at a cost.

Another off-line option, very effective for halogenated polymers, is chemical etching (running film through a bath of metallic sodium in naphthalene).

Flame treatment involves passing the film (quickly) under a flame with a controlled chemistry. Like plasma treating, flame treating can clean off weak boundary layers. Flames can be run oxygen rich, or fuel rich to adjust the surface chemistry for the application. Flame treatment is usually run off-line; however, on-line flame treatment is common for BOPP lines. It is not cheap to install and it presents safety challenges, but it is very effective and often produces longer treatment life than corona.

The last three techniques in Table 1 are not exactly surface treatments of the film: ozonation involves exposing the melt in an extrusion coater to ozone to introduce reactive groups on the melt. Priming and coextrusion are usually practiced before the film comes to the converter.

If done as an add-on, priming is expensive. But many film manufacturers use coextrusion and on line-priming to produce a more wettable and adherable base (quite economically). Sometimes the cheapest option is to get someone else to do it.

Which surface treatment is “best?” Usually, the cheapest one that works for your applica- tion. On-line corona treatment is usually the lowest cost option and works for most systems. It is hardly surprising that corona is the most common method. Corona does not work for all systems but if it doesn’t, remember: You have other options.

1 US Patent 3,514,393

2 US Patent 3,274,091 predates the term “atmo- spheric plasma” by some decades, but describes many atmospheric plasma systems.

3 The Foundations of Vacuum Coating Technology, Donald M. Mattox Berlin Heidelberg: Springer Verlag (2003)

4 US Patent 6,118,218

About the Author

Ted has worked in coating, drying, laminating, and film casting for over 35 years. He has experience in R&D, plant support, as a Six Sigma Black Belt for Growth, and application development (helping customers develop processes and structured products). He is a consultant, writer, speaker, and gives short courses. He can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..