Cutting-Edge U.S. Installation of New Web Offset Press Helps Pioneer LED UV Curing in Book Printing

- Published: July 18, 2023

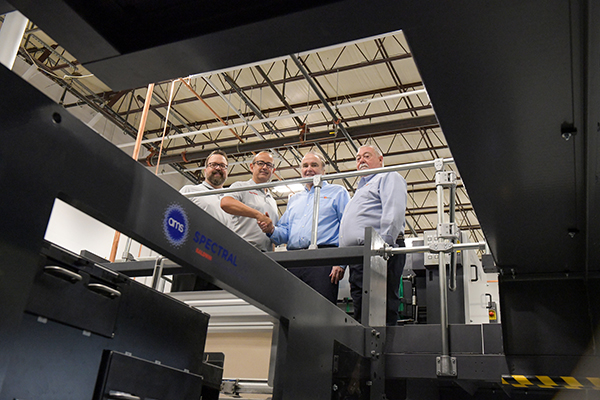

North America’s newest high-speed web offset press doesn’t have a gas dryer. Thanks to a pioneering purchase by Bradford & Bigelow of a Manroland Goss Lithoman IV press equipped with an advanced LED-curing system from Baldwin Technology’s AMS Spectral UV brand. This combination of companies has brought a new leading edge to the high-speed web offset market.

Bradford & Bigelow, based in Newburyport, Massachusetts, is one of North America’s leading printers of 8.5 x 11-inch textbooks and workbooks used for K-12 education. The new press is its second Lithoman. According to the printer, after producing books for years on a Lithoman, it was an easy decision for B&B to choose another Manroland Goss press.

B&B has been a pioneer in the use of UV inks. Several years ago, the printer converted its sheetfed and Timsons web presses to AMS Spectral UV’s LED UV ink technology successfully. However, the technology had not been perfected for higher-speed webs like the Manroland Goss that run north of 30,000 impressions per hour.

Since then, LED UV ink technology has continued to improve and the B&B team along with St. Louis, Missouri-based Baldwin and Manroland Goss, headquartered in Augsburg, Germany, decided the time was right for B&B to be the beta site for this breakthrough technology on higher-speed web presses.

LED curing offers process improvements like instantly cured ink, shorter make-readies, and less paper waste, plus environmental and safety benefits, a significant reduction in energy consumption, no VOCs or need to exhaust oven air, and many more. But the most obvious change is replacing a 45-foot oven and chill unit with a 36-inch LED system.

“It’s like replacing something longer than a school bus with something the size of a barbecue grill,” stated Craig Black, Baldwin VP Sales, Americas.

Printers may wonder if they will have to give up press performance when they move to LED.

“Not at all,” said Jonathan Fore, Director of Product Management at Baldwin. “Our XP Quatro LED system is powerful enough to run these wide, high-speed web offset presses as fast as you can.” Bradford & Bigelow confirmed this, saying that the newly commissioned press is running well over 30,000 impressions an hour, with the LEDs not even set to full power.

Using LED curing on a new, high-speed web offset press was so unique that Bradford & Bigelow needed to make sure there would be enough LED ink for the millions of schoolbooks they print each year. The printer found what it needed from Universal Color. The Woburn, Massachusetts-based company not only proved its LED ink would cure at top press speeds, but also guaranteed B&B’s annual supply of inks.

“This breakthrough technology was possible because Bradford & Bigelow, Manroland Goss, Baldwin’s AMS Spectral UV and Universal Color worked together as a team to ensure its success,” Bradford and Bigelow CEO John Galligan commented. “And yes, the team is delighted with the results!”

Watch Printing Impressions’ interview with John Galligan about the installation and partnership here.

Visit baldwintech.com to learn more.