LAEM IMS – Slitting and rewinding solutions always keeping pace with the evolving needs of the converting industry

- Published: February 20, 2024

LAEM IMS is a manufacturer of slitter rewinders established in 1972 that has grown significantly to become a key player in the design and manufacturing of equipment used in the converting industry. Since 2020, LAEM has been a part of the IMS TECHNOLOGIES Group, enriching the company’s portfolio with extensive expertise in the flexible packaging sector.

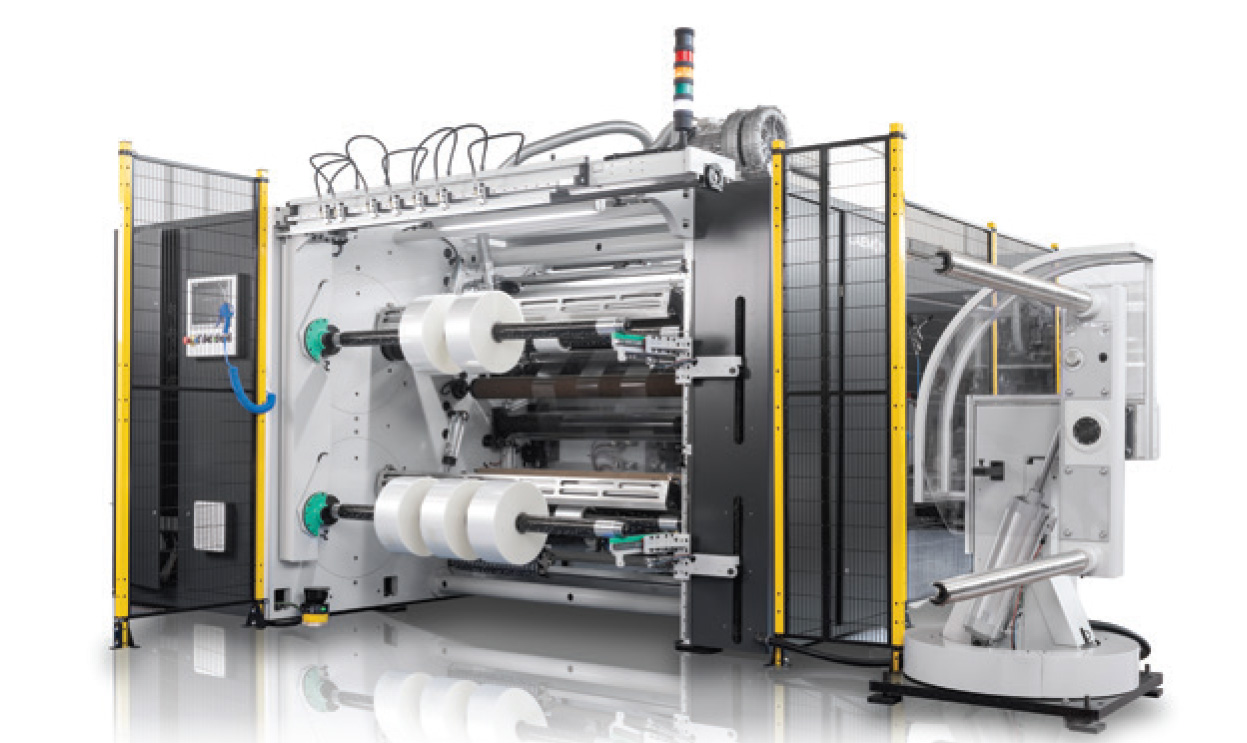

The product portfolio of LAEM IMS includes twin-shaft, turret, and compact slitter rewinders, along with technologically advanced end-of-line full automation systems essential for processing various flexible packaging materials as well as paper, film, laminates, aluminum, and coated materials. The brand excels also in fully integrated automated solutions, positioning itself as a pioneer in automation and robotics.

LAEM IMS dual shaft and turret solutions for the flexible packaging industry

Dual Shaft slitter rewinders

LAEM IMS’s dual shaft solutions are meticulously designed to rewind and produce high-quality finished reels with large diameters. The benefits of choosing a dual shaft machine include increased productivity, perfect tension control, cost reduction, high production quality, great flexibility, and high reliability.

Turret Solutions

The turret slitter rewinders from LAEM IMS are engineered to achieve high production speeds. Coupled with the automatic change-over feature, these solutions drastically reduce machine downtimes, with the ability to restart in less than one minute. The advantages of choosing turret slitter rewinders include: no machine downtimes, increased productivity, a seamless production cycle, high-quality finished reels, and a center-driven configuration.

Highlighted Series in the Portfolio

Within our portfolio, two series stand out: the RIBOSLIT series and the RB series.

RIBOSLIT SERIES: a unique design, synthesis of quality, performance and safety

The RIBOSLIT Series caters to film manufacturers and converters seeking to combine reduced operational space and investment with top-notch components. This series includes the compact dual shaft slitter rewinder, RIBOSLIT 2, and the compact double turret slitter rewinder, RIBOSLIT 4. Boasting an innovative and ergonomic design, along with a revamped operator-friendly software and HMI, the RIBOSLIT Series can rapidly process a wide range of films and laminates within the flexible packaging industry.

Both RIBOSLIT 2 and RIBOSLIT 4 share identical features, ensuring a minimal footprint and high efficiency. However, their configurations differ, providing the RIBOSLIT Series as a versatile solution tailored to meet each customer’s unique production requirements.

RB SERIES: Converting has never been so easy

The RB 2 slitter-rewinders, with their extensive array of accessories and highly flexible configurations, are carefully crafted to fulfill the production requirements of the converting industry. Leveraging center-driven winding technology and state-of-the-art differential shafts, these machines enable the production of very narrow reels while maintaining consistent tension and hardness across the entire width.

Designed specifically for film manufacturers and converters aiming to produce multiple finished reels with relatively small diameters, the RB 4 offers a significant reduction in cycle downtime compared to a dual shaft machine. This is achieved by minimizing change-over time and establishing an efficient production rhythm for operators. The standard configuration includes two rewinding motors for independent control of the upper and lower shafts.

In summary, LAEM IMS, through its commitment to innovation and a diverse product range, plays a crucial role in advancing the capabilities of the flexible packaging industry. The brand’s offerings prioritize efficiency, reliability, and cutting-edge technology, meeting the evolving needs of manufacturers and converters on a global scale.