New Release Liner: Sol BCK Helps Reduce Carbon Footprint by More than 50 Percent

- Published: July 14, 2023

Sappi Europe, one of the world’s leading manufacturers of packaging and speciality papers, aims to support its customers in achieving their own sustainability goals. At this year’s AWA Global Release Liner Industry Conference & Exhibition in Denver (USA), Sappi Europe presented its new Sol BCK release liner for visual communication and industrial applications as well as for adhesive tape products. Produced in Alfeld (Germany), the release liner promises an improved carbon footprint by eliminating plastic coating, better recyclability by saving plastic material and cost savings – compared with the PCK-based (Polyethylene Coated Kraft) release liner.

Gunnar Sieber, Head of Sales CCK Papers at Sappi Europe, explains: “We developed the new BCK liner with a clear focus on the American market. PCK papers currently dominate there as a backing material for visual communication adhesive applications. With PCK papers, a plastic polyethylene (PE) coating on the reverse side protects against moisture. But applying PE is detrimental to the later recycling of PCK papers. With BCK paper, we aim to provide an alternative that excels in terms of carbon footprint.”

Special surface coating improves the flatness of the self-adhesive bond

The new Sol BCK release liner features a clay coating that ensures a smooth surface. This makes it ideal for siliconization. Furthermore, Sappi developed a functional coating that dispenses with polyethylene, while still minimising moisture penetration.

Significantly reduced carbon footprint compared with PCK papers

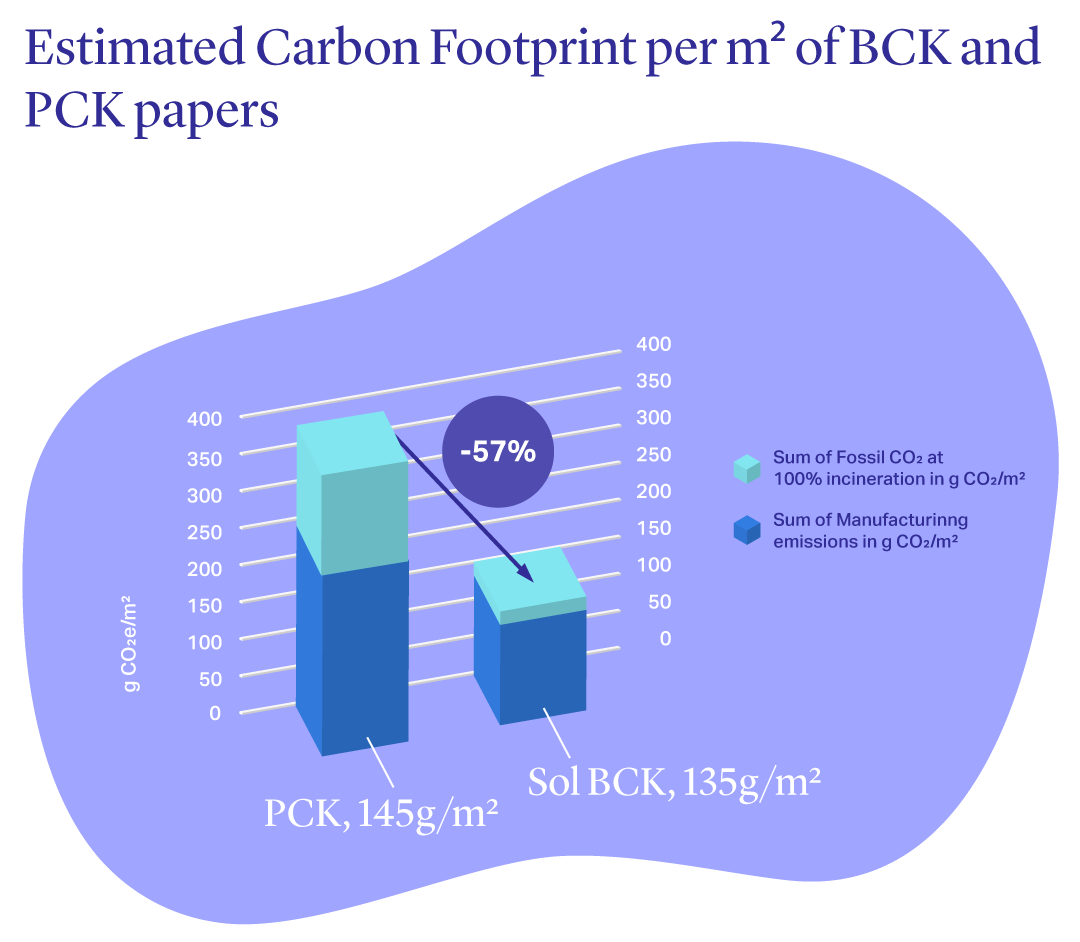

As internal tests demonstrate, the applied functional coating on the new Sol BCK paper is significantly more environmentally friendly because the new releae liner type does not have a polyethylene layer. Sappi calculated the CO2 consumption of both backing papers and the results are impressive: The production of Sol BCK saves up to 57 per cent of CO2 emissions compared to PCK. And costs can be further reduced thanks to material savings in grammage and a significant reduction in polymer content.

Sol BCK delivers convincing results in processing

The properties of the new release liner were also convincing: For example, the new BCK not only demonstrates good dimensional stability and flatness, but also as much bond strength as a common PCK paper. Especially in terms of heat resistance in the siliconization process and surface strength during plotting, where the BCK has a clear advantage over the PCK.

In spite of all the advantages of the new product, Sappi is keen to point out that the new Sol BCK paper is not intended to replace PCK. Wolfgang Hoffmann, Senior Application Expert Self-Adhesive & Flexible Packaging Solutions at Sappi Europe, said: “With our new Sol BCK release liner, we are offering a viable and more environmentally friendly alternative.”

Project partners for industrial testing are welcome

Sappi has already won over partner companies for the new release liner, who are testing the Sol BCK for numerous applications under standard market conditions. At the Labelexpo Sappi will present the latest news of the Sol BCK in hall 5, stand B13.

Learn more about Sappi at www.sappi.com.